bracconiere

Jolly Alcoholic - In Remembrance 2023

For some reason i'm still dying to know if my trick works for everyone, or if it's just me.

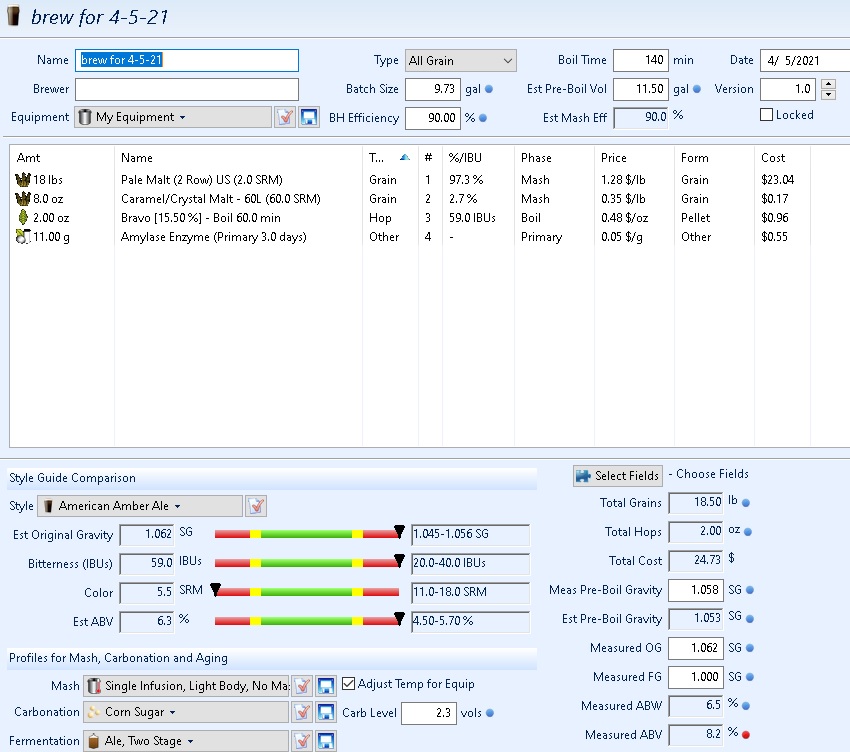

I do a step at, well i add gluco, so the first step isn't important to me. but then i pull off some of the mash and boil it, add it back a few times, till my mash is 162f. i go from 83% effec to 92% doing this.

i want someone else to try this that keeps track of their effec, so i know if it's a good trick for better effec. or just shut up, and sit down! lol

anyone willing to try next brew?

I do a step at, well i add gluco, so the first step isn't important to me. but then i pull off some of the mash and boil it, add it back a few times, till my mash is 162f. i go from 83% effec to 92% doing this.

i want someone else to try this that keeps track of their effec, so i know if it's a good trick for better effec. or just shut up, and sit down! lol

anyone willing to try next brew?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)