kerant

Well-Known Member

Taking a poll! Want to build a manifold mash cooler and want to know know which you think is best - copper or pvc? If any of you have done both which did you find worked best? Thanks

I'm leaning towards copper. You got any pics? I already have a brass tap but my concern is getting it to have a nice snug fit on the cooler with the manifold inside. Any advice?

What kind of cooler?

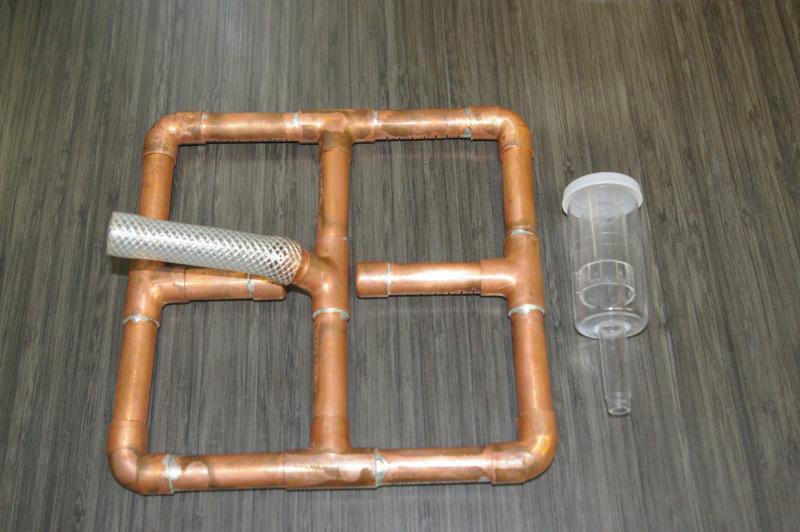

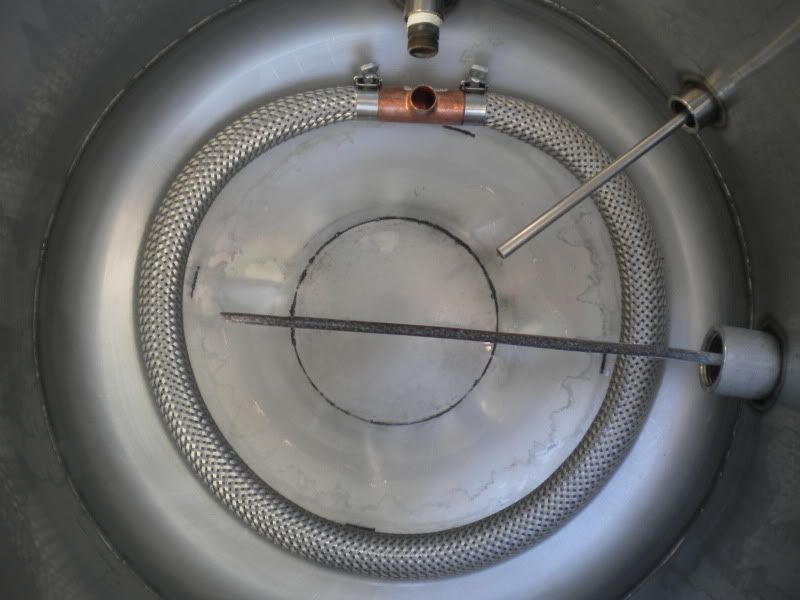

I made mine for a 48 Quart rectangular cooler:

I'm leaning towards copper. You got any pics? I already have a brass tap but my concern is getting it to have a nice snug fit on the cooler with the manifold inside. Any advice?