After boiling I used gloves for everything.

That's not really necessary. Just don't touch sanitized surfaces your wort or beer will touch.

And for first time I use plate chiller for worth...this I amazing...from boiling to 21 degrees in 35 minutes! Wow

Plate chillers are indeed awesome in their chilling duties.

But... one and important point of advice:

Do

NOT ever let hop particles, or Irish Moss, or fruit pulp, or any other such course materials go inside the plate chiller. Seriously!

If they are allowed to go in there, chances are they will remain there, and are very difficult (read: nearly impossible) to completely clean out.

To avoid getting any foreign material inside your plate chiller (and staying in there, or even plugging it up), it's best to bag all your hops and other additions that

aren't very fine powder or dissolve. I mean literally, bag

anything and

everything, such as hops, fruit, (dried) orange peel, Irish Moss, etc. Use large, fine mesh nylon "hop bags." Stick a few glass marbles or a stainless coupler in there to keep them submerged.

In addition to using bags, it's also recommended to put a good (fine mesh) stainless filter on the exit port, inside your kettle, just to catch anything that made it outside the bags.

Speaking from 15 years experience using plate chillers, and keeping them clean.

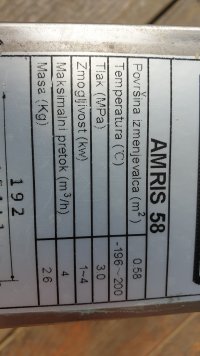

Can you post a picture of your plate chiller?

If it's all stainless, no plastic parts, you can bake it in the kitchen oven at 175-250°C (350-450°F) for a few hours to sterilize it. You can stick a couple loafs of bread in with it.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)