Pricey relay.. But it works is the important part! So you are using a BCS, and an Arduino, plus that Relay board? What is the arduino controlling? I was trying to use some relays with my arduino for a dry cure chamber project and I could never get it working. Could be the same issue, even though says it works with arduino....

http://www.amazon.com/gp/product/B00E0NSORY/?tag=skimlinks_replacement-20

By the way, I cannot find that link you sent about the float switches for the life of me. Can you resend please!

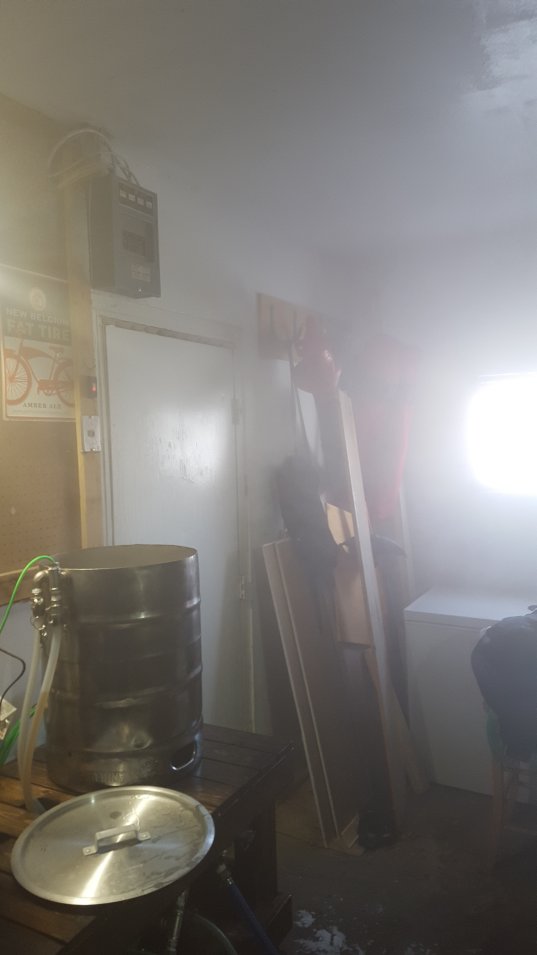

So when do you think you'll be able to fire it up? My setup is coming along still but had to order some last minute fittings I hadn't thought about. I don't think that my first brew session I'll be able to take advantage of the remote fill and pre heat capability.

More importantly, what the first beer you're planning to brew?

TD

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)