Before we get started I would like to say a few things. First off, I suck at spelling so brace yourself and lets hope some spell check can get us through this. Secondly, I love me some pictures, so be prepared for that. My build is what I will consider a giant combination of lots and RAD from the HBT community so thanks to everyone else out there that has posted pictures and explanations of their brewery, it really helps and I hope I can return the favor and do some brew systems out there justice. With that, lets get this train moving.

My current system is ugly but works and makes great beer, but Im tired of slumming it with propane and figured I'm defiantly in this hobby for the long haul so its time IMO to clean it up and make it easier to brew on. However im still stuck in the garage, without plumbing so its still going to need me to move RO water and drag a hose in for cleanup.

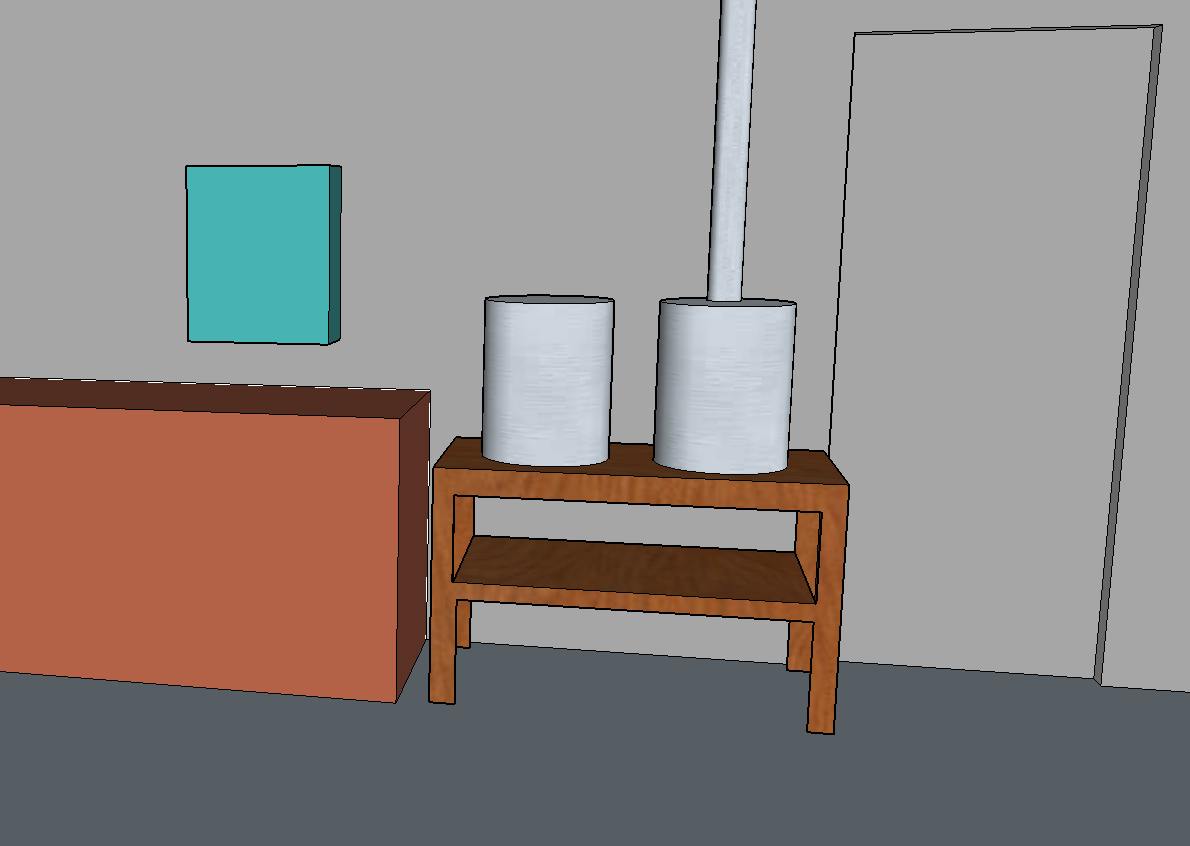

This is the new location for my Electric BCS System.

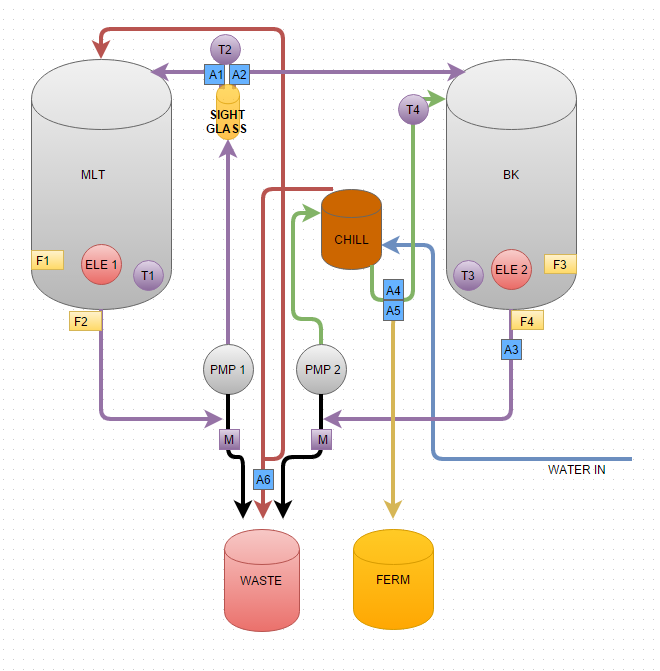

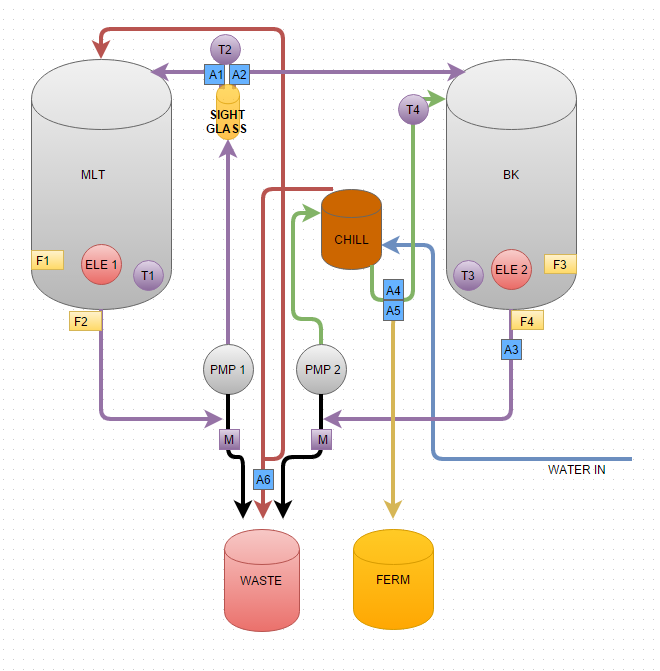

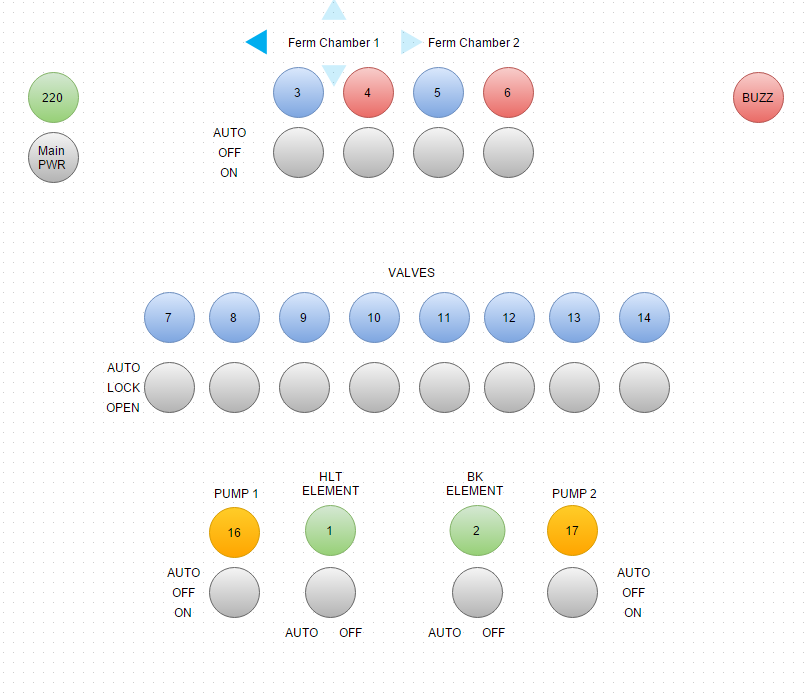

Lots of work needs to be done, including but not limited to getting 30 amp outlet to the garage, building stand, making some bottom drain keggles from yet to be sourced kegs, building a full control panel and probably waiting on 100 orders from china to show up to my door. I have already started electric work and will get some pics of that up in the next post. I hope you guys enjoy. Here is proposed design for the new system for those who want a glimpse into the future.

Cheers.

My current system is ugly but works and makes great beer, but Im tired of slumming it with propane and figured I'm defiantly in this hobby for the long haul so its time IMO to clean it up and make it easier to brew on. However im still stuck in the garage, without plumbing so its still going to need me to move RO water and drag a hose in for cleanup.

This is the new location for my Electric BCS System.

Lots of work needs to be done, including but not limited to getting 30 amp outlet to the garage, building stand, making some bottom drain keggles from yet to be sourced kegs, building a full control panel and probably waiting on 100 orders from china to show up to my door. I have already started electric work and will get some pics of that up in the next post. I hope you guys enjoy. Here is proposed design for the new system for those who want a glimpse into the future.

Cheers.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)