You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BCS 2 Vessel No Sparge Garage Brewery Build

- Thread starter poptarts

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BeardedBrews

Well-Known Member

I always thought it was cool when people mount a window in the front of the panel so they can see the BCS mounted inside. Completely non-functional, but if you're spending time on cable sleeves it sure would look sharp!

-B

-B

BeardedBrews

Well-Known Member

I wasn't planning on sleeving the inside, but yea that would be getting close to PC mod awesome, toss a black light in there.

All surface mount is still an option! I have faith in you.

http://www.overclock.net/t/1424387/gallery-build-log-ultimate-wall-mount-rig-maxxplanck-v2-completed

BeardedBrews

Well-Known Member

Ill see what I can do lol

Beer (yellow liquid) cooled SSRs would be awesome, you could convert a pint glass into a reservoir. The sleeving could be a mix of yellows and browns to stay on theme.

I'll just wait here patiently.

[/taps foot]

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

30Bones

Well-Known Member

Very cool build. Pardon any ignorance, but why not just go BIAB?

Just trying to wrap my head around this as I am wanting to go e-BIAB and have the start of a bottom drain keggle I would like to use since it was free, but feel it's too small to do 10 gallon batches any higher than 1.040-45. Maybe I am wrong there? For the time being I plan to electrify it and mash in my 70qt cooler and use the keggle for HLT and BK like I do now only on propane

Just trying to wrap my head around this as I am wanting to go e-BIAB and have the start of a bottom drain keggle I would like to use since it was free, but feel it's too small to do 10 gallon batches any higher than 1.040-45. Maybe I am wrong there? For the time being I plan to electrify it and mash in my 70qt cooler and use the keggle for HLT and BK like I do now only on propane

BeardedBrews

Well-Known Member

Too small to do 10 gallon batches any higher than 1.040-45.

I haven't tried it, but for a 10g batch size I should theoretically be able to get a full volume mash of 1.050 OG in my 15.5g keg assuming I can hit 75% efficiency and don't lose more than ~0.5g in the tubes and trub.

That said, I am not particularly offended by the idea of tossing 1-2 gallons of filtered water back into the kettle before I start the boil. For that same 10g batch I should be able to fit 1.085 in my BIAB if I plan to add 2 gallons after I pull the bag. If I mash to the top of the keg that puts me at 3l/kg which is fairly thick, but not unreasonable. I'm not sure I'd hit my 75% target and I am quite sure that stirring up that 35# grain bill would be a PITA!

one other thing to keep in mind is the dead space below the element when you BIAB. If you want to heat and recirculate during your mash you'd have to figure out something to get the bag off the element which will reduce your mash volume (thicken your mash) considerably.

30Bones

Well-Known Member

That's my biggest limiting factor using a keggle. I want bottom drain, but also think I would be ticked if I built a keggle and then realized I should have bought a 20 gallon and a basket over a bag from the start.I haven't tried it, but for a 10g batch size I should theoretically be able to get a full volume mash of 1.050 OG in my 15.5g keg assuming I can hit 75% efficiency and don't lose more than ~0.5g in the tubes and trub.

That said, I am not particularly offended by the idea of tossing 1-2 gallons of filtered water back into the kettle before I start the boil. For that same 10g batch I should be able to fit 1.085 in my BIAB if I plan to add 2 gallons after I pull the bag. If I mash to the top of the keg that puts me at 3l/kg which is fairly thick, but not unreasonable. I'm not sure I'd hit my 75% target and I am quite sure that stirring up that 35# grain bill would be a PITA!

one other thing to keep in mind is the dead space below the element when you BIAB. If you want to heat and recirculate during your mash you'd have to figure out something to get the bag off the element which will reduce your mash volume (thicken your mash) considerably.

poptarts

Well-Known Member

Very cool build. Pardon any ignorance, but why not just go BIAB?

Just trying to wrap my head around this as I am wanting to go e-BIAB and have the start of a bottom drain keggle I would like to use since it was free, but feel it's too small to do 10 gallon batches any higher than 1.040-45. Maybe I am wrong there? For the time being I plan to electrify it and mash in my 70qt cooler and use the keggle for HLT and BK like I do now only on propane

The main reasons i'm not going BIAB is for automation. Plus BIAB makes a ton of trub and that weirds me out for some reason. But you are correct something could be done like this BIAB style and it would be a decent amount simpler.

Hey pop tarts if your panel has switches on it, give it a long hard thought if that's what you really want. More switches, lights, etc. requires more hardware, more wiring, more cost, more troubleshooting, more room for failure, more space, and more commitment. Just throwing it out there. The interface is easy to turn things on and off, and assuming you have the connectors built in, expansion is easy. I kept my hardware to a minimum to allow for future expansion without killing myself!

-BD

-BD

poptarts

Well-Known Member

Hey pop tarts if your panel has switches on it, give it a long hard thought if that's what you really want. More switches, lights, etc. requires more hardware, more wiring, more cost, more troubleshooting, more room for failure, more space, and more commitment. Just throwing it out there. The interface is easy to turn things on and off, and assuming you have the connectors built in, expansion is easy. I kept my hardware to a minimum to allow for future expansion without killing myself!

-BD

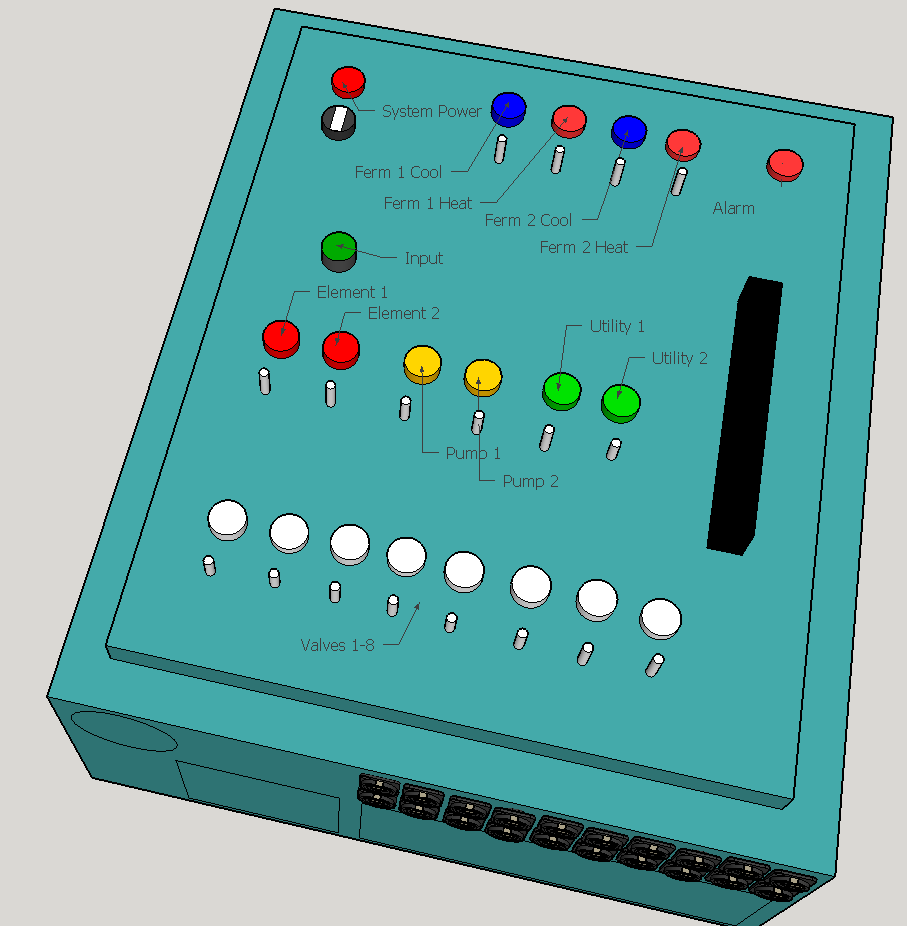

So what do you think? Power / Elements / Pumps / Alarm

Hold off on everything else for now?

Well, first just think about what you really need and if you might want to change it in the future. Wiring in extra lights and switches is no small task.

I just have power and element on LEDs, a power keyswitch, an Estop, and an alarm. There are times when I would like to turn the pump on and my iPad isn't handy. So I just whip my phone out and use it, but some might see the value in a pump switch. Other than than I like having everything in the soft interface.

I just have power and element on LEDs, a power keyswitch, an Estop, and an alarm. There are times when I would like to turn the pump on and my iPad isn't handy. So I just whip my phone out and use it, but some might see the value in a pump switch. Other than than I like having everything in the soft interface.

I bought four stainless ball valves with low voltage DC control (open when voltage applied) via eBay. They were fairly inexpensive. Under $40 as I recall?? 1/2" full port female pipe threaded.

Frankly, aside from remote filling the HLT and beginning heating using BCS, I don't currently see what major advantage I personally would get from further automation. For one thing, you sort of need to be there in order to brew. It might be nice to someday get some three way valves to bypass some hose swaps I'll need to do (which I assume will result in spillage and sticky mess that I'll need to mop up). Even still I would need to be there to supervise, and I cannot imaging that is inexpensive to get automated three way valves, so most likely these will be manual. Also I imagine adjusting the recirculation rate to avoid a stuck mash would be better accomplished manually. Someone here or another thread was claiming to run valves and pumps wide open however...

TD.

Frankly, aside from remote filling the HLT and beginning heating using BCS, I don't currently see what major advantage I personally would get from further automation. For one thing, you sort of need to be there in order to brew. It might be nice to someday get some three way valves to bypass some hose swaps I'll need to do (which I assume will result in spillage and sticky mess that I'll need to mop up). Even still I would need to be there to supervise, and I cannot imaging that is inexpensive to get automated three way valves, so most likely these will be manual. Also I imagine adjusting the recirculation rate to avoid a stuck mash would be better accomplished manually. Someone here or another thread was claiming to run valves and pumps wide open however...

TD.

poptarts

Well-Known Member

Where did you buy your valves from ? I'm trying to find a place with stainless that doesnt cost an arm and a leg. Automation would be great, just dont want to spend so much on a system.

Thanks!

23 each

http://www.ebay.com/itm/1-2-1-DC12V...hash=item2336b5d3da:m:mS1vyx5hoTZJqRRa_9gKNUw

poptarts

Well-Known Member

Well, first just think about what you really need and if you might want to change it in the future. Wiring in extra lights and switches is no small task.

I just have power and element on LEDs, a power keyswitch, an Estop, and an alarm. There are times when I would like to turn the pump on and my iPad isn't handy. So I just whip my phone out and use it, but some might see the value in a pump switch. Other than than I like having everything in the soft interface.

Keep it simple keep it safe. I can always add more so ill trust ya and go simple first.

Because I put a bunch of XLR connectors in my control box it was just a matter of wiring them up as I added. I am just finishing my electric valves. After some testing my next project will be to install an RPi into my control console for a permanent interface. These were "envisioned" as possibilities early on but I have let my brewing experiences guide my needs/goals and next directions. I am finding that more incremental automation is allowing me to focus more on brew science.

-BD

-BD

poptarts

Well-Known Member

Because I put a bunch of XLR connectors in my control box it was just a matter of wiring them up as I added. I am just finishing my electric valves. After some testing my next project will be to install an RPi into my control console for a permanent interface. These were "envisioned" as possibilities early on but I have let my brewing experiences guide my needs/goals and next directions. I am finding that more incremental automation is allowing me to focus more on brew science.

-BD

Yea I have 20 XLR and 8 l15-5rs that will be going into the panel for sure. But yea no need to chop a bunch of holes for lights and switches if I dont need them. Can always add them or something else later if needed. Plus like you said, less work and less to break all around.

CarbonTom

Well-Known Member

- Joined

- Feb 18, 2014

- Messages

- 338

- Reaction score

- 38

Got some plugs for the elements. And some special fittings from one of everyone's favorite hardware store.

Did you make this sight glass on your own? Or did you buy? If so how/where??

Awesome build man!

poptarts

Well-Known Member

Just got word that BCS is in the mail and will be here monday

I plan on getting holes cut in the panel and getting it painted this weekend. My hoses and pump wont be here till monday as well But I should be able to get the large majority of the plumbing done this weekend and have it squared away thanksgiving weekend.

I plan on getting holes cut in the panel and getting it painted this weekend. My hoses and pump wont be here till monday as well But I should be able to get the large majority of the plumbing done this weekend and have it squared away thanksgiving weekend.

Nice. Keep us updated.

-BD

-BD

BTW... Why are you doing no sparge? You could do partial sparge by heating in your BK and gently pouring the sparge water on top of the mash water. It won't mix too much and will help rinse the grains. Alternatively you could batch sparge once. Or put sparge water into a separate vessel. Mine is two vessel also but i use the RIMs tube to heat sparge water on the fly. Although no sparge will make things much faster and only cost you a little bit more in grains so I am not sure why I am rambling on...

-BD

-BD

poptarts

Well-Known Member

BTW... Why are you doing no sparge? You could do partial sparge by heating in your BK and gently pouring the sparge water on top of the mash water. It won't mix too much and will help rinse the grains. Alternatively you could batch sparge once. Or put sparge water into a separate vessel. Mine is two vessel also but i use the RIMs tube to heat sparge water on the fly. Although no sparge will make things much faster and only cost you a little bit more in grains so I am not sure why I am rambling on...

-BD

Honestly because it seemed simpler than sparging. My current system I batch sparge. I wanted to give it a try just to keep the process simpler. If I decided I don't like the efficiency hit I will probably do as you are saying with heating it up in my BK or just do a cold water sparge.

I can dig it.

-BD

-BD

iijakii

Well-Known Member

Just paint it as a big hop.

Cool idea I had but your probably too late in the process to change it: Use plexiglass as your front cover and put some sort of cool colored light behind it so that it lights up the whole panel inside and out.

Similar threads

- Replies

- 11

- Views

- 968

- Replies

- 11

- Views

- 1K