- Joined

- Jul 12, 2017

- Messages

- 489

- Reaction score

- 422

After a second look I guess I don't see a lot of flaked grains but I still think you could be dealing with an over milled situation.

There are, But I’ve never had any issues at all. If anything I would probably just brew a batch with Pilsner instead of 2-row and see if that made a difference.Any other LHBS nearby? Brew a test batch using grains from a different shop, or from online.

I do have access to it, but I don’t store or mill my own grains. I simply buy them batch to batch. I suppose I could do this but I would probably just try another full batch using something other than the two row.Do you have access to six row malt? Do a couple stove top mini mashes. One with you current two row, one with the six row. Do you see a difference?

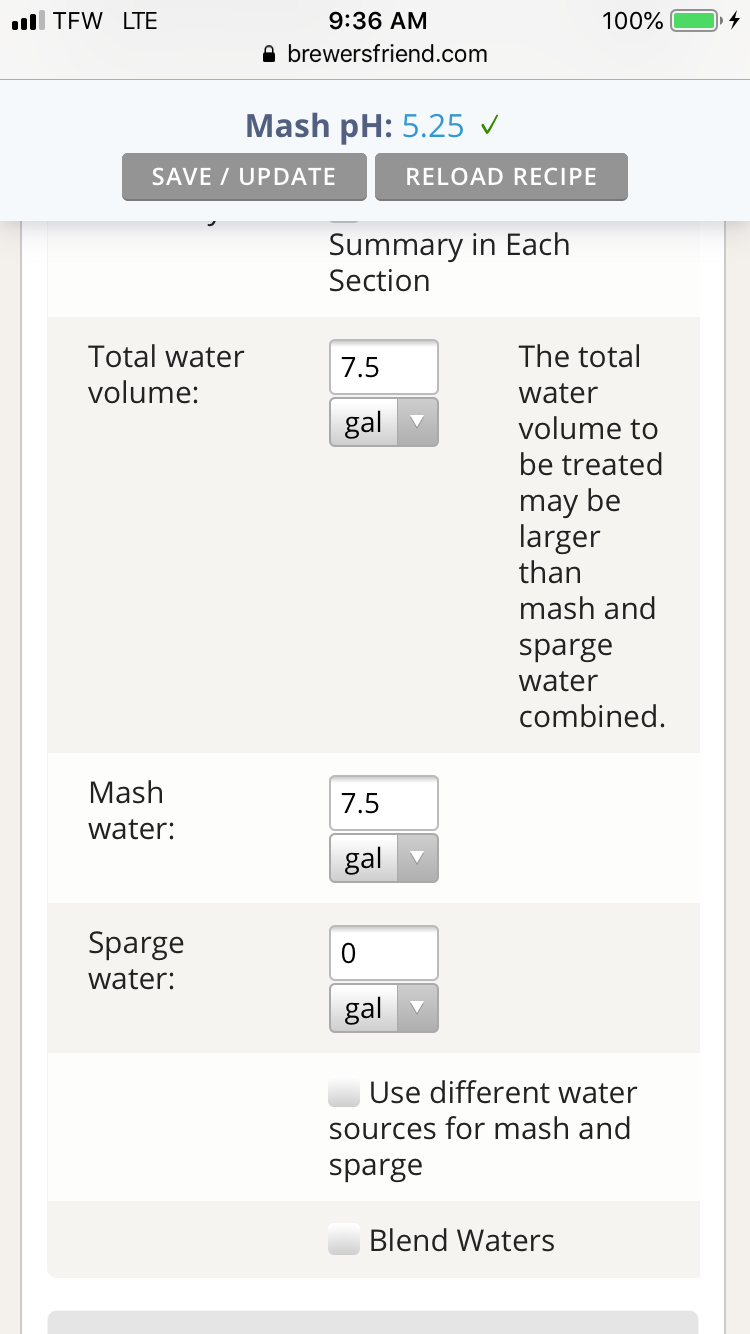

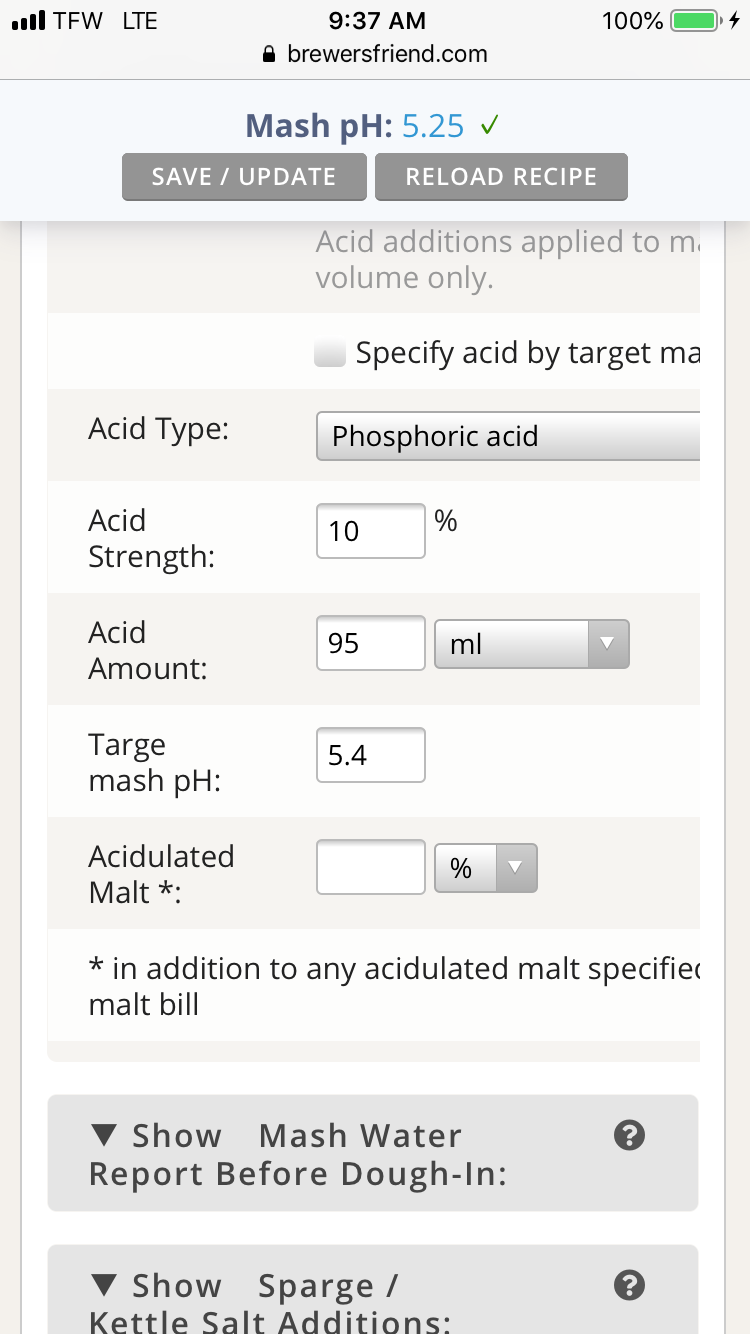

Here is a copy of my ward labs water report:Back to the water. I would double check your pH. Do you have a treatment system in the house like a softener? Regardless, you will probably want to add Campden to knock out any chlorine/chloramine and phosphoric or lactic acid to drop you pH to around 5.4-5.6. This will only help your mash enzymes to their job better.

I have been buying my grains from the same shop for several years. As I’ve said I don’t store my own grains, and I simply buy them batch to batch. At this particular store they have two options when buying your grains: Brew in a bag/extra fine, or traditional/false bottom. I have always ordered the brew in a bag crush option and never had these issues. I even spoke with the owner of the shop after the first time and the second time, and that was my initial guess was that maybe the grains were crushed more than they ever have been before. He assured me that nothing has changed in the mill setting, and it’s basically set as fine as it can go. So even if they wanted to crush them further they couldn’t.Do you mill your own grains? Hard to tell for sure from the picture as I see a lot of flaked grain but that gel can also come from fine dust of over milled grains. There is one homebrew shop near me that I've only used twice (4 beers worth) that way over mills their grain. Stuck sparges every time you buy from there which is the only times I have ever had a stuck sparge. The girl at the counter says I always use rice hulls no matter what, then laughs. Didn't put 2 and 2 together until the second time I bought from this place. It has been years since I let anyone mill my grains and this was the place that pushed me into milling my own grain. My normal home brew shop does a good job but buying in bulk saves money and milling is in my control now.

I kind of agree with you. It seems crazy that the grains may be void of the necessary enzymes, but I have to think that it is a possibility. I did a typical 60 minute mash like I always do, and yes I’m very certain of my temperatures. I use a digital ink bird and tested it yesterday in boiling water and it read 212 on the dot, and then put it under my tongue and it was exactly where it should be for my body temperature.I doubt it's a grain source issue. How long did you mash? And are you sure about your mash temps?

Looks like a lot of whole grains in your pictures.

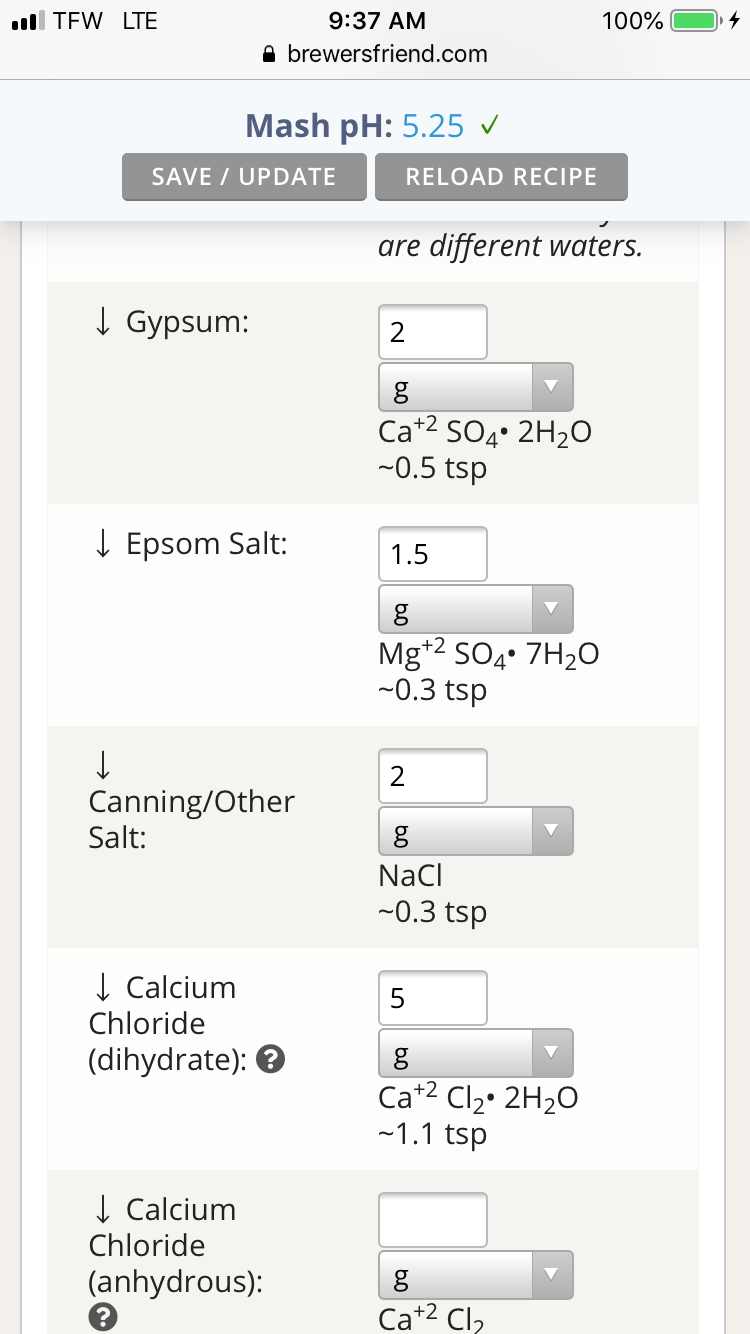

It’s definitely a possibility, but I keep coming back to the “it hasn’t been an issue before.” I’ve been using the same calculator for years and routinely put anywhere between 75-95 ml into my starting water.Just eyeballing your water and additions, that 95 ml of 10% Phosphoric Acid seems way too high.

Supposed to have been Briess 2-row. The same Briess 2-row I’ve used a million times before from the same shop. The more I go through all of the possibilities, the more I think there has to be something wrong with the grain.I too use a 5.25 mash pH for NEIPAs. If that acid addition worked before don't change a winning team.

What brand 2-row was that?

Could it have been [EDIT]chit malt?raw, unmalted barley?

It's possible they dumped a wrong sack in the 2-row bin, at your supplier.

I would definitely try to check that before brewing another batch.

As I said before, do a small 8-16 oz test mash with that "2-row" in a small pot in a 155F warmed up then turned off oven. Check for conversion.

Oh, definitely!The more I go through all of the possibilities, the more I think there has to be something wrong with the grain.

Thank you for chiming in. I just ordered another test kit from ward labs. I’m definitely interested to see if the water has changed and will report back once I get the results. Should prob be about 7-10 days or so.I guess it's a good time to chime in as I'm the grain vendor. First, I agree that based on the wet grain picture that it's extremely starchy looking so I'm positive it's a conversion issue. My first thought was temperature but that was already fully discussed. I see the 212 in boiling water test but would also recommend an icewater slurry test to make sure the calibration is linear.

Grain source: First, we do not buy or stock unmalted barley but I wouldn't rule out Briess putting unmalted barley in a standard Brewer's Malt bag. However, We buy our Briess 2row from primarily LD carlson and BSG and I buy 20-30 sacks at a time. Both of the OP's batches came out of the last 3 sacks we had in the lot because I'm down to about 10 pound from being out right now. If there was a problem with that lot of malt, there would have been about 850 pounds of it used previously and I would have heard about it. Actually two of my employees just recently brewed with the 2-row as well.

One thing that I do every brew day is take in-progress samples from the mash and test the gravity. I like to see the gravity rising and compare that against the elapsed time to see if I think I'm hitting my numbers or not. If I had a mash that wasn't converting, I'd see that right away as I'd be way off the numbers.

I'm performing a small mash right now with one pound of the malt and will report back in an hour.

Water... It's possible the profile has changed quite a bit which is why I stopped using tap water over the years. I'd send a sample to Ward a few times a year and see it waver in a way I wasn't comfortable with. $100 later I have an RO system and build from zero each time. It's worth trying a batch with RO or distilled to see.

The pH of the tap water means nothing (or very little). It's the alkalinity and dissolved minerals that drive the pH, and more so, the resistance to change the pH.Tap water PH of 6.5: mash PH unaffected

Tap water PH of 7: mash PH unaffected

Tap water PH of 7.5 (what I had initially inputted and am currently under the impression it is) 5.25

Tap water PH of 8: mash PH of 5.26

Tap water PH of 8.5: mash PH of 5.26

So even if the new water report comes back different, will it really make that much of a difference to completely screw up the mash’s ability to convert?

It’s certainly an option. As I’ve said repeatedly though this is never been an issue before and I’ve brewed a lot of beer. The make up of my tapwater from the original ward labs report I got is actually really really good. Definitely looking forward to seeing what the next report says.If your water content fluctuates much or makes it totally useless for brewing at times, but unknown to you, do what @Bobby_M did, get yourself a small RO system, for around $100. That would be my choice and preference.

Russ from @Buckeye_Hydro is a forum sponsor, he can set you up.

Ding Ding Ding! We have a winner. The last two batches in question both used that bottle that I purchased with the first bag of grains. I ran out of my previous bottle and purchased a new one and it has only been used on these two batches. I personally do not measure my pH… I simply trust the calculations because they’ve always been accurate enough, and like I said I’ve never had any problems. It’s 100% the phosphoric acid.Not at all. I'm not in full defensive position as I'm just as interested in figuring it out as you are. Mash test result was good. 1.055 OG with 1 pound in 2 liters of water.

Here's a very key question. Did you measure your mash pH with 90mL of phosphoric added or did you trust it based on previous calculations/results?

The reason I ask is that I just received a phone call (I mean literally as I typed the first sentence above) from LD Carlson telling me that I should discard the bottles of phosphoric that I got on my last order because it had a higher concentration than 10% as labelled. I didn't think to ask them what the actual concentration was and then I keep getting their voice mailbox. Low and behold, I looked it up and you got one of those bottles from me. I will find out what the concentration actually is but you probably had a mash pH of 1 or something goofy like that. 90mL even at 20% (double) your mash would have been 4.49. I know phosphoric is available in 75 and even 85% concentrations and if that's the case, the pH would be REALLY low.

I'm going to make LD replace the phosphoric and grains. I'll get your last two orders credited right away.

Ouch!!!I just received a phone call (I mean literally as I typed the first sentence above) from LD Carlson telling me that I should discard the bottles of phosphoric that I got on my last order because it had a higher concentration than 10% as labelled. [...]

I really doubt that. I mill my grains finer in my BIAB. I never have anything near to what he describedAfter a second look I guess I don't see a lot of flaked grains but I still think you could be dealing with an over milled situation.

If it is the overly concentrated phosphoric acid, it would be interesting to know what the mash pH actually was. This would give us a data point about what pH level will almost completely shut down conversion.