BadNewsBrewery

Well-Known Member

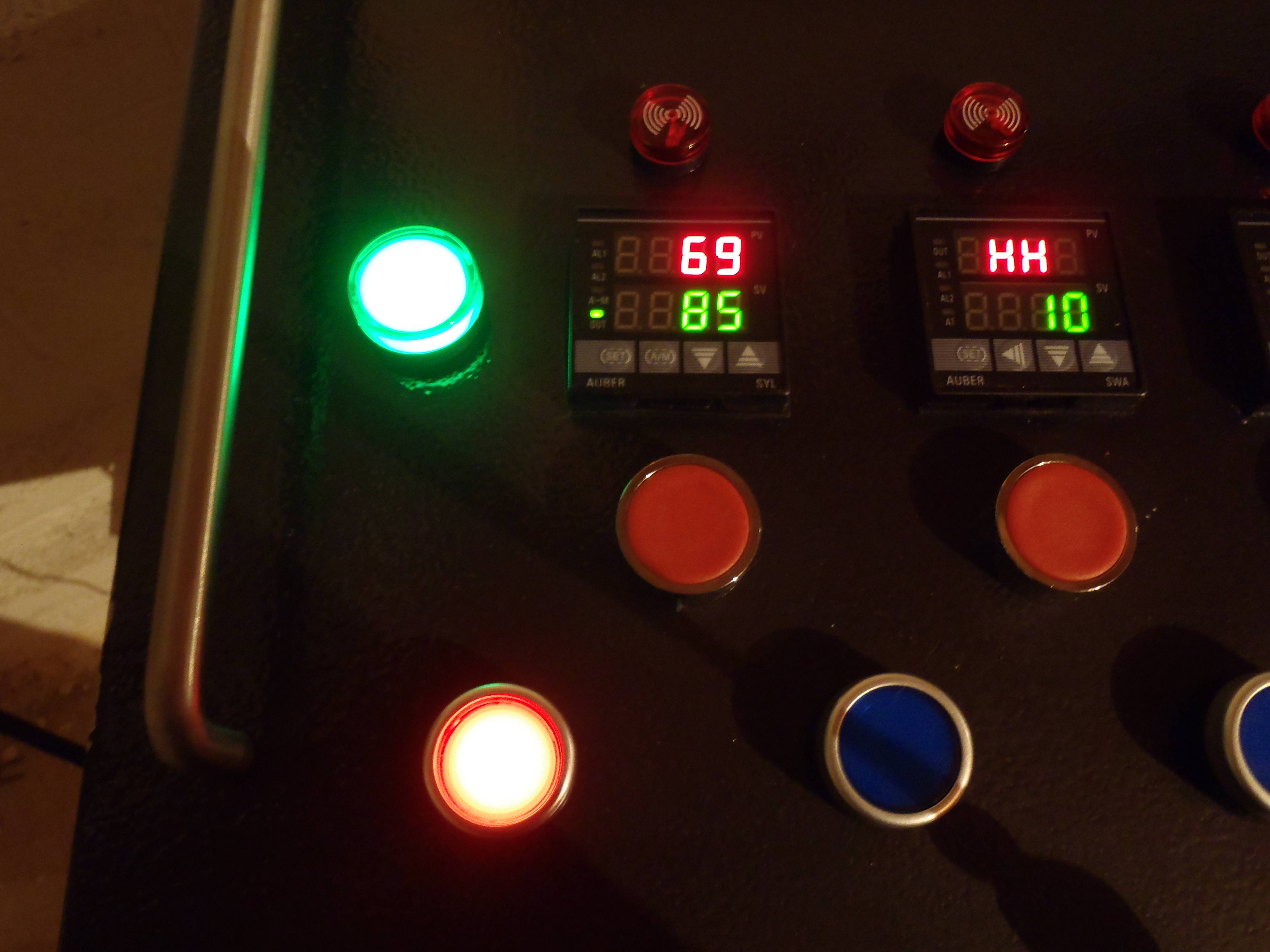

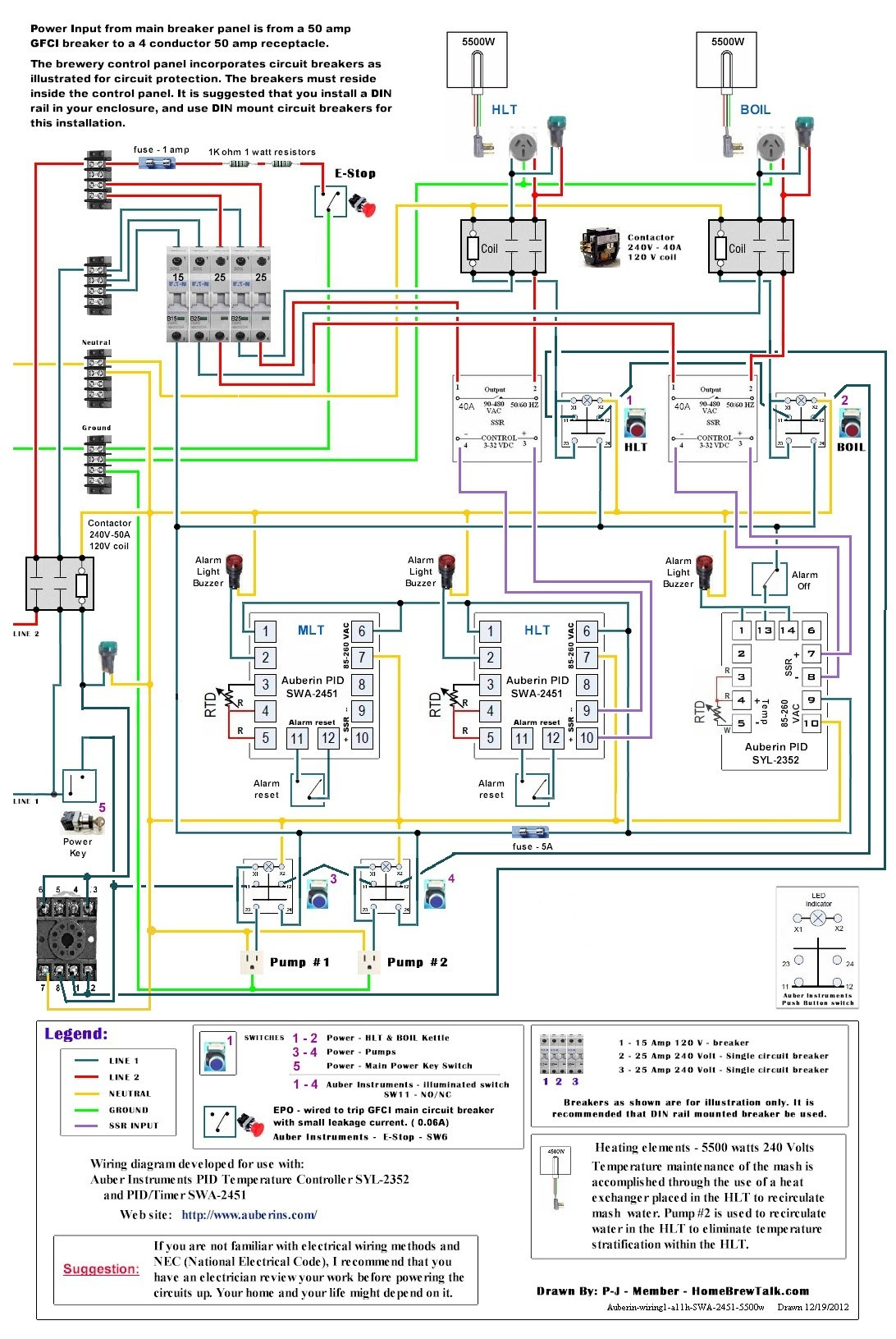

Alright - I got the switches working. I had run them at 240v, with Hot A to X1 and Hot B to X2 through the NO portion of the switch. So, with the contactor 'leaking' neutral, I wound up getting 120V from X1 to X2. So I changed the feed to X1 to neutral and now the lights only come on with the switch depressed.

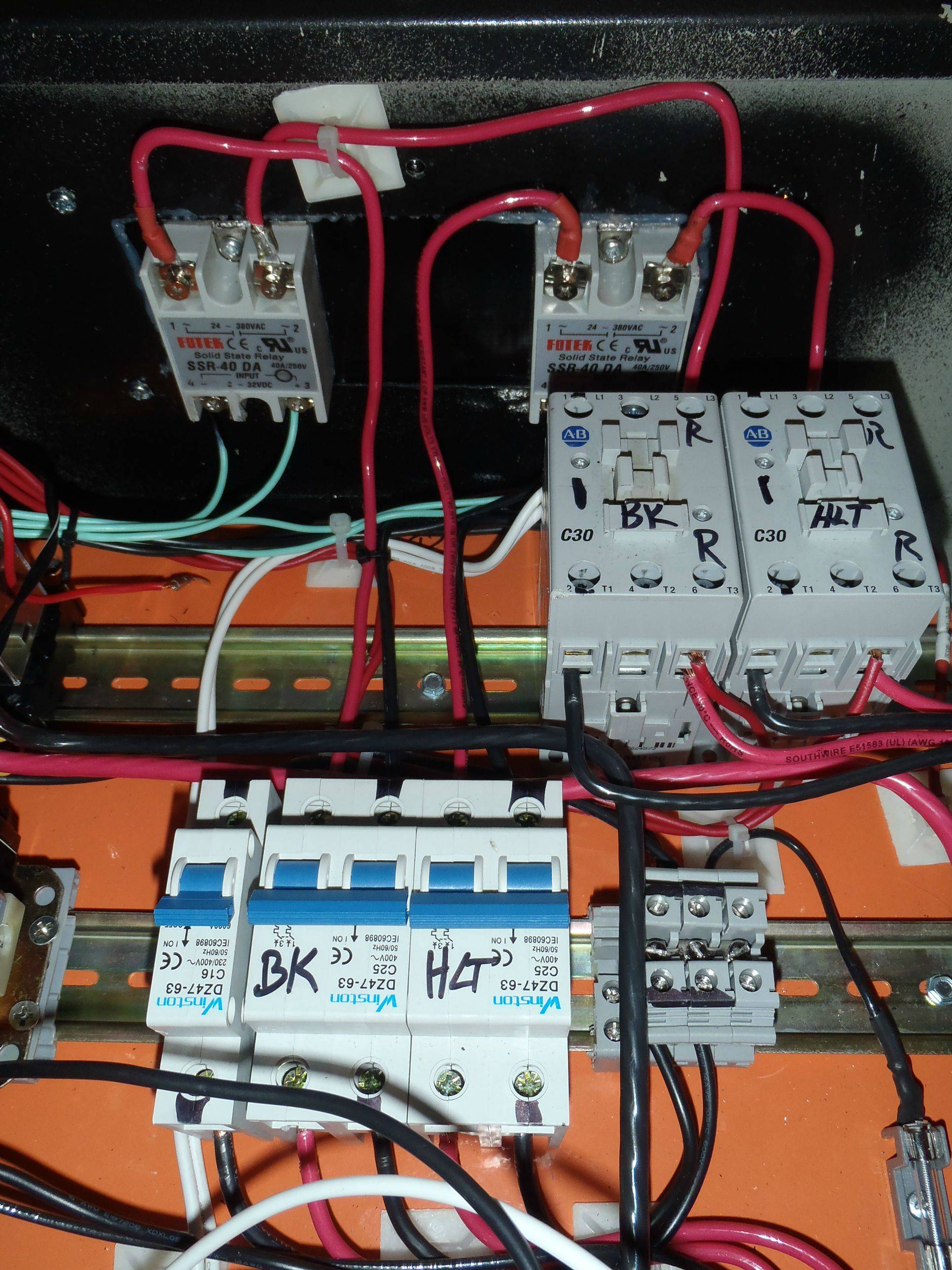

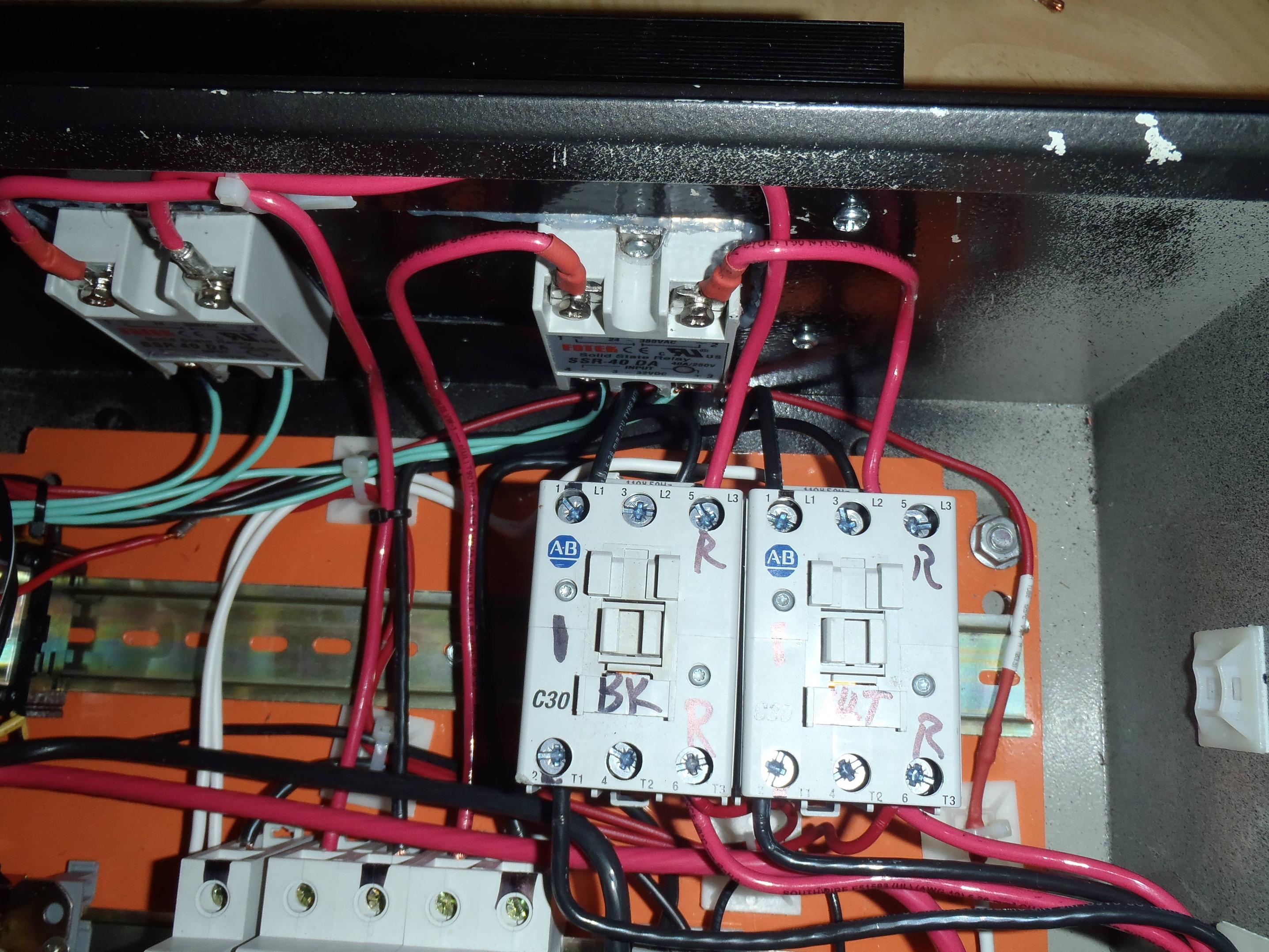

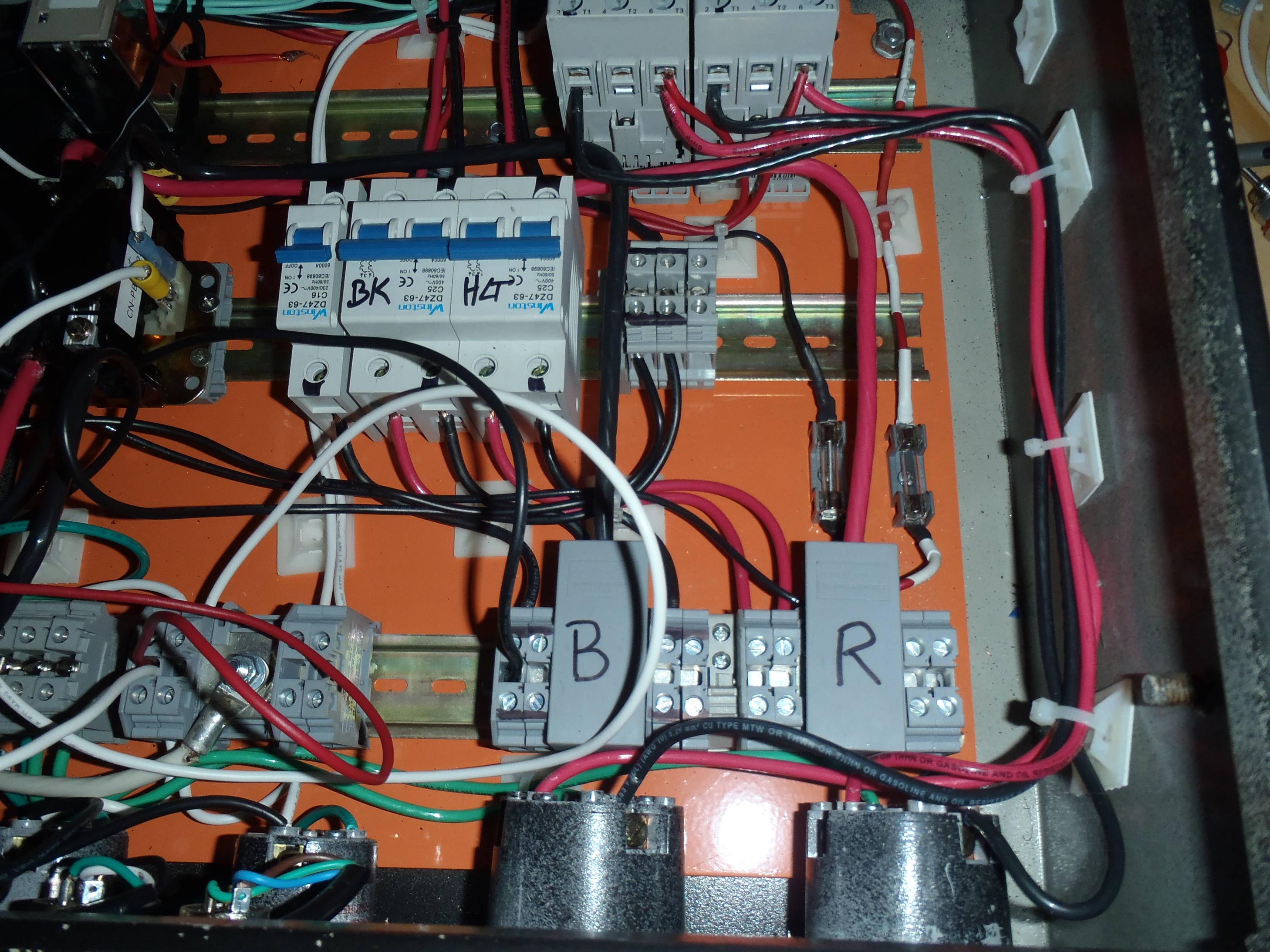

New problem though... the element LEDs come on when the element contactors are turned on, regardless of what the SSR is doing. I run power to the light from the red and black lines downstream of the contactor, just like in my wiring diagram. In theory, the SSR limits the juice flowing to the red line, so it should only turn the LED on when the SSR is switched on.

I took some readings to see if I could figure out what was wrong. All measurements taken from the downstream contactor red line to either the white (neutral), black (Hot), and Red (should be zero... red to red...) Here they are:

SSR off / Contactor Open (off) - 115 (W) / 2 (B) / 240 (R)

SSR off / Contactor Closed - 66 (W) / 54 (B) / 185 (R)

SSR on / Contactor Open - 115 (W) / 2 (B) / 240 (R)

SSR on / Contactor Closed - 120 (W) / 240 (B) / 2 (R)

So, in condition 1, it looks like the red line coming off the contactor is acting like a Black line to cause a reading of 240.

Condition 2 - no clue where those numbers are coming from. SSR leakage?

Condition 3 - Black again

Condition 4 - Red - the only time it's actually right.

What the hell is going on here?!

New problem though... the element LEDs come on when the element contactors are turned on, regardless of what the SSR is doing. I run power to the light from the red and black lines downstream of the contactor, just like in my wiring diagram. In theory, the SSR limits the juice flowing to the red line, so it should only turn the LED on when the SSR is switched on.

I took some readings to see if I could figure out what was wrong. All measurements taken from the downstream contactor red line to either the white (neutral), black (Hot), and Red (should be zero... red to red...) Here they are:

SSR off / Contactor Open (off) - 115 (W) / 2 (B) / 240 (R)

SSR off / Contactor Closed - 66 (W) / 54 (B) / 185 (R)

SSR on / Contactor Open - 115 (W) / 2 (B) / 240 (R)

SSR on / Contactor Closed - 120 (W) / 240 (B) / 2 (R)

So, in condition 1, it looks like the red line coming off the contactor is acting like a Black line to cause a reading of 240.

Condition 2 - no clue where those numbers are coming from. SSR leakage?

Condition 3 - Black again

Condition 4 - Red - the only time it's actually right.

What the hell is going on here?!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)