OneManBrewery

Well-Known Member

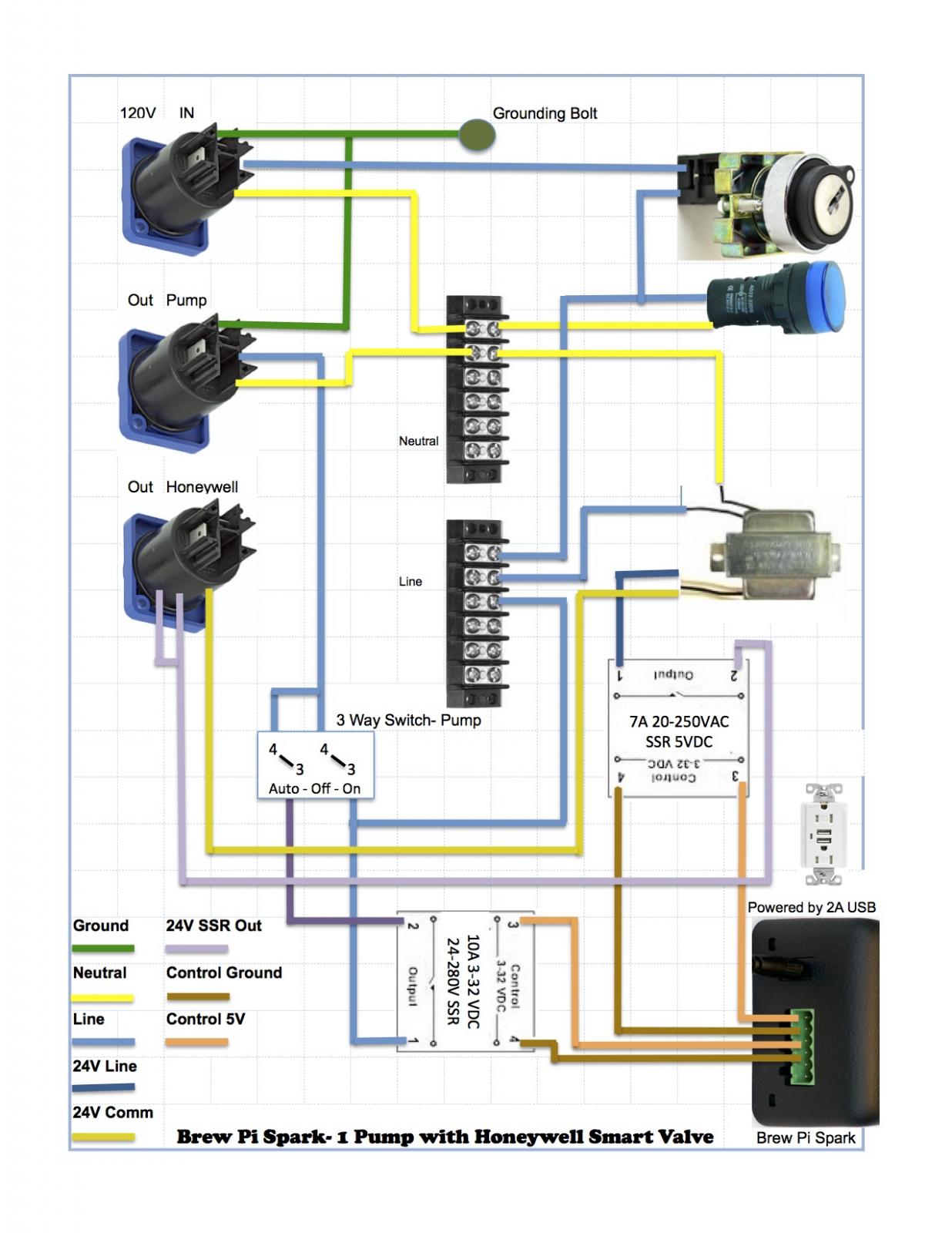

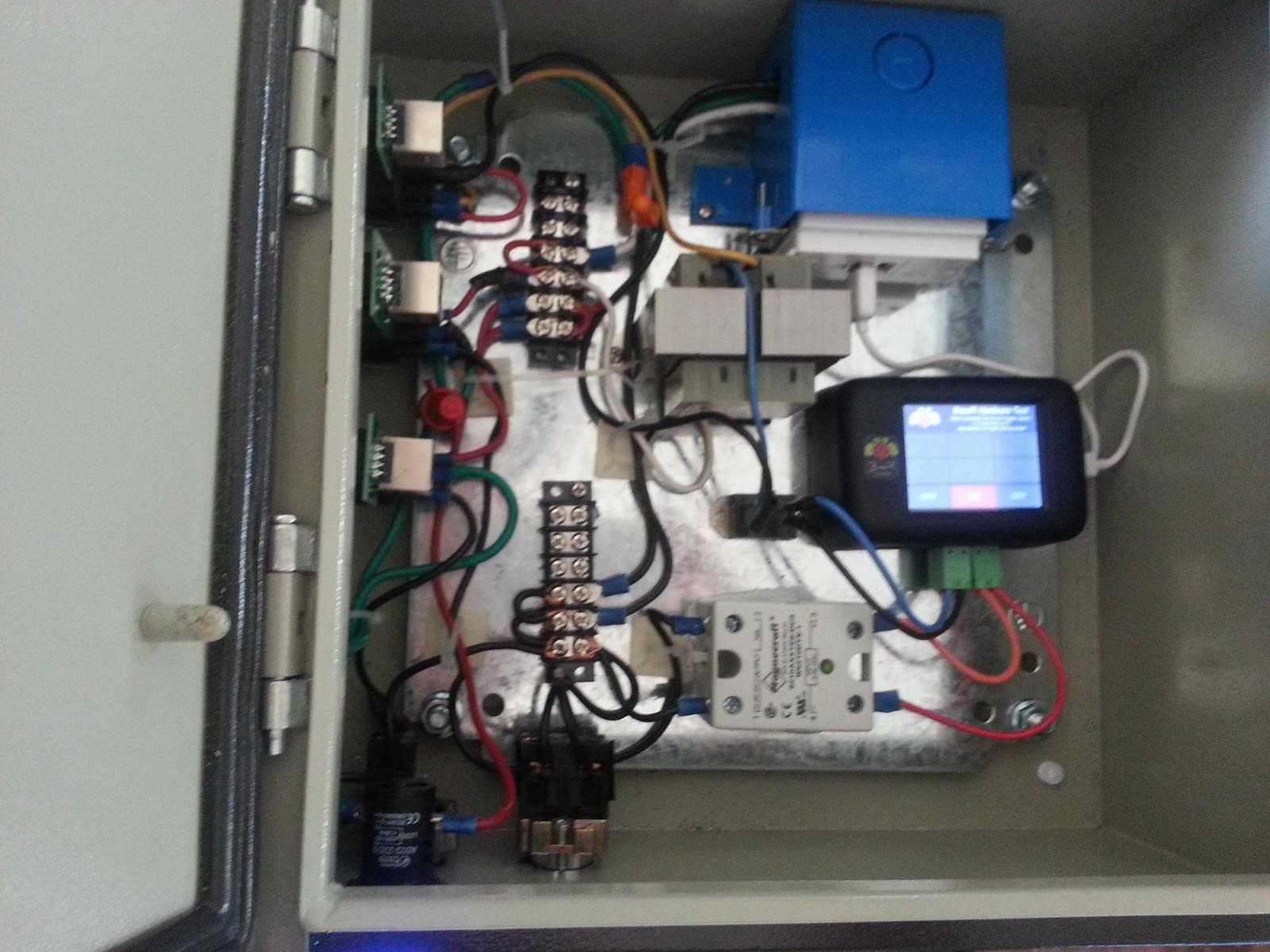

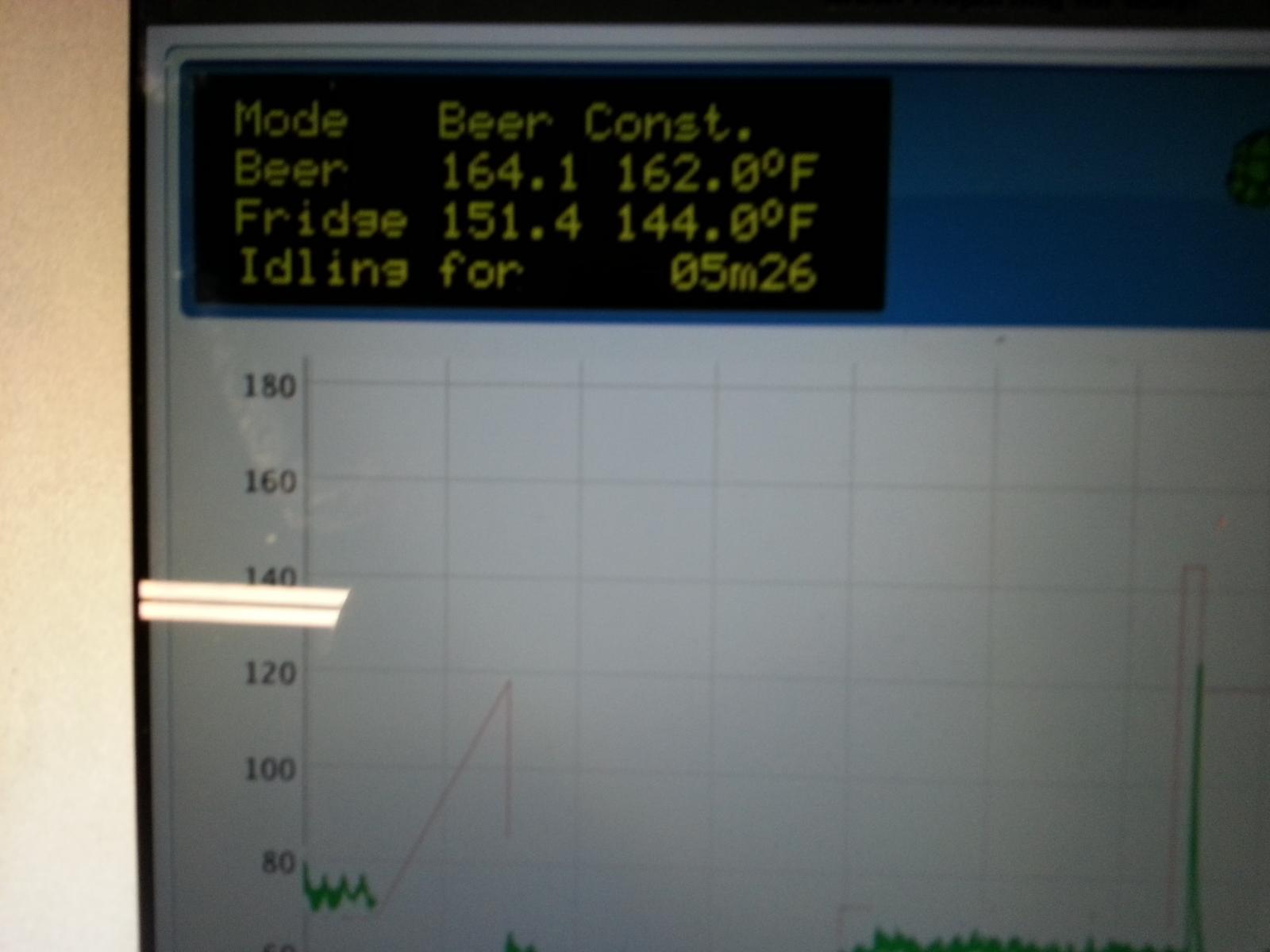

My New Years Resolution is to bring my 3 Tier stand into the future. I'm upgrading from a Rubbermaid cooler to a HERMS. I haven't decided on my controller yet, but I know I want more then just 2 Temp Controllers. I've done some research on the BCS-460 and JonW's build with it is inspirational. Then I found the Elco's BrewPi Spark which didn't help things but it's still in production with limited info ... so I'm stuck. Anybody have any suggestions?

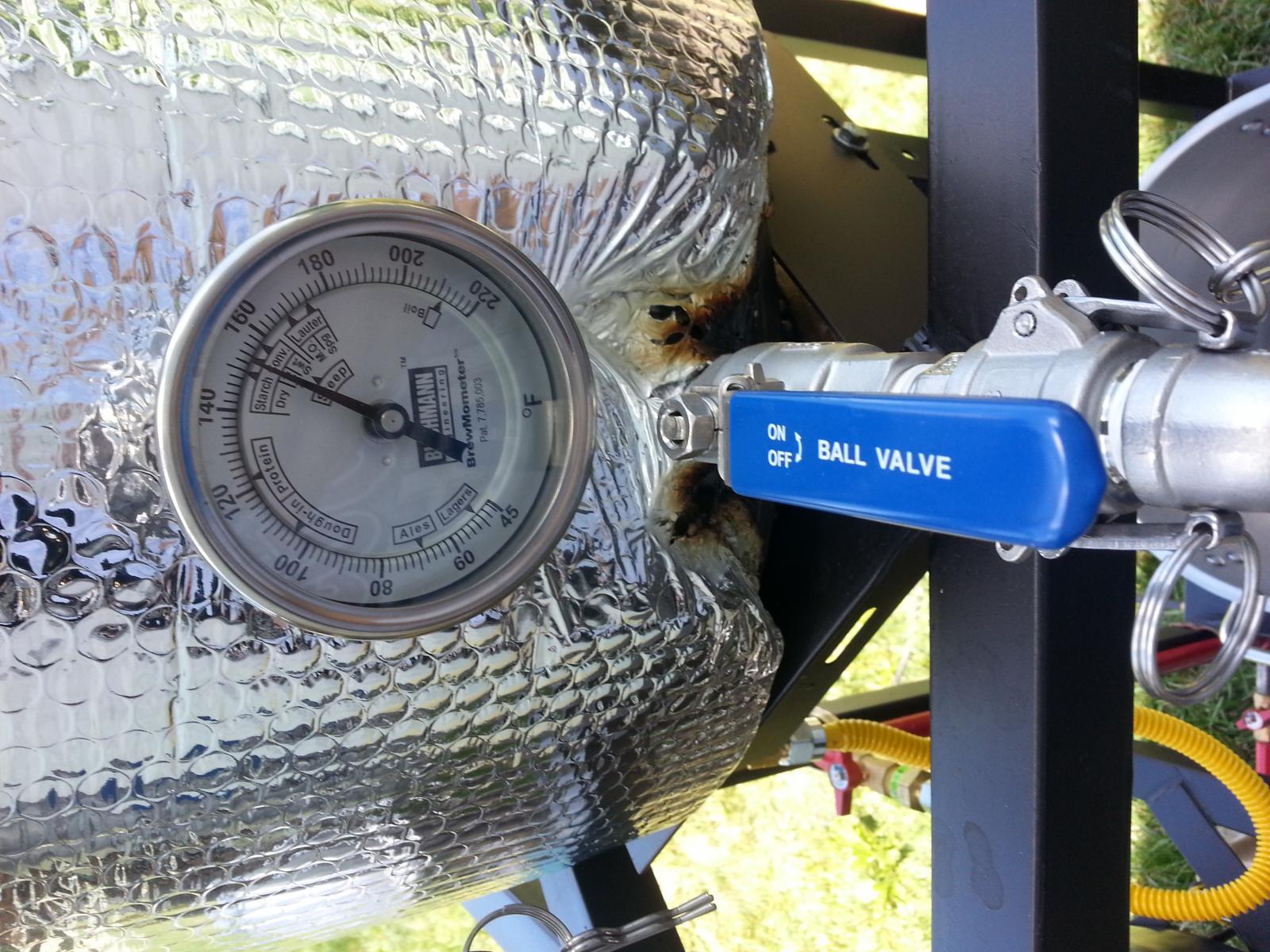

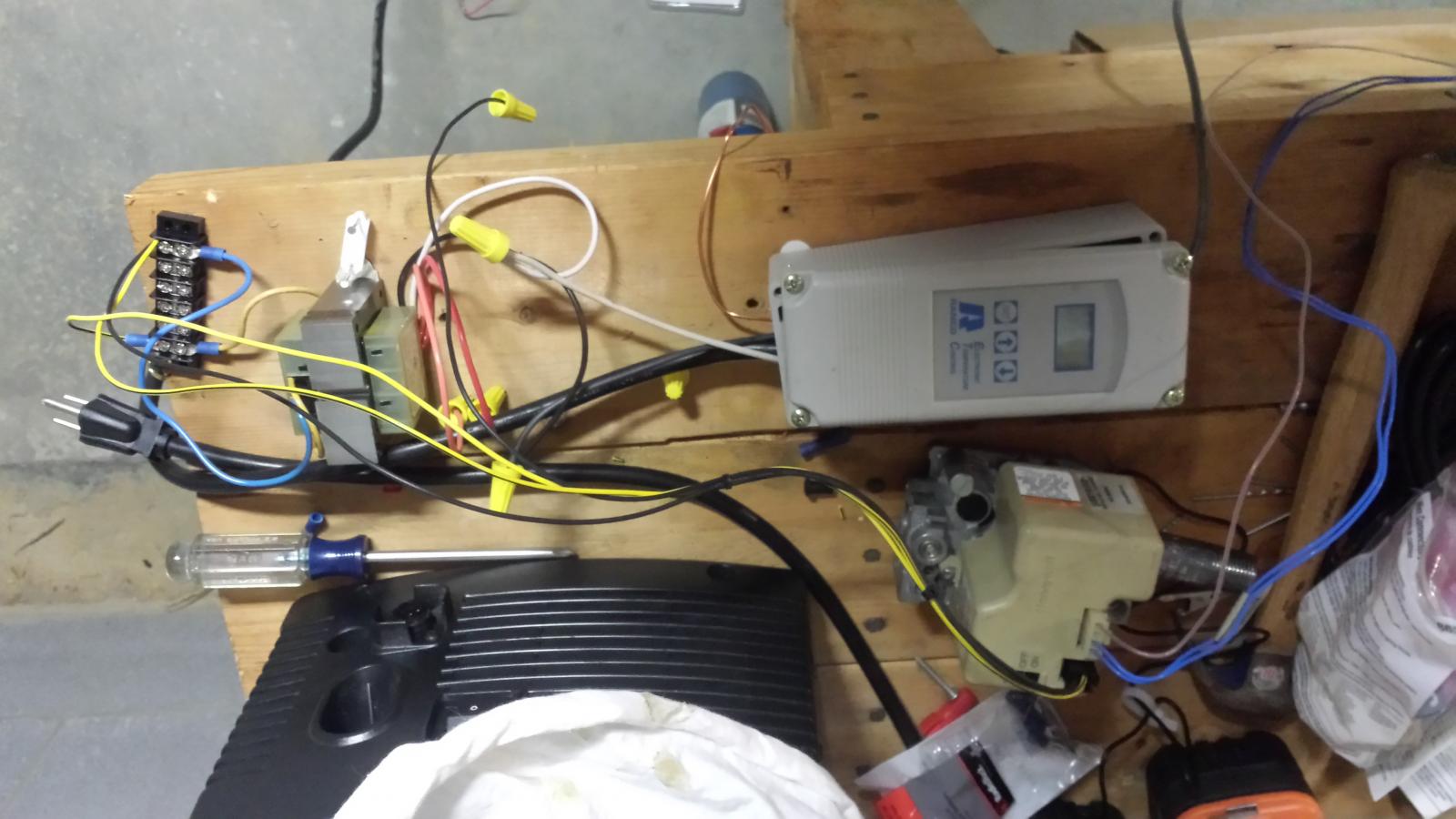

As for the rest of my build, I've started this Fall by adding a Honeywell Smart Valve with Pilot Burner to my propane system which works exceptionally well for those looking for a valve. The picture below is me trying it out with my Ranco from my Keezer before installing it.

I have a pump on the way from Brew Hardware with their genius add-a-pump kit. And the fittings for my HLT Keggle build. Happy 2015 everybody.

As for the rest of my build, I've started this Fall by adding a Honeywell Smart Valve with Pilot Burner to my propane system which works exceptionally well for those looking for a valve. The picture below is me trying it out with my Ranco from my Keezer before installing it.

I have a pump on the way from Brew Hardware with their genius add-a-pump kit. And the fittings for my HLT Keggle build. Happy 2015 everybody.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)