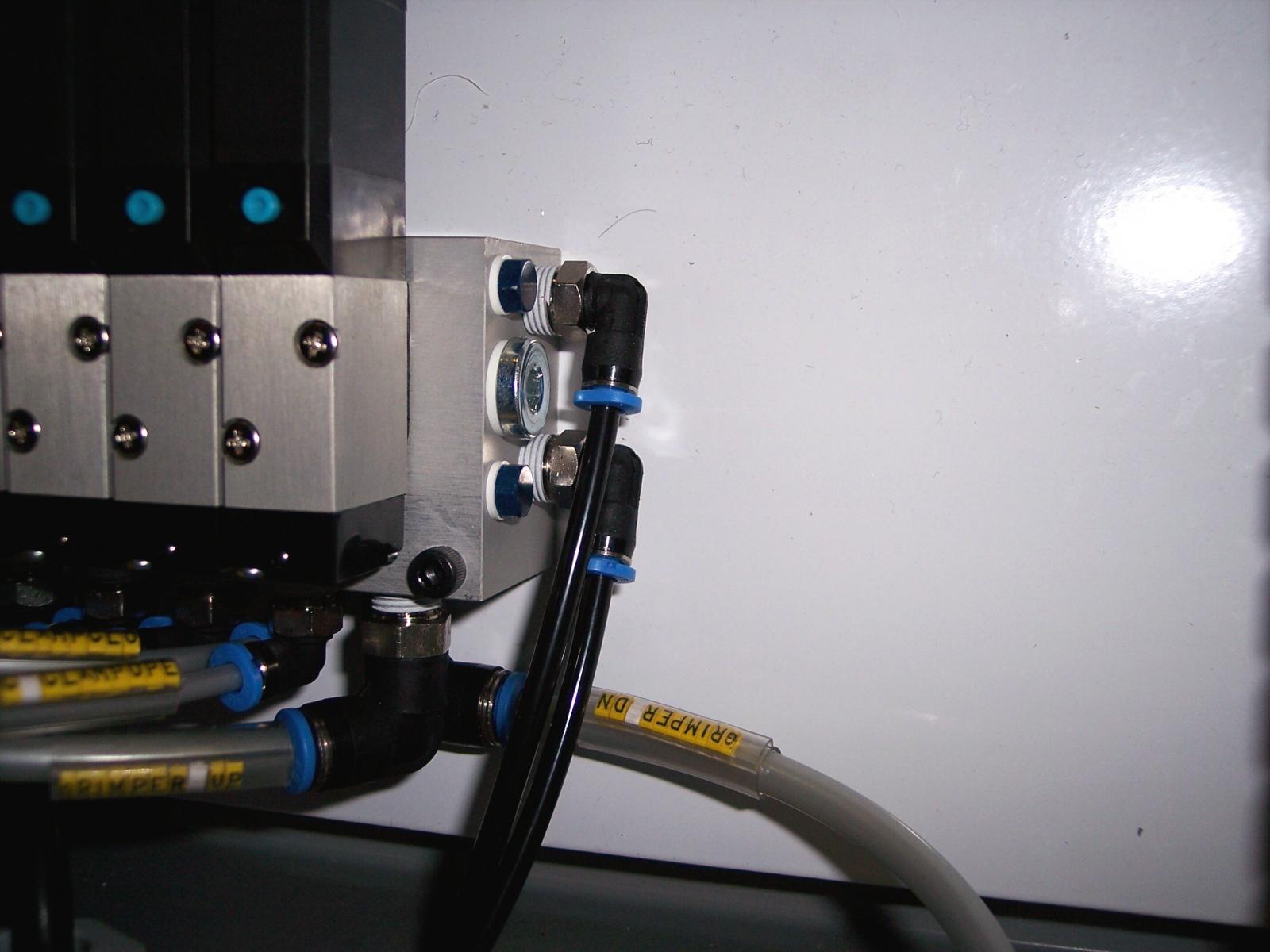

If you'd really like to remove disassembly from your cleaning process, you should consider using sanitary diaphragm valves. GEMU is one brand that makes them. They are commonplace in the biopharmaceutical industry (which is quite similar to brewing), and many high end commercial breweries. The problem is: price. Brand new they can range from $200-2000 depending on size and options. You also do need some infrastructure to manage them, namely an air compressor, electrical poppet valves to actuate them, and switches/processor to manage the actuation. However, for a true clean in place system, they are the best, hands down. They also actuate very quickly.

You can find them on eBay for pretty cheap, I've bought 20 or so of them in the last year for under 50 each (some as low as $6-10). They usually come equipped with tri-clamps already, no threads. Here's an example of a 3/4" 4-way

HERE.

My system uses a bunch of them, you can see one disconnected from it's base [ame=https://www.youtube.com/watch?v=n5DhliV6Fso]HERE.[/ame]

And here's the whirlpool/fermentor transfer [ame=https://www.youtube.com/watch?v=7OSIQXEByeo]HERE.[/ame]

I'm not trying to dissuade you from using ball valves, but you must consider disassembly of the valves into your brew day to get them completely clean. In reality, it all comes down to how much time you're willing to invest; it took me a long time to weld/fit everything together (9 months of fabrication), but that early investment takes a lot of time and stress out of my brew day...

Cheers!

Matt Kosonen

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)