After brewing for the first time this Saturday on our brew system we are happy to report success! Their were a number of issues we ran into but lets talk about what went right first.

One of the most surprising things was that the burners worked so well. They heated ~5 gal in the kettle and ~10 gal in the HLT fairly quickly. The keggles also maintained temperature very well during mashing. We simply fired the burner under the HLT and kept recirculating using one of the pumps to maintain mash temp indirectly. Computer automatin will really help things here.

We used a spare piece of 1/2" silicon tubing that we pushed inside a 1/2" coupler to use as a sparge arm. We are awaiting a special 1/2" MPT to barbed adaptor to better couple the tubing to the coupler but just pushing it inside the female threads worked fine for this batch.

The most important part though was that we were able to extract sugars from the grain! This was not only our first time brewing on our new system but also our first time brewing with all grain!

Now onto the bad news... what went wrong...

Throughout most of the brewing process our system uses 1 pump, with the excepting of some dual recirculation, and most importantly, sparge out where we go A->B->C at the same time. It was right before this critical use of both pumps that one of the SSR's decided to fail and we had to manually plug/unplug the pump in order to control sparging flow. This is making me seriously consider segway style dual redundancy for everything...

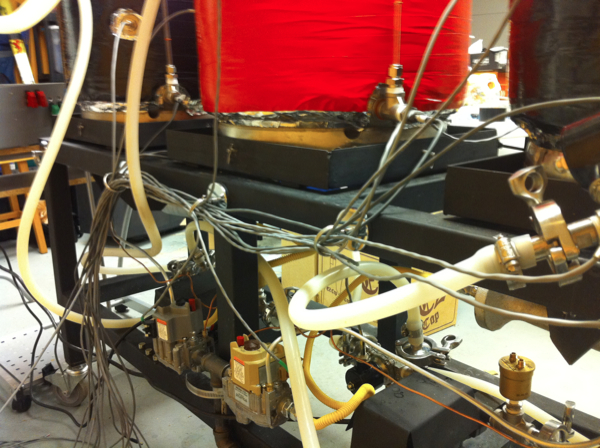

We have 10x 12vDC 1/2" solonid valves in our system. Some of them get super hot, while others do not. One got so hot we had to stop using it, it was on for less than 5 minutes. No shorts or other wiring issues were found. Strange, but we need to look into why some are almost 200F while others are cool, with no liquids inside.

Wires for the solonid valves were another issue, we hand made cables with a mono 1/8" headphone jack on one side and a barrel power plug on the other. This was so that the cable could carry the necessary current to power the valves without melting, as audio cable is not rated for this kind of thing. We neglected to take into account how hot the frame would get and we melted two of the wires. We definitely need to both protect and better route the wires.

Our temperature probes were useless in some cases. We were brewing a 5 gal batch instead of 10 for our first test batch. This means that the temp probes placed at the half way point on the kegs were useless when they were 1/3 full with 5 gal. It looks like we will be getting sight glasses with temp probe slots and adding additional probes to all 3 kegs.

We definitely over sparged. Our initial brix reading was 5, and we were shooting for 13.5. So not sure if it was purly over sparging (due to pump issues etc) sparge rate of flow was too fast, too much additional sparge water from the HLT, etc but we had to add ~3LB of DME to bring up the reading to 15 which then settled out at 14.5 when we finished the boil.

All in all it was going really well considering a few minor technical glitches and in experience, we had 5 gal of wort in the kettle and were boiling away. Just when we thought we were home free, disaster struck.

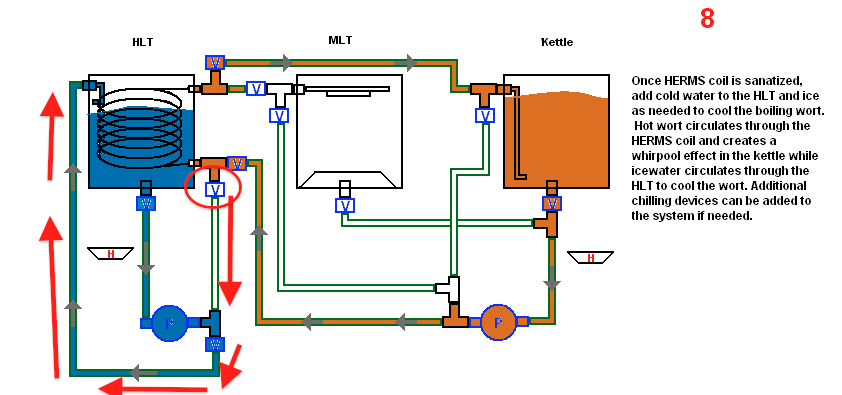

We were in the whirpool stage of our brewing where we recirculate the boiling wort through the HERMS coil while nothing is in the HLT and then add ice and water, and recirculate that at the same time to cool the wort. We had just tightened everything down in the coil previously so their would be no cross contamination. Their was a bit of left over wort in the pump lines in the HLT from a previous step, which didnt matter as it was recirculating over the ice and not the wort. So when we saw some foam and beer colored water enter the HLT return we didnt think anything of it, it was coming out COLD.

When we removed the lid on the kettle and saw a few gallons missing, and opened the HLT lid and saw a huge mound of foam, we knew something was wrong. At that point we shut everything down and dumped what we had in the kettle into our 3gal kettle and brought it inside to cool it in the sink as we have done for the past 4 years. We were able to save about 3 gallons of the wort, but lost about 2 into the HLT. After cleaning and testing again we figured out what was going wrong.

The red arrows in the picture show the path of *some* of the wort during cooling. It would appear that the indicated valve that was OFF let *some* of the wort through it, mixing with the 35F water causing cold, mostly water, wort to enter the HLT.

All of the valves are one way as indicated by a -> on one side. We had a few problems with other valves that were put in backwards and they weren't flowing. In this case the valve is in the correct way. During testing afterwards, we put 5 gal into the kettle and recirculated through the HLT coil with nothing in the HLT. The pressure was enough that it was entering the distribution section connected to the outlet of pump 1 and the path of least resistance was to enter the HLT return. Clearly we have a defective valve or we need to reconfigure something. We may be able to fix this simply by swapping this valves location with another valve, like the one in front of the HLT.

So now, our 3 gallons of beer is happily fermenting away in its new fermentation chamber. We are very happy our system worked overall and we were able to produce beer with it. Though their are a few problems with the system at the moment, we believe we can fix all of them and be ready for the next batch.

If anyone has some suggestions or questions on what we did or what we are going to do in the future let us know. Also, the entire session was filmed on a 7D so after that is edited it will be up here.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)