That article only encouraged me to carry on with my post-fermentation head space management strategy, overkill though it might seem to some.

I've been applying very light CO2 pressure once FG has been achieved rather than leaving a blow-off or S-lock in place. If I'm dry hopping (which is pretty much everything aside from my imperial stout) I'll remove the carboy cap, dump in the hops, reinstall the cap and let it come back up to pressure.

I used to dial down one of my standard CO2 regs but it was a pita to get it low enough but not "off", and there were upwards drifts on more than one occasion (the balloons totally worked

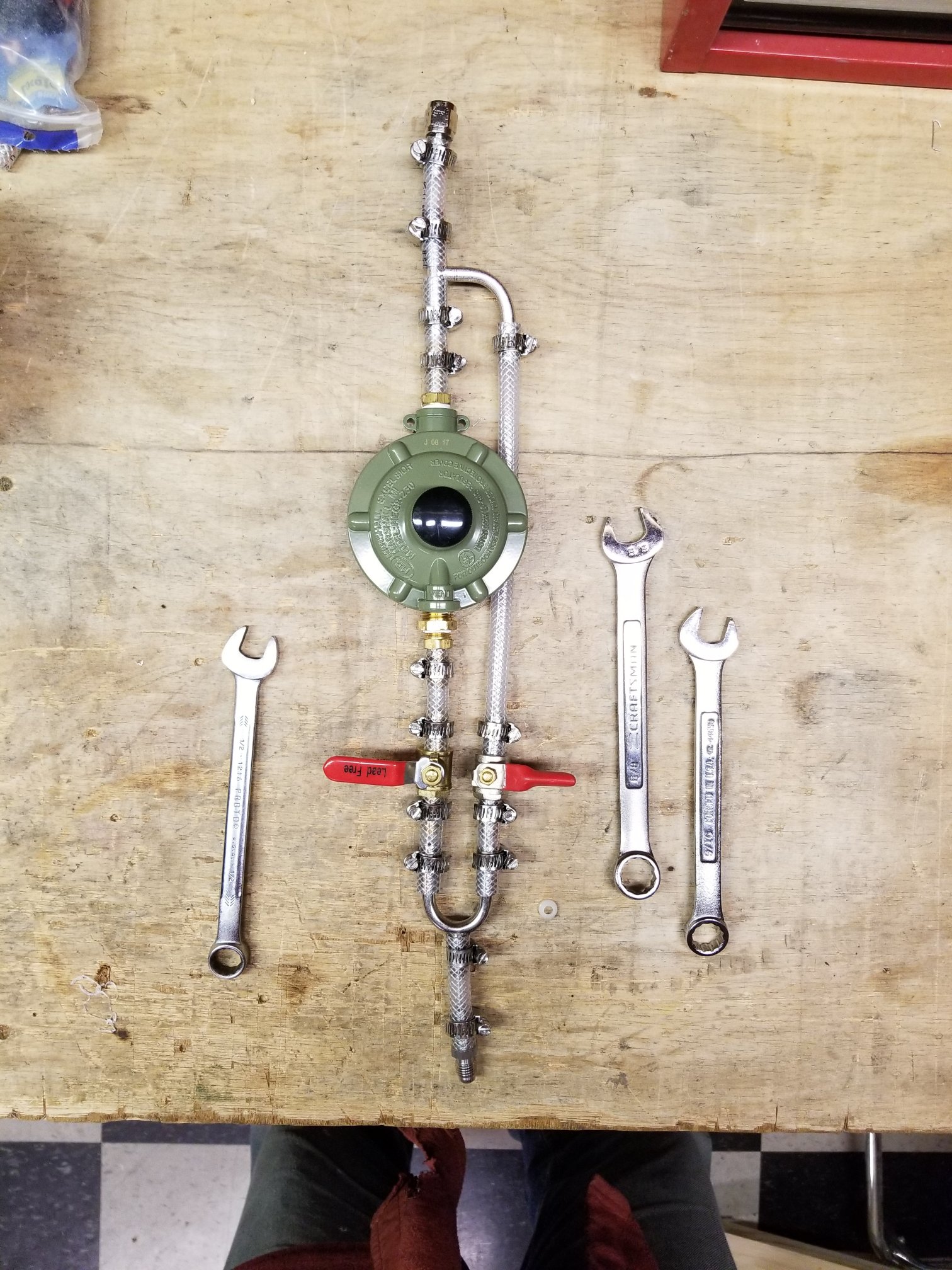

). So I picked up a Marshall dual-stage 11" wc (~ .4psi) fixed regulator - the same reg that low pressure gas brew rigs favor - that works as a "secondary" and is uber reliable at maintaining that low pressure.

Of course I couldn't just hook it up when I needed it, I wanted to be able to switch it in and out instead, as there are times I use that fridge for carbonating kegs when the other fridge has fermentors or is filled with other kegs. And as the reg has a vent on the down-stream end I needed a pair of valves to do that. Looks like a leak-fest waiting to happen, right?

Well, I taped over the vent, capped the output fitting and hooked gas up to the input end and dunked the whole works. No leaks. Onwards!

All hooked up, works great. I used it on the last three batches with the same pair of balloons.

It's not spunding, and the CO2 is whatever purity my lhbs carries, so there's still some risk of oxygen getting into the carboy, but the math suggests it's magnitudes lower than exposure to the atmosphere through a liquid interface...

Cheers! ("Things You Probably Don't Need Department"

)

). So I picked up a Marshall dual-stage 11" wc (~ .4psi) fixed regulator - the same reg that low pressure gas brew rigs favor - that works as a "secondary" and is uber reliable at maintaining that low pressure.

). So I picked up a Marshall dual-stage 11" wc (~ .4psi) fixed regulator - the same reg that low pressure gas brew rigs favor - that works as a "secondary" and is uber reliable at maintaining that low pressure.