Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I went from 3 carboys to the cf15. It's WAY easier in every aspect. CheersI like the question OP.

Lately I'm in a funk with multiple aspects of kegging. I believe I've got a slow leak in my system and wasted 2 bottles of gas. Still not sure where it is but I suspect I need to replace some of my poppets.

When closed transfers go well they add about 90 minutes to my packaging exercise. This comes from the time to purge 3 kegs using the push the star san method followed by the slow filling from the fermentor into those same kegs.

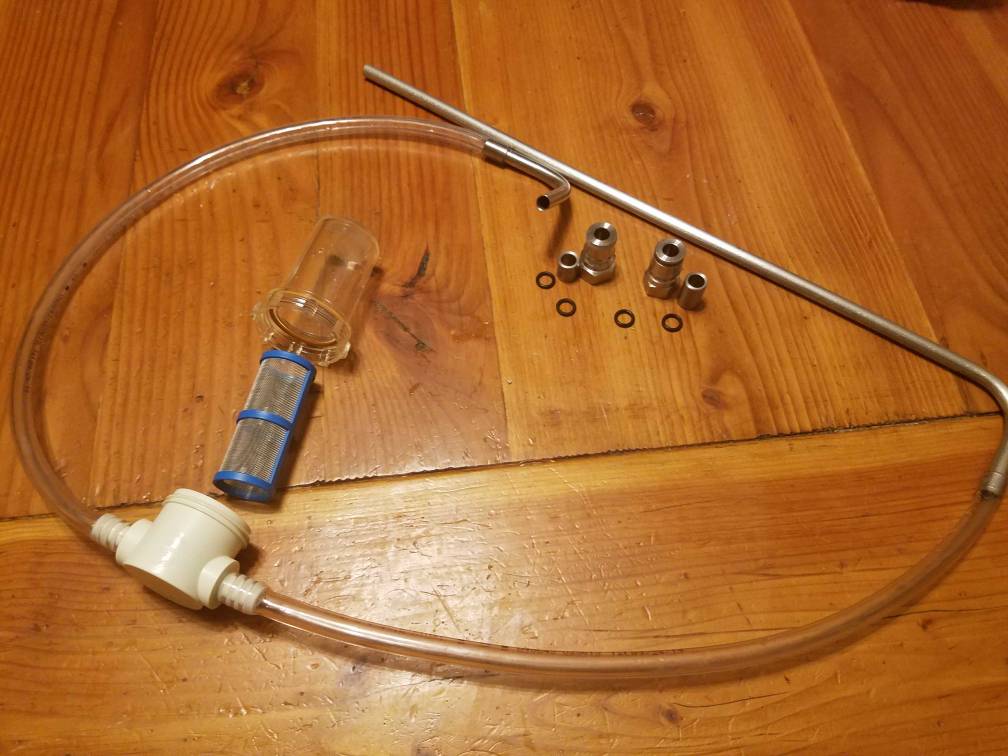

I have a plastic Speidel fermentor sitting in a fridge about 18" off the ground. It is too heavy to lift when full so gravity draining is not an option. I have a large ss dip tube and 1/2 ball valve on the fermentor and a gas post on the lid. I can pressurize it to about 2-3 PSI without blowing the lid. Best of days filling those 3 kegs is very slow.

Most of the time however they simply will not fill. The poppets quickly plug and your closed transfer is over. I have done the thing with taking out the poppet from the post and the plunger from the connector and that works. But now you don't have a sealed system and your closed transfer is compromised anyway.

I am playing with some alternative solutions. One I have had good luck with before is keg priming. Just do a half ass purge, fill the keg, and add some sugar. Just like bottle priming. Unlike bottle priming you can also dry hop the keg at the same time. I never had much issue with settling the yeast, pulling and dumping first 2-3 pints with this method but this year will try the clear beer draft system and see how that goes.

Second strategy I am checking out is a small metabisulfite addition at kegging time. This might be able to remove the oxygen introduced by sloppy kegging. Read about it on one of those experiments and thought I'd give it a try on current batch. Can't say for sure it helped but didn't seem to create any off flavors either and the beer is still drinking well.

Last thing that has always worked well for me is to leave keg one alone, dry hop keg 2 when I start serving keg 1, then dryhop keg 3 when I start serving keg 2. Maybe I am losing hop flavors and aromas to oxidation so just add them back.

Anyway I'd be really curious to hear from homebrewers that have done closed transfers with regular fermentors and then switched over to something like the Spike CF10. Does this make packaging day much easier? Or is it just shifting the work and aggravation around?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)