Phew, just got thru all 21 pages.  Long time lurker, first time poster.

Long time lurker, first time poster.

Regarding the 6.5 version:

Looking to ferment in corny kegs, as I have several 5 gal I just picked up for a song.

I realize this will limit my batch size to approx 4.5 gal into the fermenter/keg, which is fine as smaller batches work better for me, but I'd prefer to maximize my volume in the fermenter if possible.

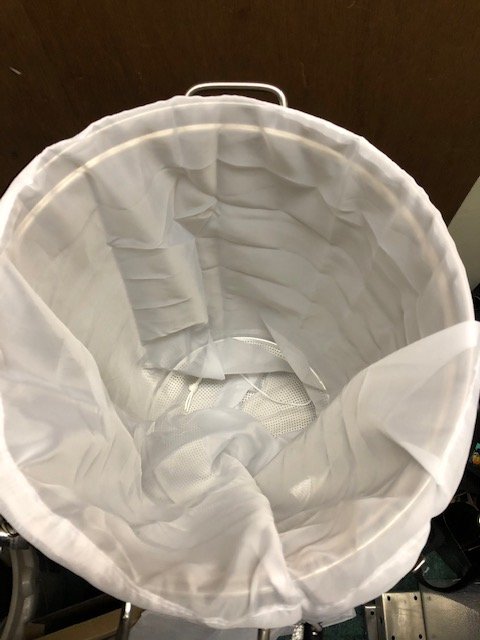

I am keeping the 10 gal round cooler mash tun + brew bag a buddy of mine used with his old propane setup for MIAB/batch sparging.

So I'm only looking at the foundry as a decent boil kettle for the majority of my batches.

Being able to use 120V or 240V with the proper outlets out of the gate is a distinct advantage compared to other similar options.

The 6.5 is recommended for 3 gal or smaller batches, but that was assuming kettle volume would be needed to account for the grain in the pipe during mashing, which I'd only use occasionally.

The 10.5 is currently a bit on the big side for the brews I'm planning, based on what I've been reading in the thread. (I like the variety with smaller batches, 5 gal of any one is tough to work thru these days).

How close would I be pushing it after accounting for hop/trub loss in the kettle (and avoiding boil overs) to get 4.5 gal of wort into the fermenter, 5.5 gallons pre-boil ish? Has anybody tried this?

Great info everyone, I've learned alot just by reading.

Cheers.

Regarding the 6.5 version:

Looking to ferment in corny kegs, as I have several 5 gal I just picked up for a song.

I realize this will limit my batch size to approx 4.5 gal into the fermenter/keg, which is fine as smaller batches work better for me, but I'd prefer to maximize my volume in the fermenter if possible.

I am keeping the 10 gal round cooler mash tun + brew bag a buddy of mine used with his old propane setup for MIAB/batch sparging.

So I'm only looking at the foundry as a decent boil kettle for the majority of my batches.

Being able to use 120V or 240V with the proper outlets out of the gate is a distinct advantage compared to other similar options.

The 6.5 is recommended for 3 gal or smaller batches, but that was assuming kettle volume would be needed to account for the grain in the pipe during mashing, which I'd only use occasionally.

The 10.5 is currently a bit on the big side for the brews I'm planning, based on what I've been reading in the thread. (I like the variety with smaller batches, 5 gal of any one is tough to work thru these days).

How close would I be pushing it after accounting for hop/trub loss in the kettle (and avoiding boil overs) to get 4.5 gal of wort into the fermenter, 5.5 gallons pre-boil ish? Has anybody tried this?

Great info everyone, I've learned alot just by reading.

Cheers.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)