Big Monk

Trappist Please! 🍷

- Joined

- Dec 24, 2015

- Messages

- 2,192

- Reaction score

- 1,151

In order to clear the air about what spreadsheets do what and how, as well as to see how they react to equivalent input data, I am going to run through 2 distinct scenarios with each program and then discuss how they estimate in their stock form, how their estimations can be brought closer to one another with slight modifications to the equations, and make recommendations based on those observations.

I will only be analyzing Grist pH, i.e. the effect the grain bill will have on pH in the absence of minerals, alkaline source water, and additional acids or bases. (I have expanded to look at some other variables as well, including mineralization, volume, and Sauermalz.) I think the places where most sheets/programs differ is in how they handle malt. The differences in how they handle minerals, alkaline source water, and additional acids or bases could be easily rectified as the fundamentals behind calculating those things is bulletproof.

The participants:

EZ Water 3.0.2

Brun Water 4.2

Mash Made Easy 5.20

Brewer's Friend Water/Recipe Calculator

ezRecipe 1.24

MpH 3.0

Brewing Engine 0.81 (Linear)

Brewing Engine 0.81 (Polynomial)

UPDATE:

I removed Kaiser Water 1.58.

Changed to Brun Water 4.2.

The inputs:

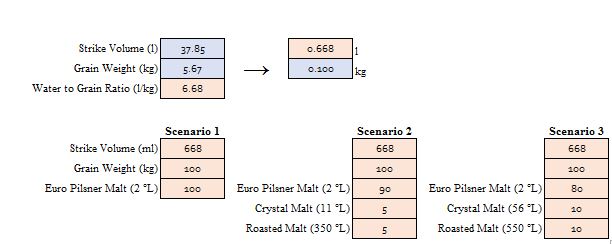

No-sparge Mash - 10 gallons/37.85 liters

Grain Amount - 12.50 pounds/5.67 kg

Grain Bill 1 - 100% Continental Pilsner Malt (2L with 5.80 DI pH)

Grain Bill 2 - 90% Continental Pilsner Malt (2L with 5.80 DI pH)

5% Light Crystal Malt (11L with 5.19 DI pH)

5% Light Roast Malt (350L with 4.69 DI pH)

Grain Bill 3 - 80% Continental Pilsner Malt (2L with 5.80 DI pH)

10% Medium Crystal Malt (56L with 4.83 DI pH)

10% Dark Roast Malt (550L with 4.48 DI pH)

Source Water - Distilled/RO with 1.58 mg/l Alkalinity as CaCO3

The Scenarios:

#1 - All 3 grain bills will be run through each calculator using equal inputs and no coding changes/external calculations. The pH estimation will be noted and put into a table.

#2 - All 3 grain bills will be run through each calculator using equal inputs but with coding changes to equalize DI pH for the grains. If this function is enabled in each spreadsheet it will be used, if not, hand calculations using the software's known equations will be conducted. The pH estimation will be noted and put into a table.

Both tables will be compared to note differences and similarities, as well as to provided a springboard for conversation.

Stay tuned...

Please hold off on posting any of your own results until I get my tables posted in this thread. We can analyze the results and troubleshoot together.

I will only be analyzing Grist pH, i.e. the effect the grain bill will have on pH in the absence of minerals, alkaline source water, and additional acids or bases. (I have expanded to look at some other variables as well, including mineralization, volume, and Sauermalz.) I think the places where most sheets/programs differ is in how they handle malt. The differences in how they handle minerals, alkaline source water, and additional acids or bases could be easily rectified as the fundamentals behind calculating those things is bulletproof.

The participants:

EZ Water 3.0.2

Brun Water 4.2

Mash Made Easy 5.20

Brewer's Friend Water/Recipe Calculator

ezRecipe 1.24

MpH 3.0

Brewing Engine 0.81 (Linear)

Brewing Engine 0.81 (Polynomial)

UPDATE:

I removed Kaiser Water 1.58.

Changed to Brun Water 4.2.

The inputs:

No-sparge Mash - 10 gallons/37.85 liters

Grain Amount - 12.50 pounds/5.67 kg

Grain Bill 1 - 100% Continental Pilsner Malt (2L with 5.80 DI pH)

Grain Bill 2 - 90% Continental Pilsner Malt (2L with 5.80 DI pH)

5% Light Crystal Malt (11L with 5.19 DI pH)

5% Light Roast Malt (350L with 4.69 DI pH)

Grain Bill 3 - 80% Continental Pilsner Malt (2L with 5.80 DI pH)

10% Medium Crystal Malt (56L with 4.83 DI pH)

10% Dark Roast Malt (550L with 4.48 DI pH)

Source Water - Distilled/RO with 1.58 mg/l Alkalinity as CaCO3

The Scenarios:

#1 - All 3 grain bills will be run through each calculator using equal inputs and no coding changes/external calculations. The pH estimation will be noted and put into a table.

#2 - All 3 grain bills will be run through each calculator using equal inputs but with coding changes to equalize DI pH for the grains. If this function is enabled in each spreadsheet it will be used, if not, hand calculations using the software's known equations will be conducted. The pH estimation will be noted and put into a table.

Both tables will be compared to note differences and similarities, as well as to provided a springboard for conversation.

Stay tuned...

Please hold off on posting any of your own results until I get my tables posted in this thread. We can analyze the results and troubleshoot together.

Last edited: