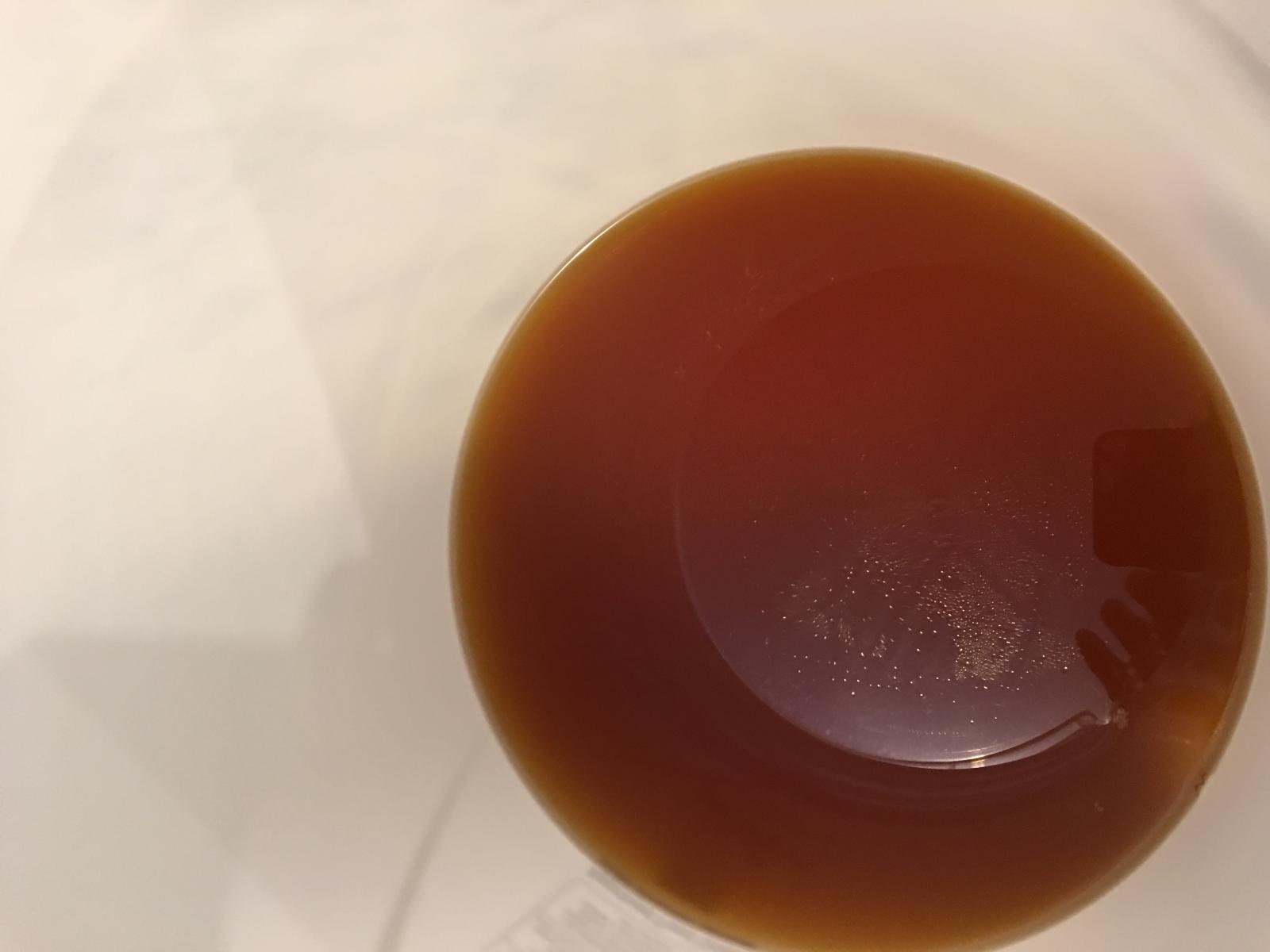

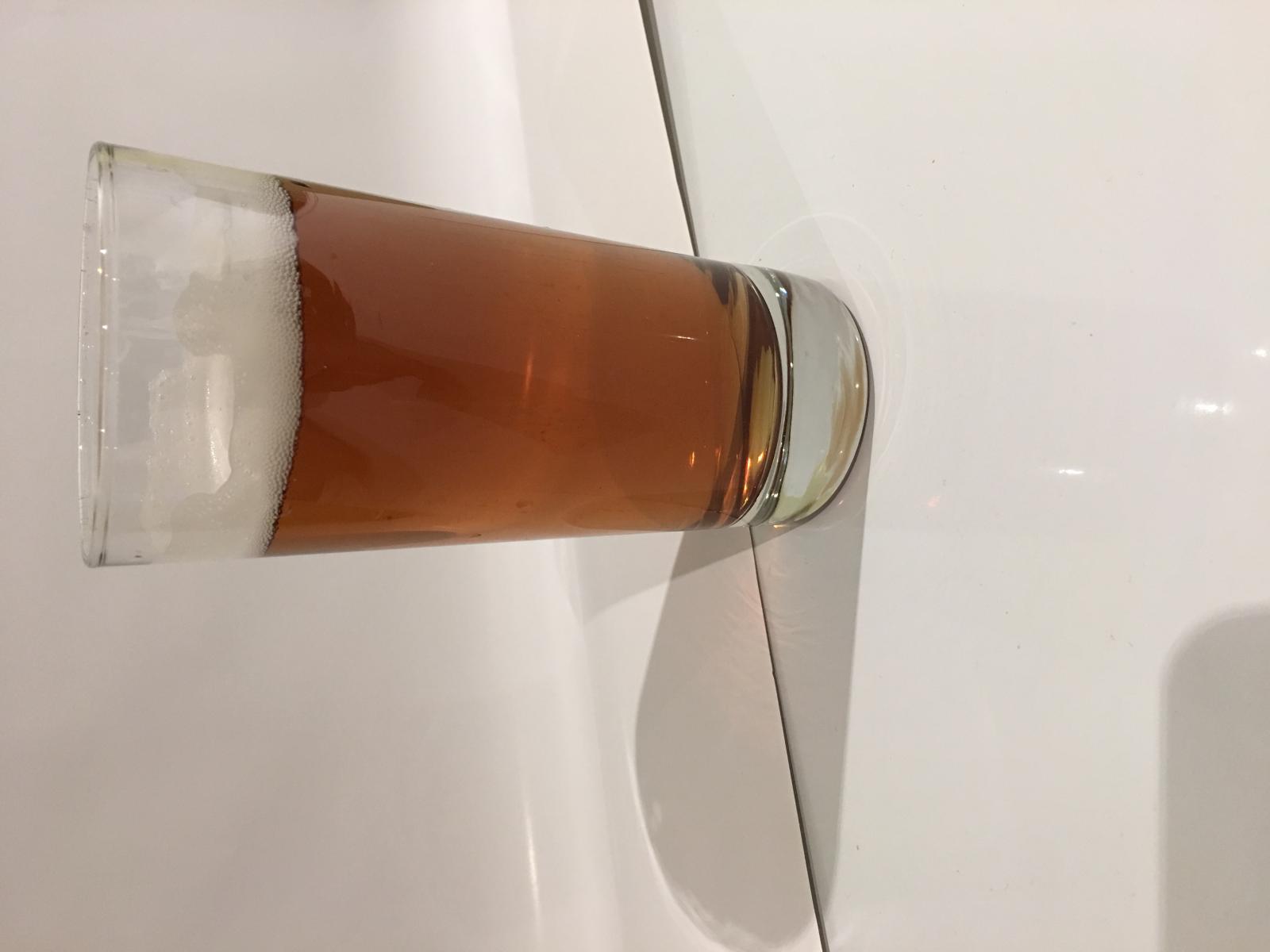

Hey everyone. I'm still pretty new to homebrewing with 10 batches under my belt (last 6 have been all-grain). Up until my last batch everything has been going pretty smoothly and I have been consistent with my process. I'm very thorough with sanitation and my beers have been coming out really good. There seems to be something wrong with my last batch, an American Wheat (recipe below). The color is off (almost a copper color as you can see from the second attachment). At bottling time, the color looked as it should (first attachment). It still smells good, although the weird color may be playing tricks with my mind as the beer (at least to me) starts tasting flat towards the end of the beer (it is carbonated just fine). I can't put my finger on it but something tastes just a bit off.

This beer spent 3 weeks fermenting reaching a FG of 1.008. My efficiency was bad on this batch likely due to a bad crush. I dry-hopped for 7 days, cold crashed for 3 days, then bottled. Bottling day was on Sept. 16, 2016. I let it bottle condition for 4 weeks then cracked a few open only to find the color way off. I opened another 2 bottles last night. One was the same off color, and the other had incidentally not been capped properly. The interesting thing about the badly capped bottle is that the color of the beer was exactly as it should have been. The taste was good too, except that it was extremely under-carbonated (obviously).

Not sure if oxidation took place or if the batch is infected. As for oxidation, there was definitely no splashing - my process was identical to every other batch I have done. The one difference in this batch was that I cold crashed. In my 8 Gallon batch there were 5oz of dry hops (pellets).

Hoping someone can help me figure out what's going on with this batch.

Thanks!

12.6 oz Rice Hulls

10 lbs (2 Row)

8 lbs White Wheat Malt

1 lbs 14.2 oz Oats, Flaked

1.67 oz Magnum [12.40 %]

1.73 oz Amarillo [7.70 %]

2.00 oz Centennial [7.60 %]

4.50 tsp Coriander Seed (Boil 10.0 mins)

1.50 tsp Orange Peel, Sweet (Boil 5.0 mins)

4.00 oz Amarillo [7.70 %] - Boil 0.0 min

2 pkg Safale American (DCL/Fermentis #US-05)

5.00 oz Amarillo [7.70 %] - Dry Hop 7.0

Chris

This beer spent 3 weeks fermenting reaching a FG of 1.008. My efficiency was bad on this batch likely due to a bad crush. I dry-hopped for 7 days, cold crashed for 3 days, then bottled. Bottling day was on Sept. 16, 2016. I let it bottle condition for 4 weeks then cracked a few open only to find the color way off. I opened another 2 bottles last night. One was the same off color, and the other had incidentally not been capped properly. The interesting thing about the badly capped bottle is that the color of the beer was exactly as it should have been. The taste was good too, except that it was extremely under-carbonated (obviously).

Not sure if oxidation took place or if the batch is infected. As for oxidation, there was definitely no splashing - my process was identical to every other batch I have done. The one difference in this batch was that I cold crashed. In my 8 Gallon batch there were 5oz of dry hops (pellets).

Hoping someone can help me figure out what's going on with this batch.

Thanks!

12.6 oz Rice Hulls

10 lbs (2 Row)

8 lbs White Wheat Malt

1 lbs 14.2 oz Oats, Flaked

1.67 oz Magnum [12.40 %]

1.73 oz Amarillo [7.70 %]

2.00 oz Centennial [7.60 %]

4.50 tsp Coriander Seed (Boil 10.0 mins)

1.50 tsp Orange Peel, Sweet (Boil 5.0 mins)

4.00 oz Amarillo [7.70 %] - Boil 0.0 min

2 pkg Safale American (DCL/Fermentis #US-05)

5.00 oz Amarillo [7.70 %] - Dry Hop 7.0

Chris

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)