An Ankoù

Well-Known Member

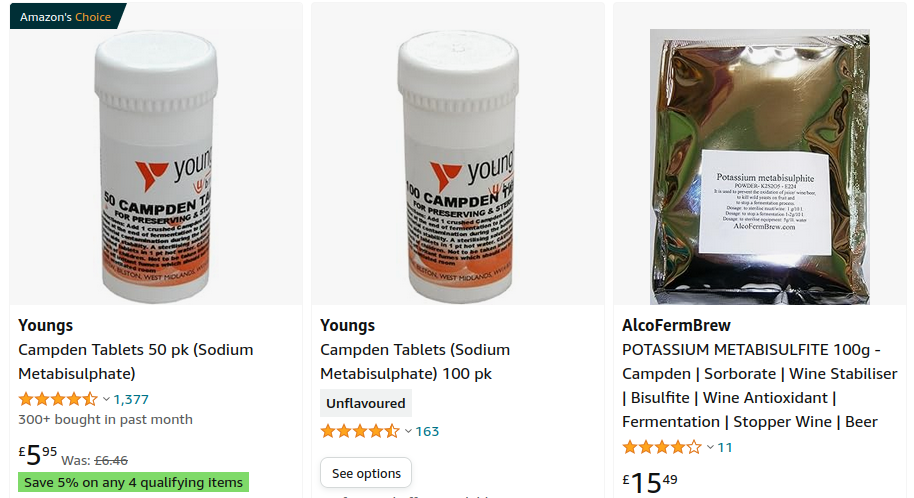

That's almost certainly chlorine or chloramine in the water supply. It can easily be corrected with half a Campden tablet or a pinch of sodium (or potassium) metabisulphite in the mash and in the sparge liquor. The chlorine compounds react with the polyphenols in the hops during the boil to give an "antiseptic" flavour which has a very low taste threshhold and it won't improve with time.My previous brew has been in the bottle for 3 months and it is still undrinkable. I gotta say that off flavor existed even before bottling, but now it's overpowering all the other flavors, so here's what I'm gonna do next time, I will use bottled water, up the og, ferment cooler, more time in the carboy, then gelatin +cold crashing, more time in the bottle. I'll see if that changes anything, but given the problem exists in all my homebrews despite the fact that I used different yeast strains, different recipes, the problem might be my water. That's what all my batches have in common

In short, the beer;s ruined. Chuck it and start again, but don't let any untreated water get into the brew before bottling.

I was taken by surprise when I moved to France. Previously I had been using water from the hot-water header tank of my old house and here I started using water directly from the mains. My beer was sometimes ok and sometimes undrinkable. I discovered that instead of simply chlorinating the supply, they "flushed" the system with chlorine from time to time to keep the pipes clean.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)