mr_lahey

I am the liquor

- Joined

- Apr 1, 2020

- Messages

- 40

- Reaction score

- 30

Brewed my first all-grain batch on the weekend. Here is how it went down. (Recipe at bottom)

Recipe:

SNPA Clone

Batch Volume: 5.5 gal

Boil Time: 60 min

Mash Water: 4.04 gal

Sparge Water: 4.67 gal

Total Water: 8.71 gal

Boil Volume: 7.4 gal

Target Gravs

Pre-Boil Gravity: 1.044

Original Gravity: 1.054

Mash

Strike Temp — 164.3 °F

Temperature — 153 °F — 60 min

Malts (11 lb 3.9 oz)

10 lb 6.8 oz (92.8%) — Briess Brewers Malt 2-Row — Grain — 1.8 SRM

13.1 oz (7.3%) — Great Western Crystal 2-Row — Grain — 60 SRM

Hops (5.75 oz)

0.55 oz (22 IBU) — Magnum 11.5% — Boil — 60 min

0.68 oz (9 IBU) — Perle 5.2% — Boil — 30 min

1.17 oz (8 IBU) — Cascade 5.3% — Boil — 10 min

1.81 oz — Cascade 5.3% — Boil — 0 min

1.54 oz — Cascade 5.3% — Dry Hop — day 4

Yeast

1 pkg — Fermentis US-05 Safale American

Equipment:

Very basic, no pumps.

10 gallon orange cooler mashtun with false bottom

5 gallon orange cooler HLT

10 gal SS kettle with bazooka tube filter

- For software I used Brewfather for recipe and tracking, and Bru’n water for additions and acid. Estimated mash pH 5.39. I let Brewfather do a lot of the calculations for water amounts and scaled the recipe for the batch size.

- Target mash temp: 153f, Actual mash temp 154f. After 60 minutes temperature dropped to 151f. I think this is alright.

- Vorlauf with pyrex cup for 30 minutes, still some debris in the runnings, but much clearer in general. Drain to kettle before starting batch sparge.

- Oops – bad Sparge temp. After pouring sparge water in and stirring, temperature is at 160. Inexperienced me says “oops, oh well” instead of trying to fix it.

- Vorlauf for 30 minutes and then start draining to the kettle. Its running very slow. Let it drain into kettle at a trickle for about an hour until it stops completely. Still a gallon short of pre-boil target volume, gravity reading at 1.055, pre-boil target is 1.044

- Added more water, no effect. Stirred, no effect. Blow-back method, no effect.

- Started scooping water out with pyrex cup and pouring into kettle through a steel mesh kitchen strainer. Do this for a bit until I start compressing the grain too much to scoop out any more. Still about 0.4 gal short of pre-boil vol. Top up the rest with pre-boiled water into the kettle. What am I even doing at this point.

- pre-boil gravity 1.051

- Start boil and schedule - This all went smoothly. Meanwhile, Sat down, had a beer, and contemplated the chaos that just happened between sparge and now. Aprox 3.5 hours have passed since I mixed in the Sparge water. It is like my brain turned off when the sparge got stuck. Feeling like I screwed up this batch.

- Boil done. First time using home made immersion chiller. Worked pretty good. 20 minutes from boil to 68f.

- post-boil gravity 1.054

- Lots of hops in this one (pellets). Debris clogging up the bazooka filter. Had to stand over the kettle and continually scrape the filter with my brew spoon for almost the whole drain into the fermenter. Took about 45 minutes. Wort temp heated back up a bit during this, since the garage was so warm.

- Put fermenter in fermentation chamber to cool back down before pitching yeast. Eventually pitched at 70f.

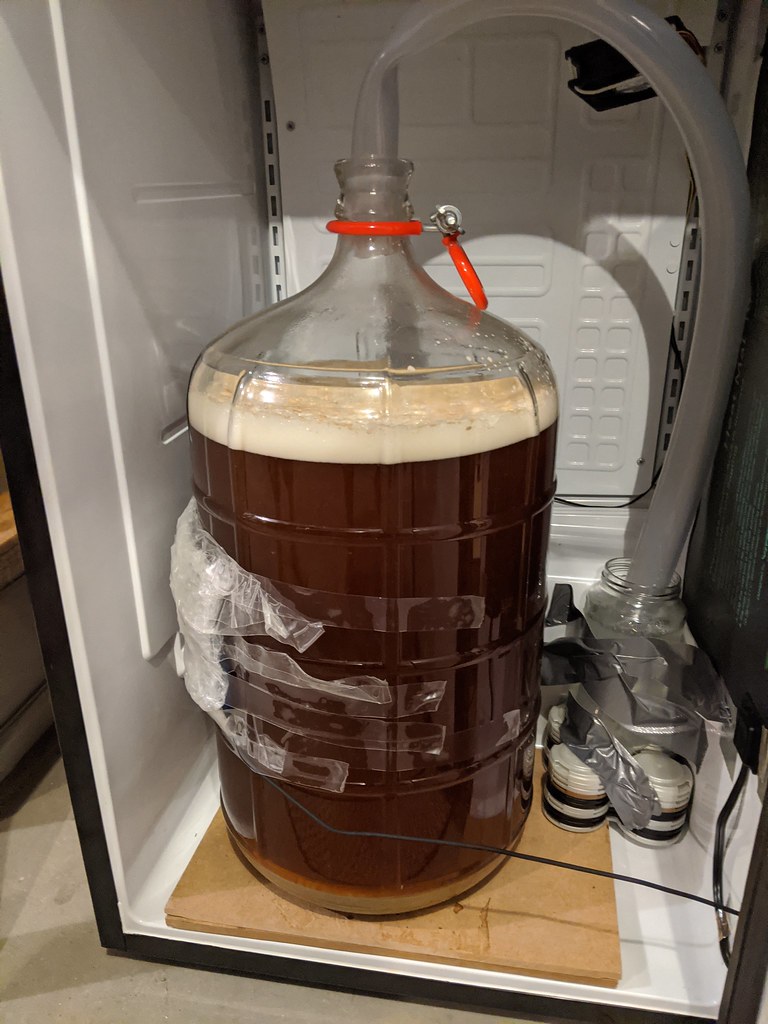

- After 24 hours: bubbling away. Krausen starting to rise. Smells decent. Lots of debris settled down to bottom. Starting to feel a bit better about it now.... Maybe it will be drinkable.

Recipe:

SNPA Clone

Batch Volume: 5.5 gal

Boil Time: 60 min

Mash Water: 4.04 gal

Sparge Water: 4.67 gal

Total Water: 8.71 gal

Boil Volume: 7.4 gal

Target Gravs

Pre-Boil Gravity: 1.044

Original Gravity: 1.054

Mash

Strike Temp — 164.3 °F

Temperature — 153 °F — 60 min

Malts (11 lb 3.9 oz)

10 lb 6.8 oz (92.8%) — Briess Brewers Malt 2-Row — Grain — 1.8 SRM

13.1 oz (7.3%) — Great Western Crystal 2-Row — Grain — 60 SRM

Hops (5.75 oz)

0.55 oz (22 IBU) — Magnum 11.5% — Boil — 60 min

0.68 oz (9 IBU) — Perle 5.2% — Boil — 30 min

1.17 oz (8 IBU) — Cascade 5.3% — Boil — 10 min

1.81 oz — Cascade 5.3% — Boil — 0 min

1.54 oz — Cascade 5.3% — Dry Hop — day 4

Yeast

1 pkg — Fermentis US-05 Safale American

Equipment:

Very basic, no pumps.

10 gallon orange cooler mashtun with false bottom

5 gallon orange cooler HLT

10 gal SS kettle with bazooka tube filter

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)