Hi there, I use a self build PID system to control a 25L electric kettle. It has been a long time since I use it and I think it is realible but there is a thing that is now missing and gets my nut off. I use a Sestos d1s-vr-220 PID and I want to set an alarm so that it can inform me when a fixed temperature is reached in the kettle. I wired the PID with a 220V buzzer like this:

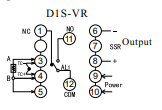

Line (brown) and neutral (blue) are both controlled by an ON-OFF bipolar switch, neutral is then wired directly to the alarm whereas line is wired to 12 PID pin, as follow:

11 PID pin is then wired to the alarm. Is this system correctly wired?

Then, I need to set the PID alarm up but I don't understand how to do, accordingly to the following manual user: http://www.sestos-hk.com/english/download/d1s-en.pdf.

Is there someone so kind to explain me how to do in order to set the alarm up and be informed by the system when a certain temperature is reached in the kettle during the mash?

I thank you and look forward to hearing from you.

See you soon and have a great homebrewing time

Tyr

Line (brown) and neutral (blue) are both controlled by an ON-OFF bipolar switch, neutral is then wired directly to the alarm whereas line is wired to 12 PID pin, as follow:

11 PID pin is then wired to the alarm. Is this system correctly wired?

Then, I need to set the PID alarm up but I don't understand how to do, accordingly to the following manual user: http://www.sestos-hk.com/english/download/d1s-en.pdf.

Is there someone so kind to explain me how to do in order to set the alarm up and be informed by the system when a certain temperature is reached in the kettle during the mash?

I thank you and look forward to hearing from you.

See you soon and have a great homebrewing time

Tyr

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)