Can anyone offer advice on how to calculate the amount of sugar (corn/dextrose, in my case) I'd need to add to each bottle when bottling partially-carbonated beer?

For example, with 6 gallons of ale sitting in a FermZilla, 15 PSI at 70F degrees at the end of fermentation. I can easily bottle with a counter pressure bottle filler, but I know that the beer currently has insufficient carbonation so that if I were to bottle it as-is, when a refrigerated bottle gets opened, it would be under-carbonated. I'm sure that if I could calculate the needed amount of sugar, I could ensure that each bottle would increase carbonation to the proper levels.

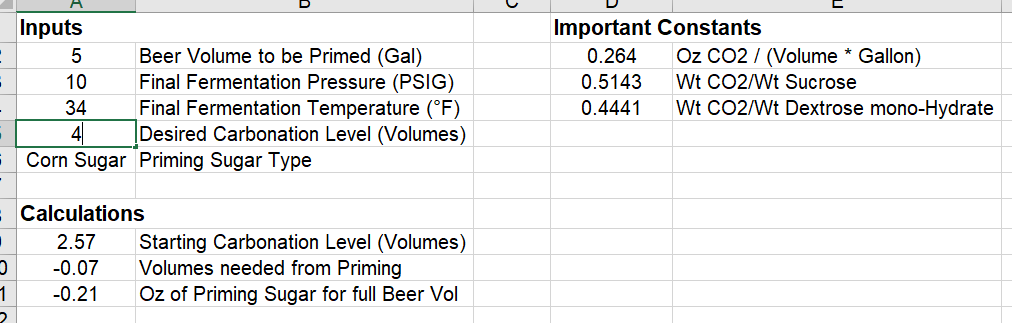

One thought I had was using the following steps, but maybe I'm over-thinking it or maybe I'm missing something?

1. Determine the CO2 volume in the FermZilla.

2. Determine the desired CO2 volume if it were fully-carbonated.

3. Subtract 1 from 2, giving the CO2 volume delta I'd need to attain with sugar.

4. Use a carbonation calculator to determine the amount of sugar needed to get that delta.

Also:

I'm using only bottles because I can't use a keezer/kegerator at this time.

I know I can increase PSI in the fermenter, and I may choose to do this later, though that gets uncomfortably close to the limit of a FermZilla's pressure rating.

I could also xfer the beer to a keg, force-carbonate it further, and then bottle it.

Yes, I know I could easily carbonate into corny kegs, and I might try this later, too, just for simplicity's sake.

My bottling technique pre-FermZilla was adding 5.8 - 6oz of dextrose into a bottling bucket, then bottling.

For example, with 6 gallons of ale sitting in a FermZilla, 15 PSI at 70F degrees at the end of fermentation. I can easily bottle with a counter pressure bottle filler, but I know that the beer currently has insufficient carbonation so that if I were to bottle it as-is, when a refrigerated bottle gets opened, it would be under-carbonated. I'm sure that if I could calculate the needed amount of sugar, I could ensure that each bottle would increase carbonation to the proper levels.

One thought I had was using the following steps, but maybe I'm over-thinking it or maybe I'm missing something?

1. Determine the CO2 volume in the FermZilla.

2. Determine the desired CO2 volume if it were fully-carbonated.

3. Subtract 1 from 2, giving the CO2 volume delta I'd need to attain with sugar.

4. Use a carbonation calculator to determine the amount of sugar needed to get that delta.

Also:

I'm using only bottles because I can't use a keezer/kegerator at this time.

I know I can increase PSI in the fermenter, and I may choose to do this later, though that gets uncomfortably close to the limit of a FermZilla's pressure rating.

I could also xfer the beer to a keg, force-carbonate it further, and then bottle it.

Yes, I know I could easily carbonate into corny kegs, and I might try this later, too, just for simplicity's sake.

My bottling technique pre-FermZilla was adding 5.8 - 6oz of dextrose into a bottling bucket, then bottling.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)