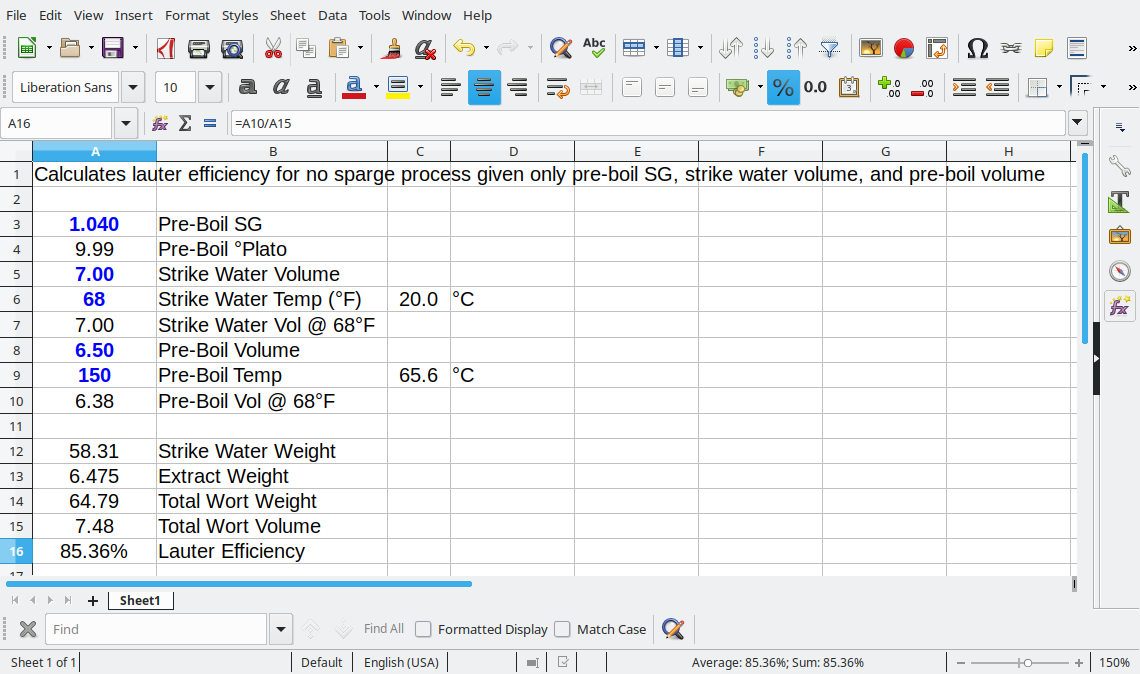

Just did a Kolsch this weekend. I used a couple online calculators and both gave me 94% mash efficiency. I thought 80% was about the best that can be normally be done.

BIAB. 7 gallons total mash water and 6.5 gallons left after pulling the bag and a few good squeezes. Total mash time was about 3 hours with constant recirc sine I have a large dead space below the basket holding my bag. Mash temp was 148-150' with a digital controller maintaining constant temps during the recirc and then stepped up to 170 for mash out.

grain bill: 7.5# total

6# German Kolsch malt

1# American pilsner malt

0.5# American Vienna malt

SG 1.040

OG 1.044

BIAB. 7 gallons total mash water and 6.5 gallons left after pulling the bag and a few good squeezes. Total mash time was about 3 hours with constant recirc sine I have a large dead space below the basket holding my bag. Mash temp was 148-150' with a digital controller maintaining constant temps during the recirc and then stepped up to 170 for mash out.

grain bill: 7.5# total

6# German Kolsch malt

1# American pilsner malt

0.5# American Vienna malt

SG 1.040

OG 1.044

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)