sleizure

Active Member

Alot of time has passed since I've been able to give an update. I was down for the count for most of September as I put an axe through my foot (!) and was waiting for parts to arrive. I also dunked my phone in the River and lost a few photos, but this one has the goods.

I received 8 new 4 inch casters in the mail that work much better than the 2 inch ones. The downside to this is I had to take apart the entire unit as it was far too big and heavy to flip on its side put together. I had built these braces on the back due to the freezer moving about (looking back I should have made the frame flat on the bottom) so getting those off and back on later on perfectly was fun.

Lifting off the serving part of the coffin blew my back out, so this sat on the floor for 2 weeks:

The new casters are spaced evenly know, where as before they were in just any old place I decided to put them. I used big thick lag bolts to get them into the wood as the screws I used last time snapped easily. All the casters are all 360 degree rotational and are very smooth. Well, not so smooth fully loaded with 6 kegs but, better than before.

Next I had to figure out why the Keezer was lifting when I lifted the lid. I actually damaged the freezer pretty hard with lifting it up and I'm surprised I was still able to use it afterwords. Rookie mistake - since the freezer is inside the coffin and the lid and frame is longer than the freezer, and the hinges are on the freezer it made a tonne of sense that I was jamming up wood on wood causing it to lift. All the nice work and care I did with wood went out the window and I started hacking away as nice as one could with a sawzall at the frame and even some of the finished wood (!) Nobody is going to notice it, and I will hang a piece of dark brown leather if someone does notice the gaps. I felt pretty sheepish that I missed this important spot, and kicking myself as I think the whole unit is a couple inches too deep - well, here's how I could have avoided it by placing the freezer as close as possible to the back.

Here you can clearly see where the frame was catching the lid:

After I had smooth lifting with no lifting of the freezer I went and got fresh bolts for the hinges, and got to work at unpacking this linear actuator I picked up on ebay.

It's a 30 inch model apparently good for 750nm of force, which I figured oughtta lift the lid.

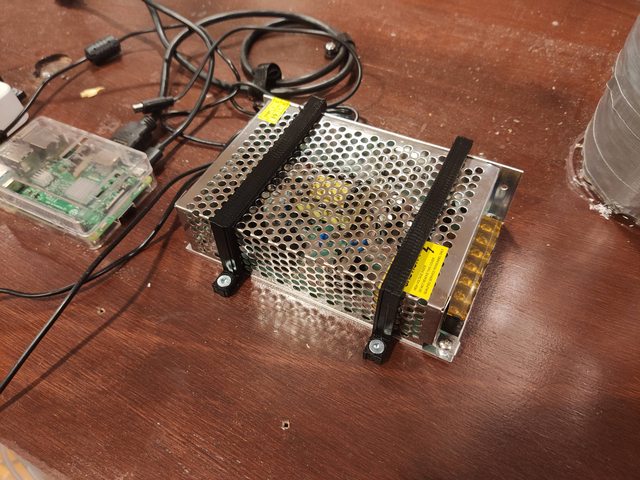

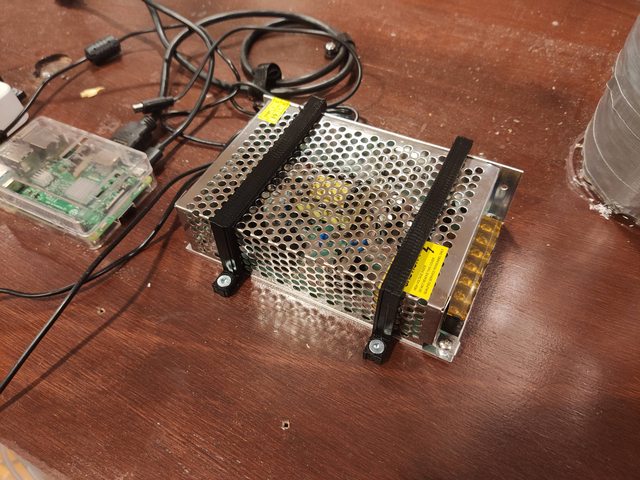

It operates at 12 volts, so I ordered a power supply from ebay, printed up some mounts on the 3d printer and got to work at putting the brackets first on the inside top of the lid, then the bottom. I had no help so most of the day was spent fiddling around trying to lift things and keep them propped up with 2x4s

I somehow lost my DPDT switch to use so i ended up wiring the thing together and twisting wires together to see if my calculations were correct on the mount placement. Seemed ok! Eventually a couple of days later I found the switch, only to find out I ordered a non momentary one, so had to order a new one. I have a fixed switch in place now, which actually works out pretty well. When the other arrives I'll make my mind up on which one I want.

I put 6 kegs of beer in it closed it down and have been drinking out of it for the past week and now prepping for the next stage, to build a motion detector to automatically turn on the screen when someone is in the room, and I still need to source out some hardwood flooring for the surface of the lid, finding unfinished flooring is harder than I originally anticipated, but I have patience on that part.

I am half an inch short of being able to put a 15lb Co2 Canister inside, too bad, I'm using a 5 right now but intend on upgrading to a 10 shortly.

More to post when I get somewhere with the surface, in the meantime, I present to you... KEEZER VIAGRA!

I received 8 new 4 inch casters in the mail that work much better than the 2 inch ones. The downside to this is I had to take apart the entire unit as it was far too big and heavy to flip on its side put together. I had built these braces on the back due to the freezer moving about (looking back I should have made the frame flat on the bottom) so getting those off and back on later on perfectly was fun.

Lifting off the serving part of the coffin blew my back out, so this sat on the floor for 2 weeks:

The new casters are spaced evenly know, where as before they were in just any old place I decided to put them. I used big thick lag bolts to get them into the wood as the screws I used last time snapped easily. All the casters are all 360 degree rotational and are very smooth. Well, not so smooth fully loaded with 6 kegs but, better than before.

Next I had to figure out why the Keezer was lifting when I lifted the lid. I actually damaged the freezer pretty hard with lifting it up and I'm surprised I was still able to use it afterwords. Rookie mistake - since the freezer is inside the coffin and the lid and frame is longer than the freezer, and the hinges are on the freezer it made a tonne of sense that I was jamming up wood on wood causing it to lift. All the nice work and care I did with wood went out the window and I started hacking away as nice as one could with a sawzall at the frame and even some of the finished wood (!) Nobody is going to notice it, and I will hang a piece of dark brown leather if someone does notice the gaps. I felt pretty sheepish that I missed this important spot, and kicking myself as I think the whole unit is a couple inches too deep - well, here's how I could have avoided it by placing the freezer as close as possible to the back.

Here you can clearly see where the frame was catching the lid:

After I had smooth lifting with no lifting of the freezer I went and got fresh bolts for the hinges, and got to work at unpacking this linear actuator I picked up on ebay.

It's a 30 inch model apparently good for 750nm of force, which I figured oughtta lift the lid.

It operates at 12 volts, so I ordered a power supply from ebay, printed up some mounts on the 3d printer and got to work at putting the brackets first on the inside top of the lid, then the bottom. I had no help so most of the day was spent fiddling around trying to lift things and keep them propped up with 2x4s

I somehow lost my DPDT switch to use so i ended up wiring the thing together and twisting wires together to see if my calculations were correct on the mount placement. Seemed ok! Eventually a couple of days later I found the switch, only to find out I ordered a non momentary one, so had to order a new one. I have a fixed switch in place now, which actually works out pretty well. When the other arrives I'll make my mind up on which one I want.

I put 6 kegs of beer in it closed it down and have been drinking out of it for the past week and now prepping for the next stage, to build a motion detector to automatically turn on the screen when someone is in the room, and I still need to source out some hardwood flooring for the surface of the lid, finding unfinished flooring is harder than I originally anticipated, but I have patience on that part.

I am half an inch short of being able to put a 15lb Co2 Canister inside, too bad, I'm using a 5 right now but intend on upgrading to a 10 shortly.

More to post when I get somewhere with the surface, in the meantime, I present to you... KEEZER VIAGRA!