You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printed Tap Handles

- Thread starter hausofstrauss

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

watermelon83

Well-Known Member

- Joined

- Sep 22, 2014

- Messages

- 743

- Reaction score

- 197

Looks like your top layer infill needs tweaking and you have a bit of slop in one of your horizontals.... lol sorry couldn't resist being a printer geek. Dis you print the hop with support or is it flat on the back? Looks great!!

CAD renderings have gone out for approval to those that made it in for the first round of prototypes.

I hope to have more slots open later this week and have STL files posted on Thingiverse.

I hope to have more slots open later this week and have STL files posted on Thingiverse.

I've got the files up on Thingiverse for anyone to download.

http://www.thingiverse.com/thing:542537

And I'm also about done with the first round of handles that people ordered, so I can make more for those that are interested.

http://www.thingiverse.com/thing:542537

And I'm also about done with the first round of handles that people ordered, so I can make more for those that are interested.

Printing the tap handles took longer than anticipated, but the results have turned out great. Along the way, I improved the geometry of the hop to reduce the voids in the print and I also experimented with clear filament and was able to modify the flask to really look like a flask with a starter in it.

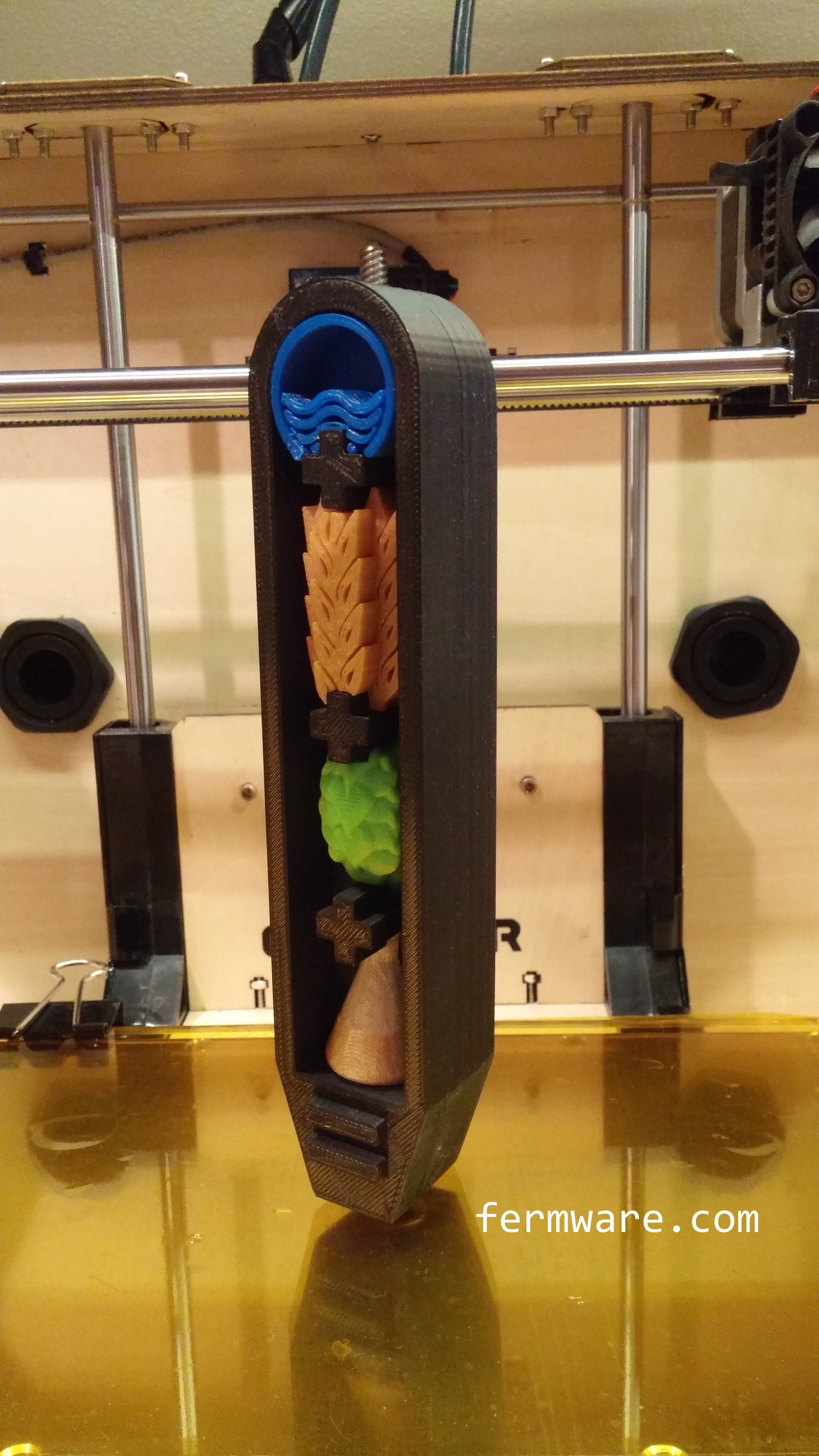

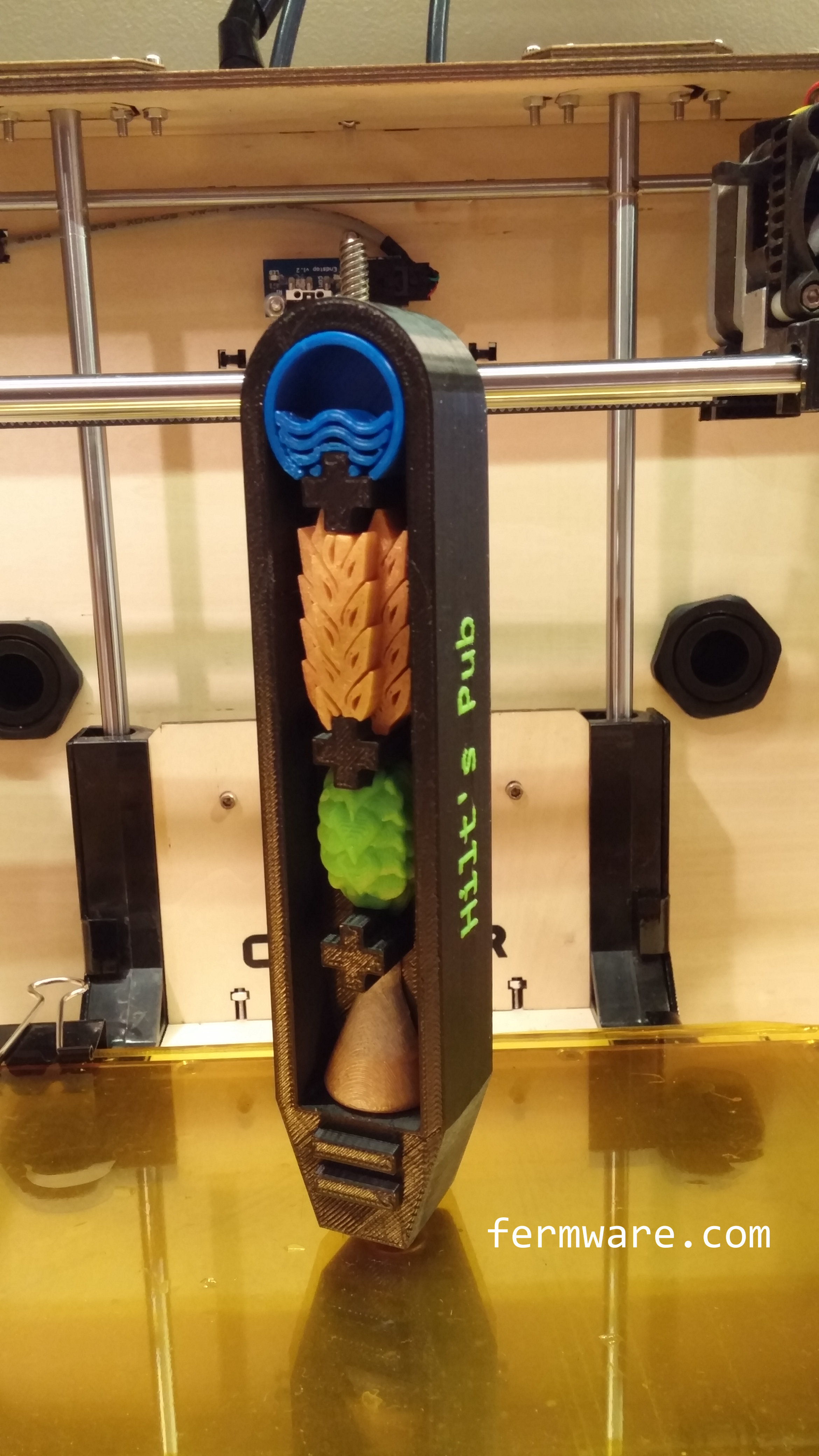

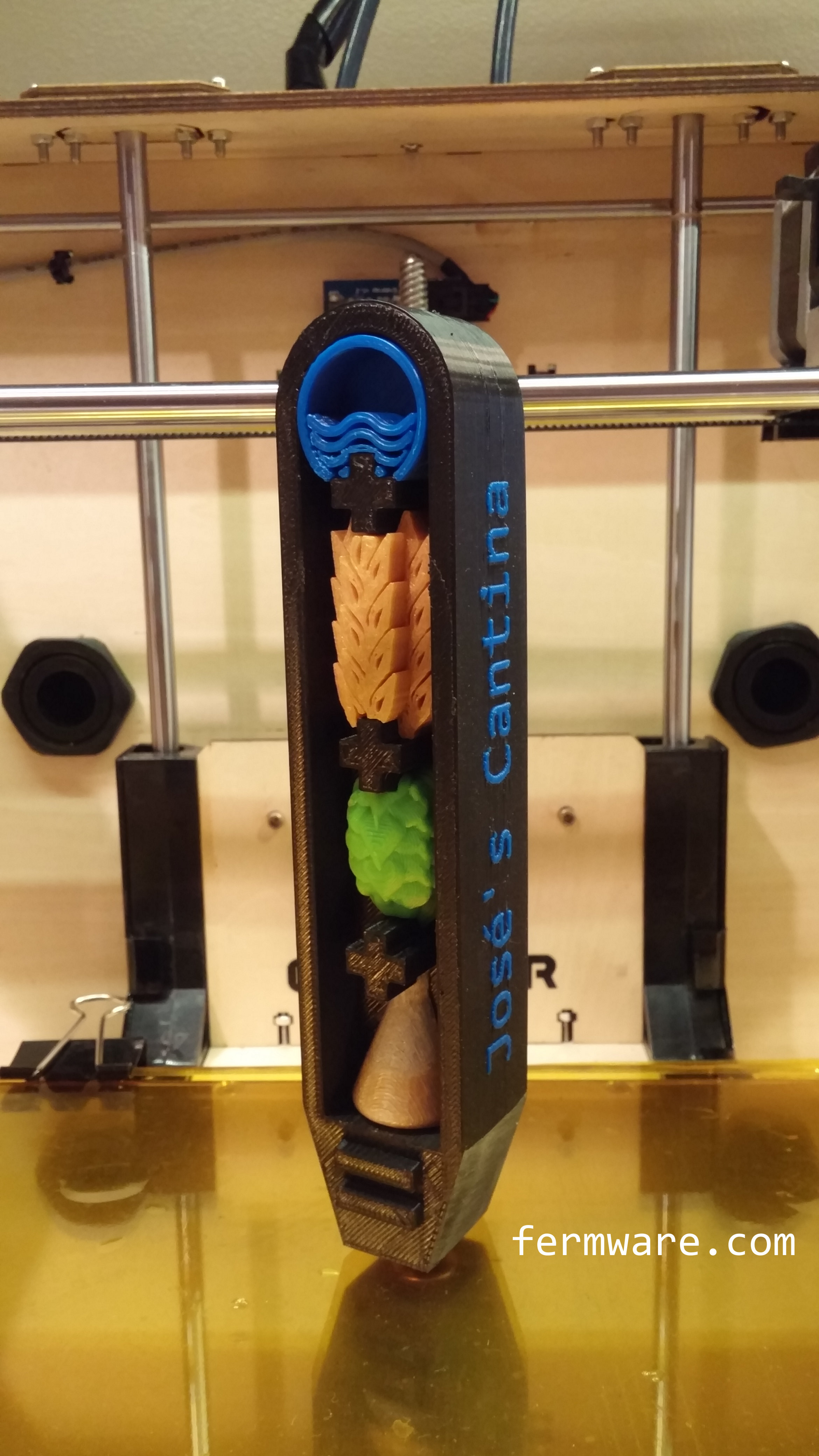

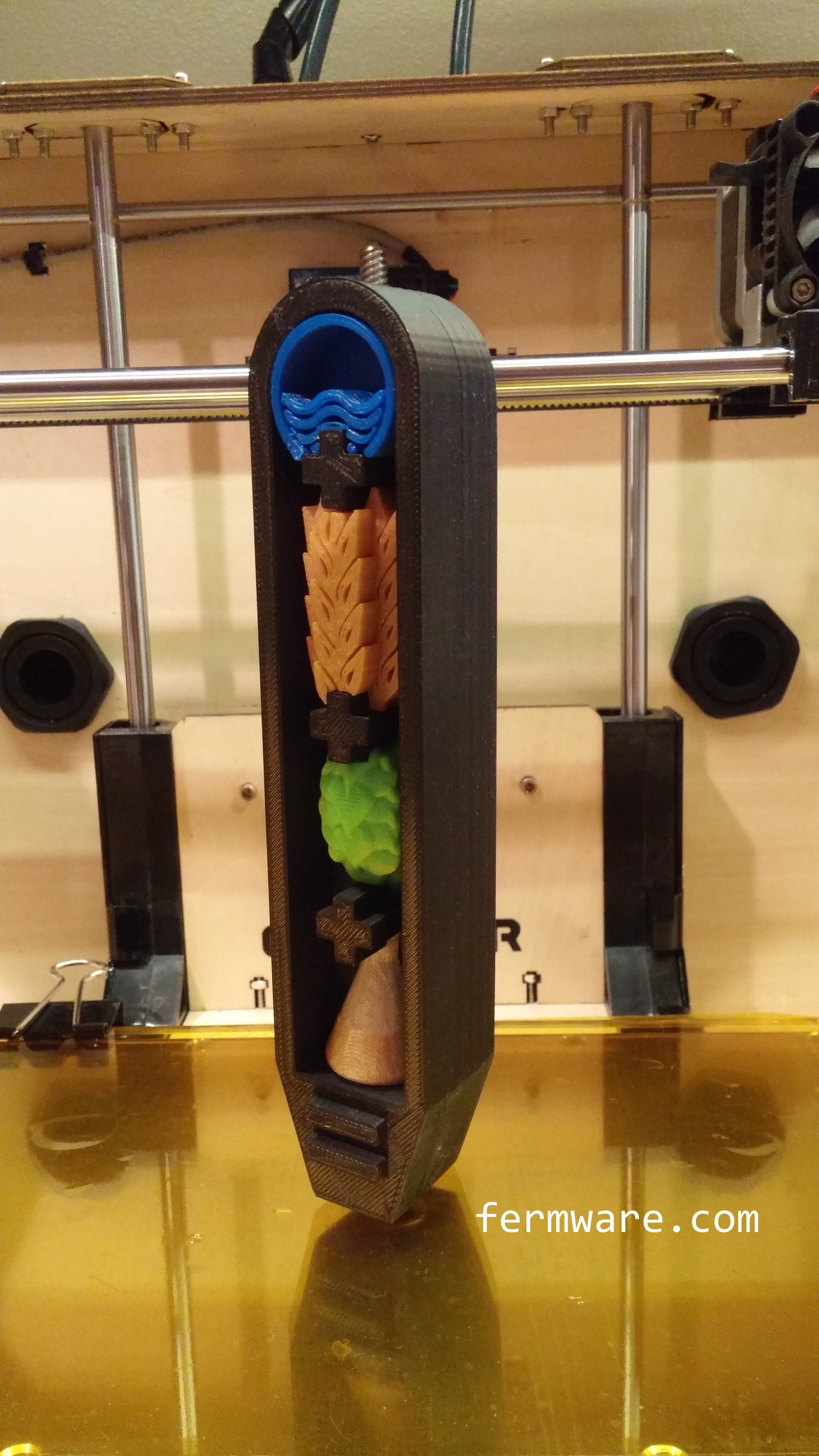

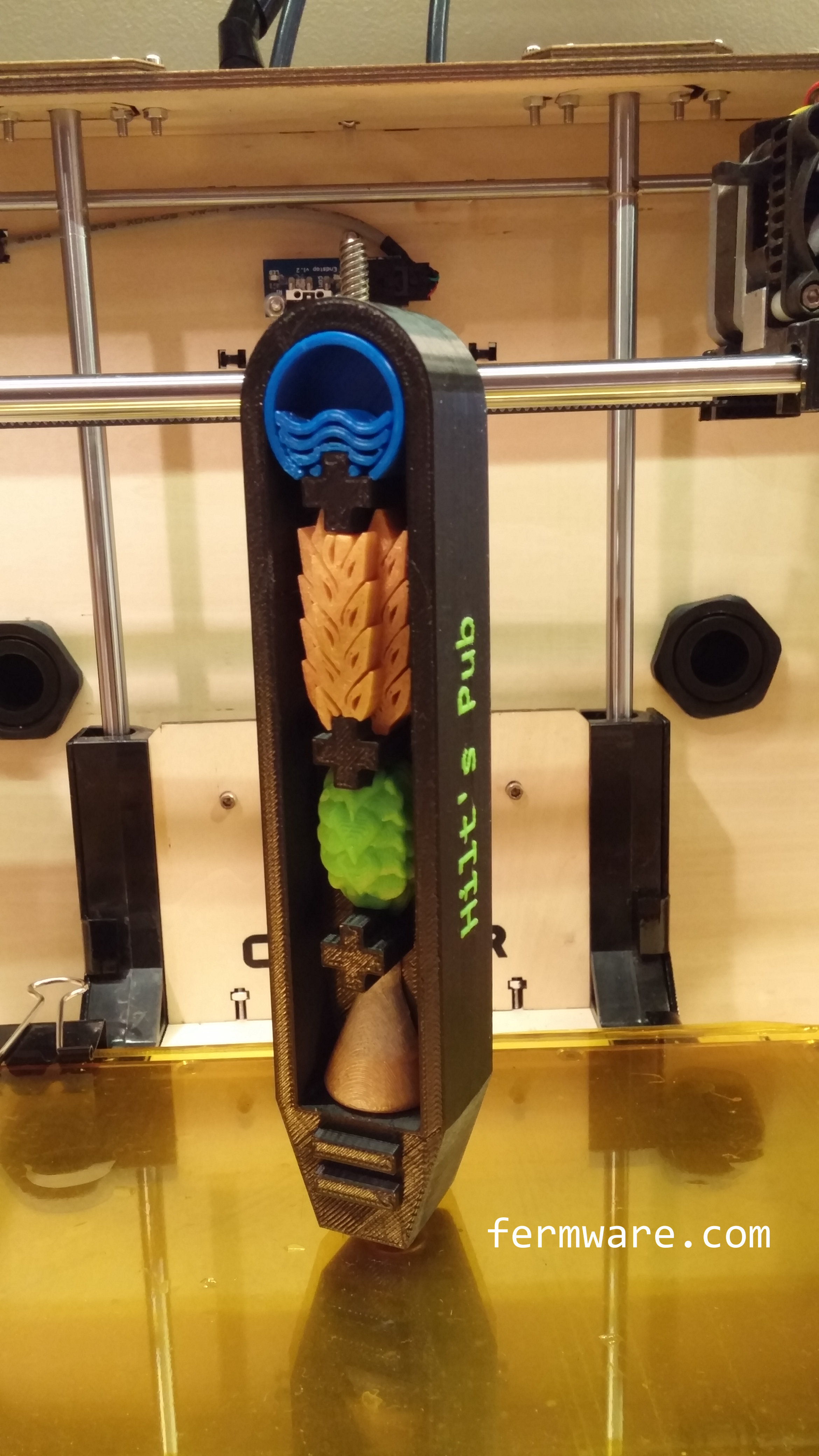

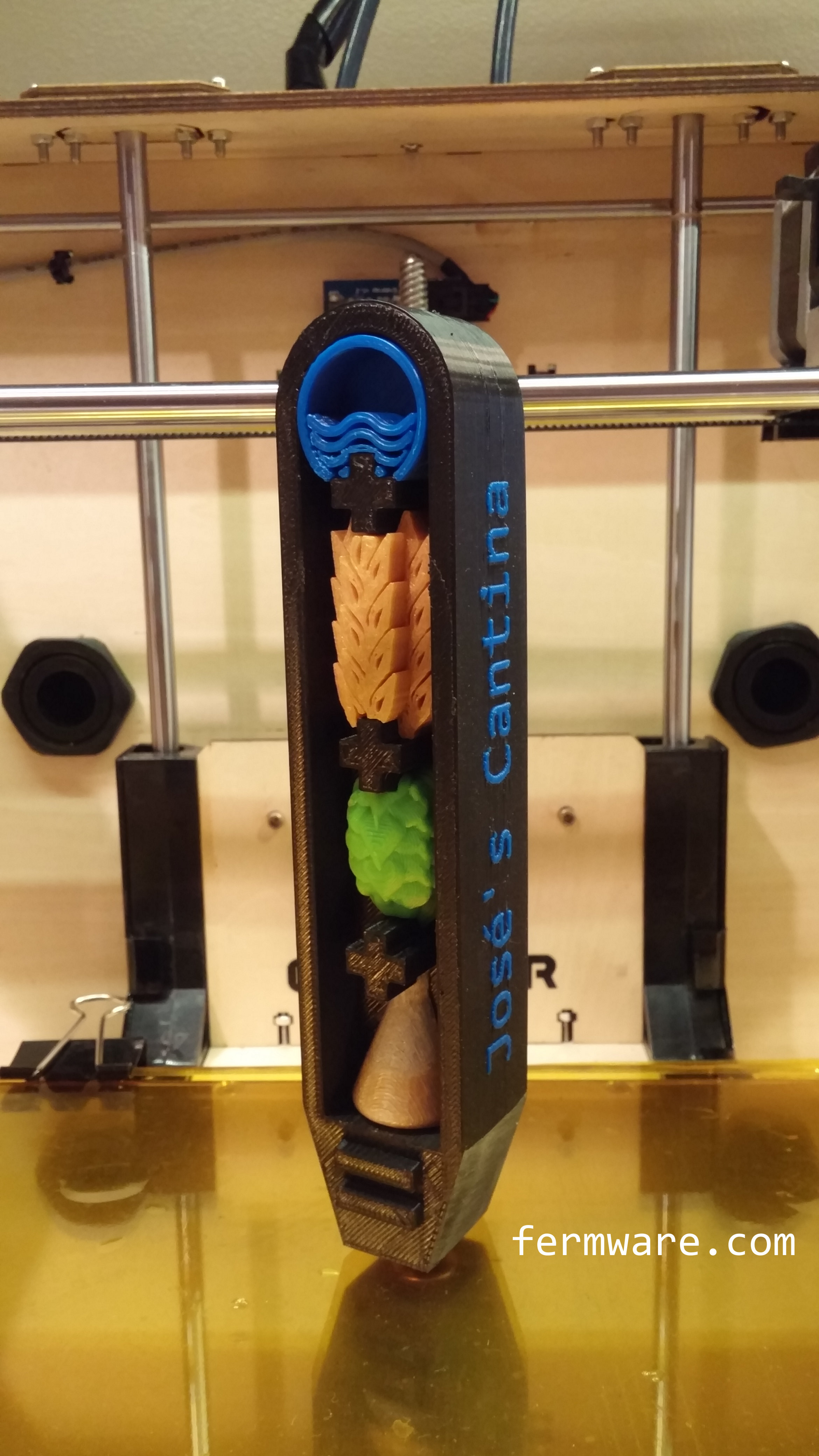

And here are some pictures of a few I did for some members here and elsewhere.

And here are some pictures of a few I did for some members here and elsewhere.

mythbustingpyro

Well-Known Member

I don't have a kegging system so it'd be early for me to be designing tap handles for me too print. Love the modular design too.

Are you running dual extrusion? If not are the letters inserts?

Are you running dual extrusion? If not are the letters inserts?

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

Carlscan26

Well-Known Member

Got mine today. Absolutely freakin awesome!!

I like how you highlighted the arithmetic signs in that second one there - really makes them pop out.

Sent from my iPhone using Home Brew

I like how you highlighted the arithmetic signs in that second one there - really makes them pop out.

Sent from my iPhone using Home Brew

I don't have a kegging system so it'd be early for me to be designing tap handles for me too print. Love the modular design too.

Are you running dual extrusion? If not are the letters inserts?

Yes, dual extrusion for the black handle and the letters. The icons are printed separately and glued in.

Got mine today. Absolutely freakin awesome!!

I like how you highlighted the arithmetic signs in that second one there - really makes them pop out.

Sent from my iPhone using Home Brew

Awesome! Glad to hear you like it.

lawless317

Well-Known Member

- Joined

- Jun 14, 2012

- Messages

- 224

- Reaction score

- 36

I will be buying one of these handles

If they are still for sale

They are awesome and I wanna throw some support

I have been making mine the old fashioned way with wood and metal

If they are still for sale

They are awesome and I wanna throw some support

I have been making mine the old fashioned way with wood and metal

I will be buying one of these handles

If they are still for sale

They are awesome and I wanna throw some support

I have been making mine the old fashioned way with wood and metal

Yes, I think I'll be making them for a while. Check out my link on the first post and let me know. Through the site preferred.

No shame in tried and trusted wood and metal. I made some out of wood and metal too:

https://www.homebrewtalk.com/f252/super-easy-tap-handles-477028/

Pretty soon we'll be looking at 3D printers in the way that we would look at a dot matrix printer now!

Komocabo

Well-Known Member

- Joined

- Oct 16, 2012

- Messages

- 1,083

- Reaction score

- 159

Got mine in today! This thing is awesome.

Size is about 6.5" tall, and 1.25 wide and deep. Fits perfectly on my Kegerator. Well done Eric!

View attachment 1419115690884.jpg

View attachment 1419115700869.jpg

View attachment 1419115711026.jpg

View attachment 1419115721943.jpg

Size is about 6.5" tall, and 1.25 wide and deep. Fits perfectly on my Kegerator. Well done Eric!

View attachment 1419115690884.jpg

View attachment 1419115700869.jpg

View attachment 1419115711026.jpg

View attachment 1419115721943.jpg

Komocabo

Well-Known Member

- Joined

- Oct 16, 2012

- Messages

- 1,083

- Reaction score

- 159

Installed...

I'm glad you like it. The font was a challenge, but I learned a few things getting it to work and I'm happy to have gained some new knowledge.

kev211

Well-Known Member

Im gonna resurrect this thread to ask the OP... Did you find the thread pitch and size online for the typ tap handle? If so, where did you find it/what dimensions did you use? Im gonna be 3D printing my own tap handle and have everything drawn up except the threads.

Im gonna resurrect this thread to ask the OP... Did you find the thread pitch and size online for the typ tap handle? If so, where did you find it/what dimensions did you use? Im gonna be 3D printing my own tap handle and have everything drawn up except the threads.

Sorry I've been late to respond.

The insert is this:

E-Z LOK 260-6-BR (3/8"-16 brass insert)

You can get them at Amazon or McMaster

Go to my Thingiverse "thing" to get more details.

http://www.thingiverse.com/thing:542537

3/8-16 is the standard threading for most faucets.

kev211

Well-Known Member

Sorry I've been late to respond.

The insert is this:

E-Z LOK 260-6-BR (3/8"-16 brass insert)

You can get them at Amazon or McMaster

Go to my Thingiverse "thing" to get more details.

http://www.thingiverse.com/thing:542537

3/8-16 is the standard threading for most faucets.

Ok, so you just inserted the brass piece into the tap handle, the more I thought about it, the more that seemed like the smarter idea. Did you just use an epoxy? Or will any glue work for that? I use cyanoacrylate for gluing the plastic to plastic, but I doubt that would work for brass to plastic

Edit: Nevermind, checked it out on amazon. That thing is pretty cool

These are beautiful. Perhaps a silly question, do the ones people buy have the website printed on both sides? If so, can that be omitted?

I'll print whatever you want on the sides, so yes, I can make a blank handle as well.

Check out the Gallery of 3D Printed Tap Handles for ideas.

Ok, so you just inserted the brass piece into the tap handle, the more I thought about it, the more that seemed like the smarter idea. Did you just use an epoxy? Or will any glue work for that? I use cyanoacrylate for gluing the plastic to plastic, but I doubt that would work for brass to plastic

Edit: Nevermind, checked it out on amazon. That thing is pretty cool

The knurling on the brass "should" be enough to keep the insert in, but since I print in ABS, I use a q-tip to coat the inside of the hole with acetone. Then when I press the insert in, it's got a nice soft surface that really conforms to the knurling. Then you've got a pretty solid fit.

I'll print whatever you want on the sides, so yes, I can make a blank handle as well.

Check out the Gallery of 3D Printed Tap Handles for ideas.

Perfect! I'll be ordering soon.

kev211

Well-Known Member

The knurling on the brass "should" be enough to keep the insert in, but since I print in ABS, I use a q-tip to coat the inside of the hole with acetone. Then when I press the insert in, it's got a nice soft surface that really conforms to the knurling. Then you've got a pretty solid fit.

Gotcha, that seems smart. I just ordered one of the brass inserts so I want to get this thing printing, how deep was the pilot hole that you made? I cant seem to find any dimensions for it on amazon

Gotcha, that seems smart. I just ordered one of the brass inserts so I want to get this thing printing, how deep was the pilot hole that you made? I cant seem to find any dimensions for it on amazon

The insert is 5/8" long. I made the hole 0.650" deep and have had no issues.

That thing is rad! You could sell these things man. I'd be one of the sales

You said rad.

kev211

Well-Known Member

The insert is 5/8" long. I made the hole 0.650" deep and have had no issues.

Perfect thanks

Never thought of doing this. I love my tap handle (camshaft with threading welded on), but I might need a few more soon!

I am going to print this within a week or so. Will post updates when I finish it.

I am going to print this within a week or so. Will post updates when I finish it.

did you consider heating the brass insert before putting it in? That's what we typically do on our 3D printed parts that need brass threading. I never have put a large insert in before, maybe you decided against it since it is so large.

did you consider heating the brass insert before putting it in? That's what we typically do on our 3D printed parts that need brass threading. I never have put a large insert in before, maybe you decided against it since it is so large.

Yes, I definitely considered that option, and the heated insert tool that is made for it, but for the tap handles, the acetone trick and just pressing them in by hand, works just fine.

For small inserts, I'll certainly consider your advice. I just haven't had anything that's needed them yet.

Similar threads

- Replies

- 11

- Views

- 4K

- Replies

- 0

- Views

- 1K

- Replies

- 1

- Views

- 1K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)