FloppyKnockers

Well-Known Member

I've been in search of a keg management system for a while now. Until recently, I've been using the method of when you pull the handle and beer comes out, that means there's still beer in the keg. When no beer comes out, the keg is empty.

Although they would probably be the most accurate, I don't like the idea of in-line flow meters. The ol' ball and magnet thing was a good idea, but way too annoying and cumbersome. The Plaato system came out not too long ago and I really like the idea of it. I just couldn't pull the trigger on $130/scale and I need 3. I ran across a YouTube video of a guy who made a scale out of a piece of plywood and some electronics on the cheap. Not just a little cheap. I mean cheap, cheap. I was intrigued...

More research on the YouTube I found a guy who took the same bits and took a few steps further. Still using the same load cells, HX711 amp, and a NodeMcu, but he 3D printed a housing and added LEDs to the base. My only problem with his design is that the diameter was larger than the keg (and my printer). I have a standard sized kegerator and the kegs fit in there snugly as it is. So... Time to design my own. To the SketchUp!

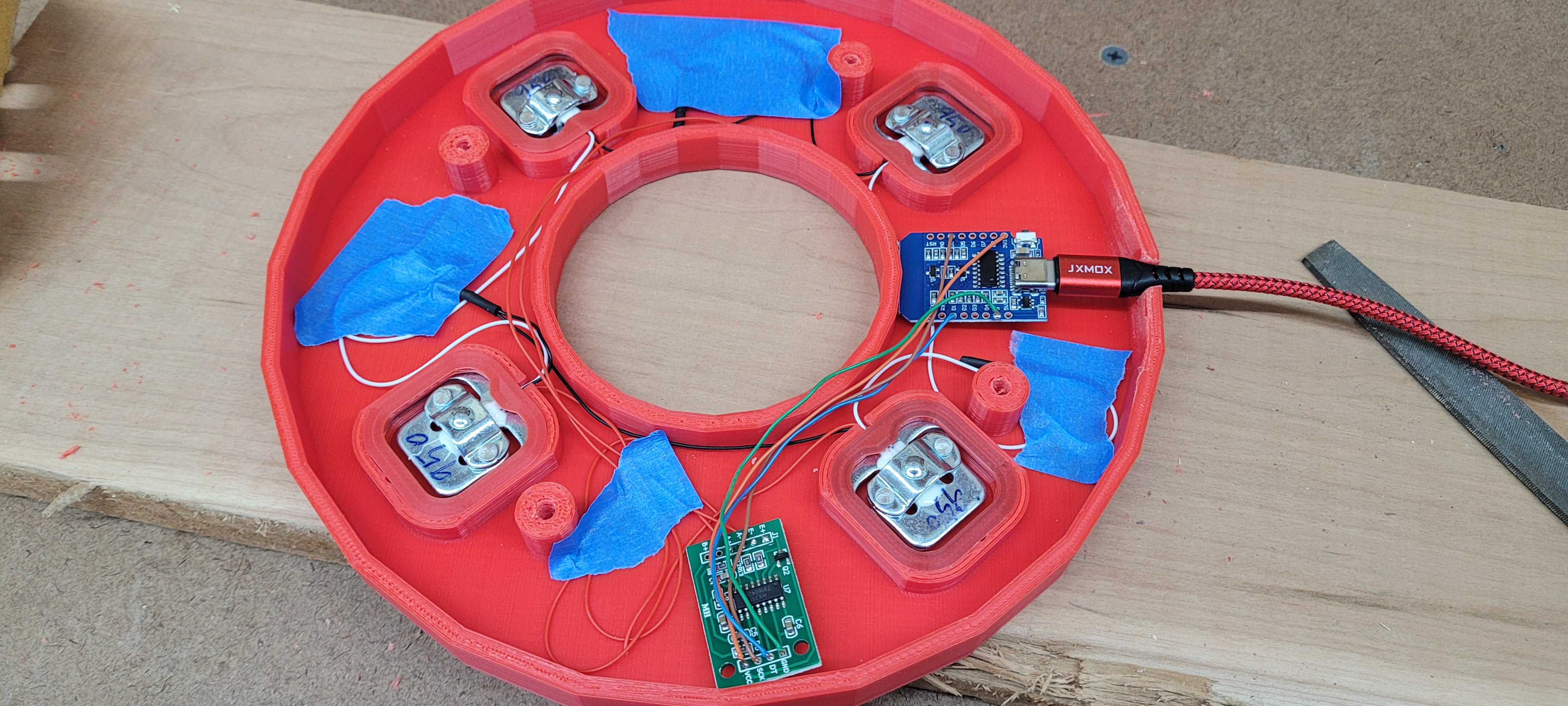

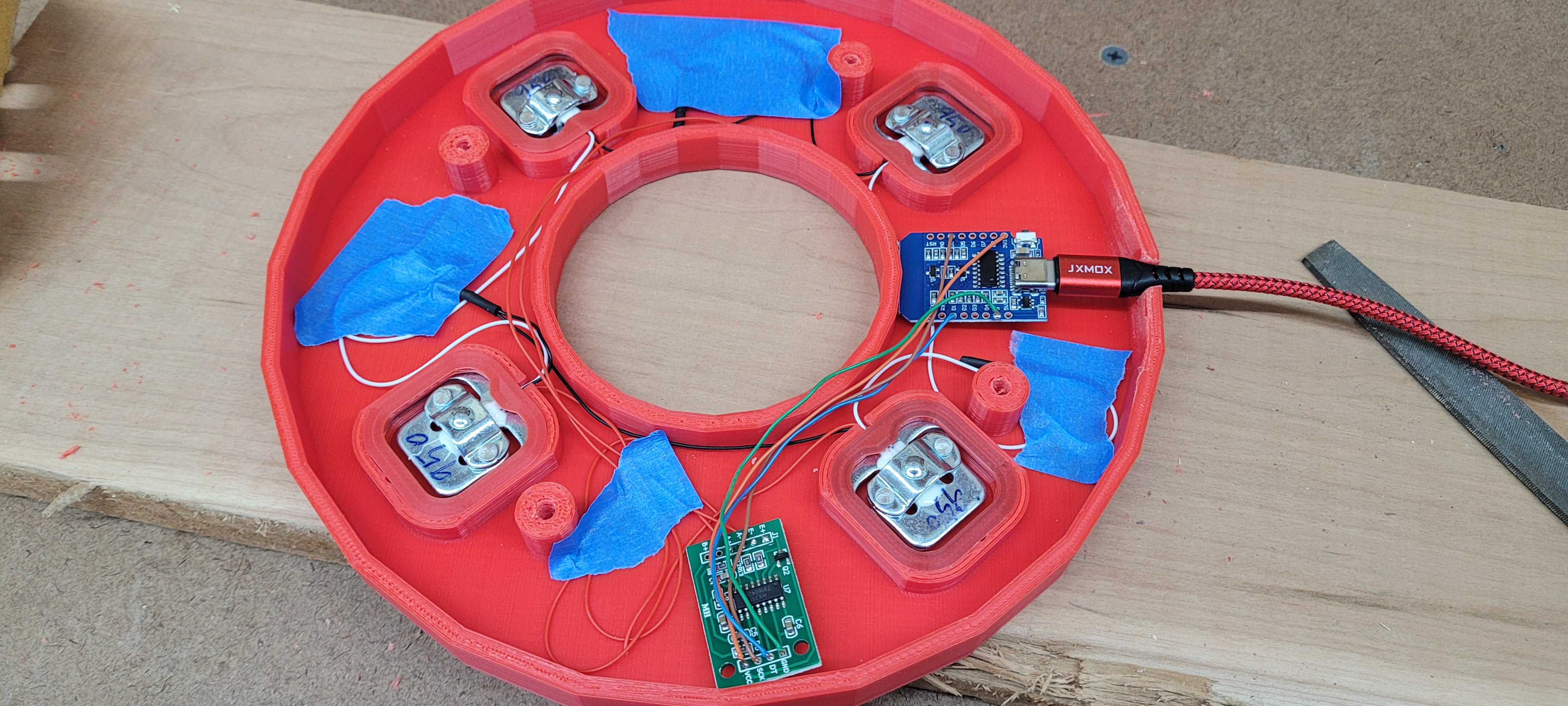

I took the design aspects of the design that I saw and modeled one to suit my needs. I omitted the LED lights because I found them to be an unnecessary accessory. Along with the body, I also made feet and clips to keep the load cells in place.

After the scale was designed, I printed out the first prototype and assembled it.

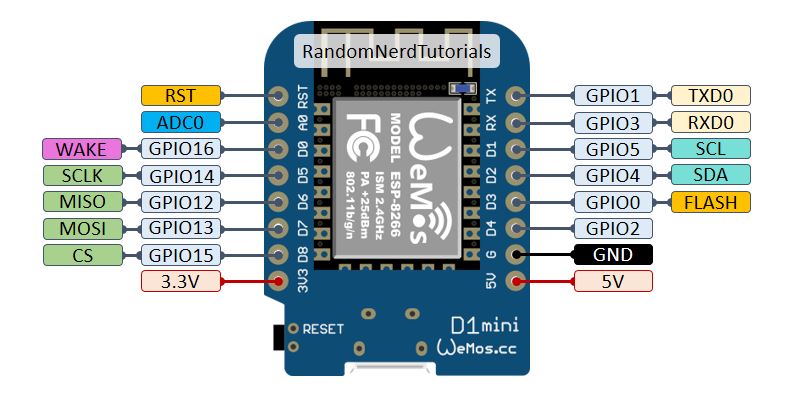

After I had a working model, I printed the first one out and wired it all up. This part was pretty straightforward as there are tons of diagrams, forums, and pages on how to wire the two boards. Some tape to hold the stray wires in place and hot glue to hold the boards.

There ends the "this is going really smooth" part of this build. Now to get the scale to do what I want - display the weight of whatever is on it. Much like the YouTube and other online how-to pages did, I am using HomeAssistant and ESPHome to do all the configuring. First time setting anything like this up.

I had an old Intel NUC so I figured I can run HomeAssistant on that. It wasn't easy, but I managed to get it installed with the help of one of my best friend... YouTube.

Once installed, I had to add ESPHome to configure the scales. Although there are plenty of tutorials out there, I just couldn't get the scales to do anything except say 'HX711 is not ready for new measurements yet' (or something like that). This was extremely frustrating as everywhere I looked, I just couldn't find where to start troubleshooting.

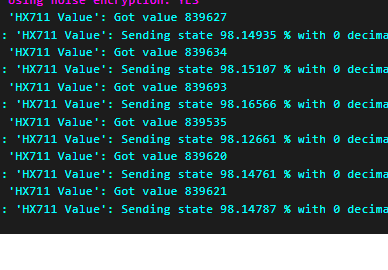

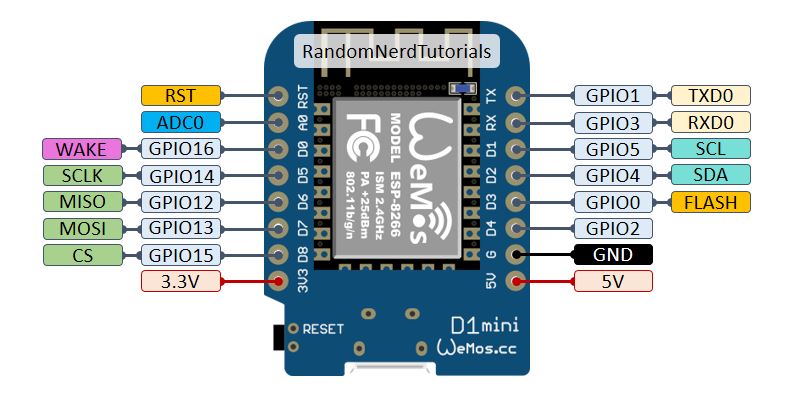

I finally ran across this little gem showing how my NodeMcu should be programmed. Every other reference said to apply the actual name of the pin (eg D5) in ESP Home. This guy says to do something entirely different. Once those values were updated, boom! we have weight values! (This literally took days to find).

Okay, so good. We have one working scale, we know how to program it, should be smooth sailing from here. Well, all up until the extruder gear on your printer decides to wear out in the middle of the night and you think it was just a clog, so you clear it and try again (twice) only to have the same result. It took a hot minute, but I found the problem and ordered a new extruder.

After some calibration and test prints, we're back in business. At about 30 hours printing time per scale, it's time to work on something else.

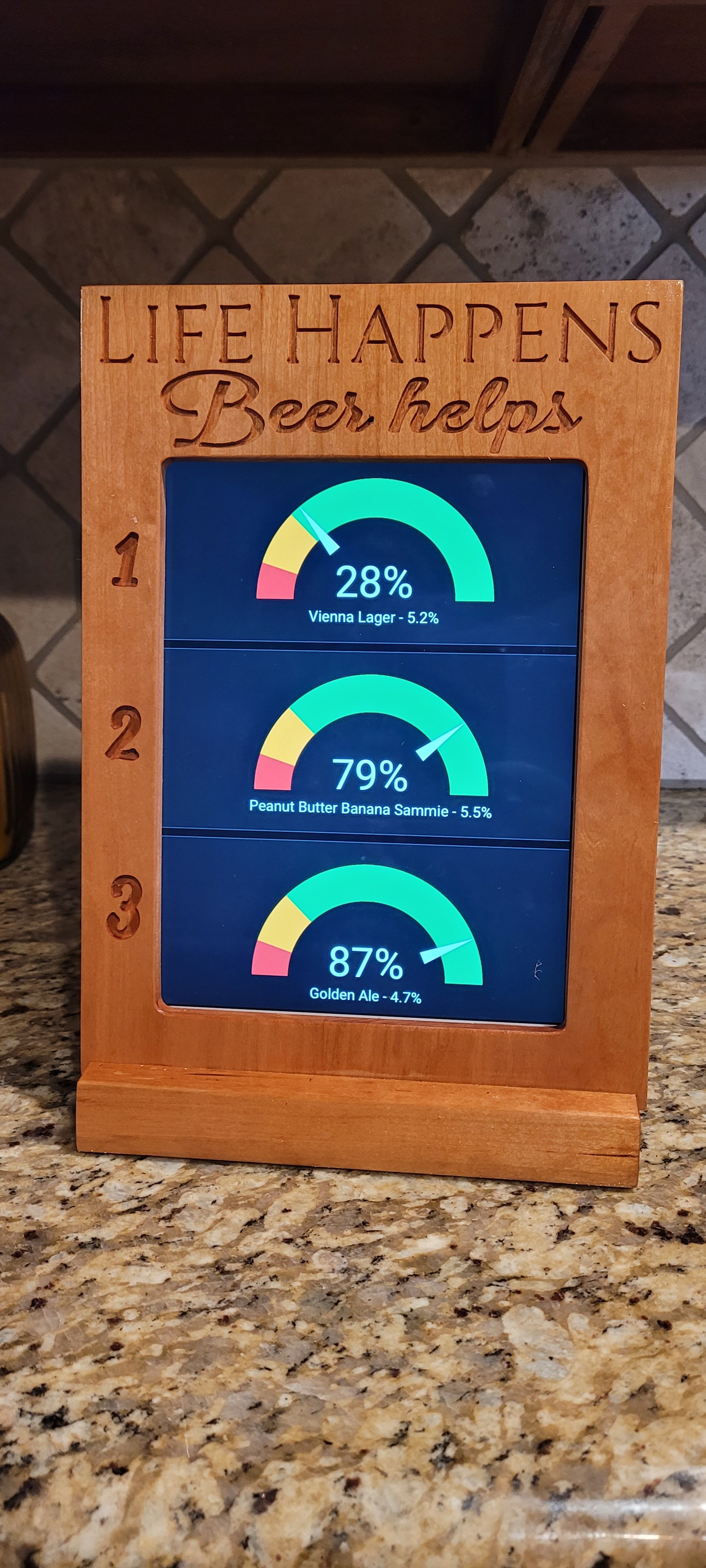

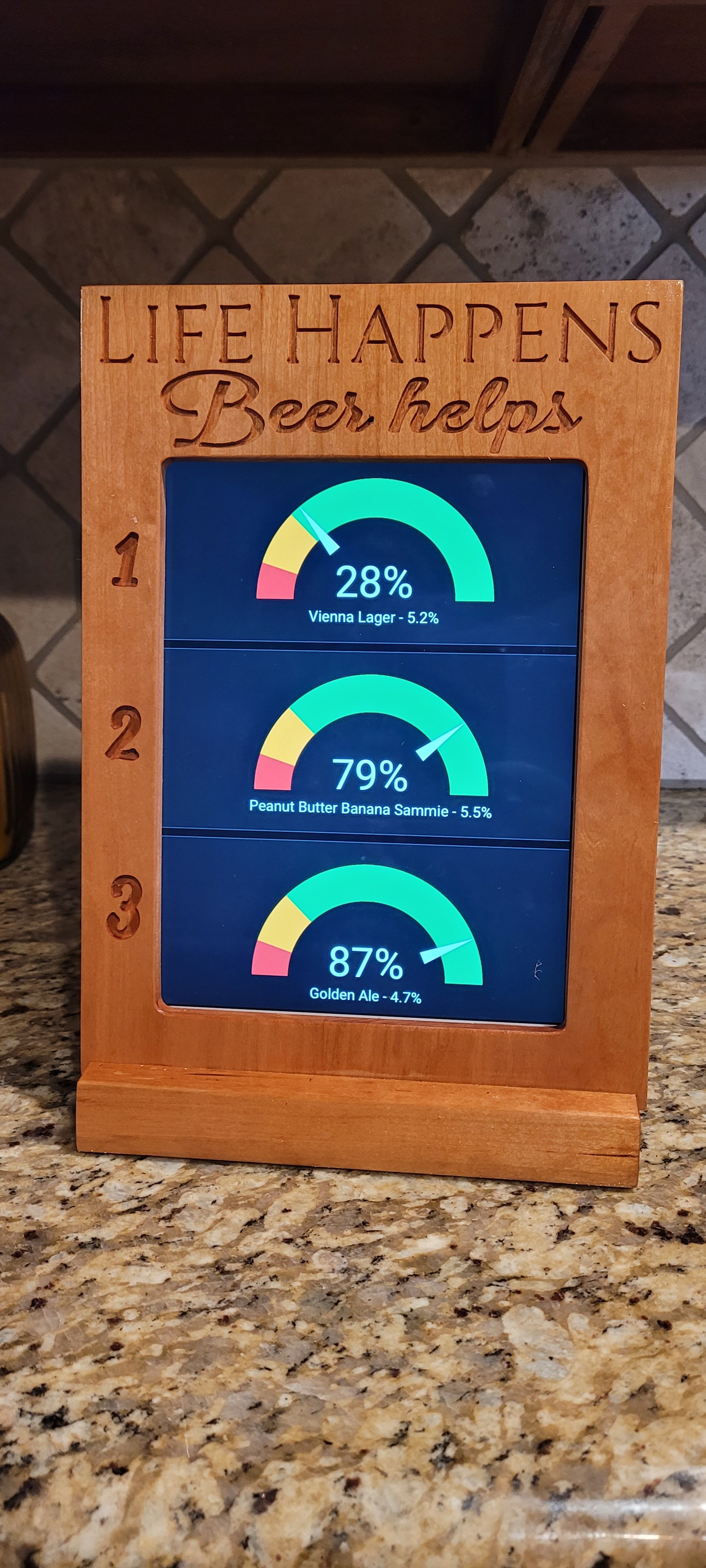

I want a cool way of displaying the kegs so I got an old iPad and installed a kiosk app on it. I set the iPad to never turn off, but set the kiosk app to black the screen after X minutes of inactivity. This way I can just tap the screen and see the kegs.

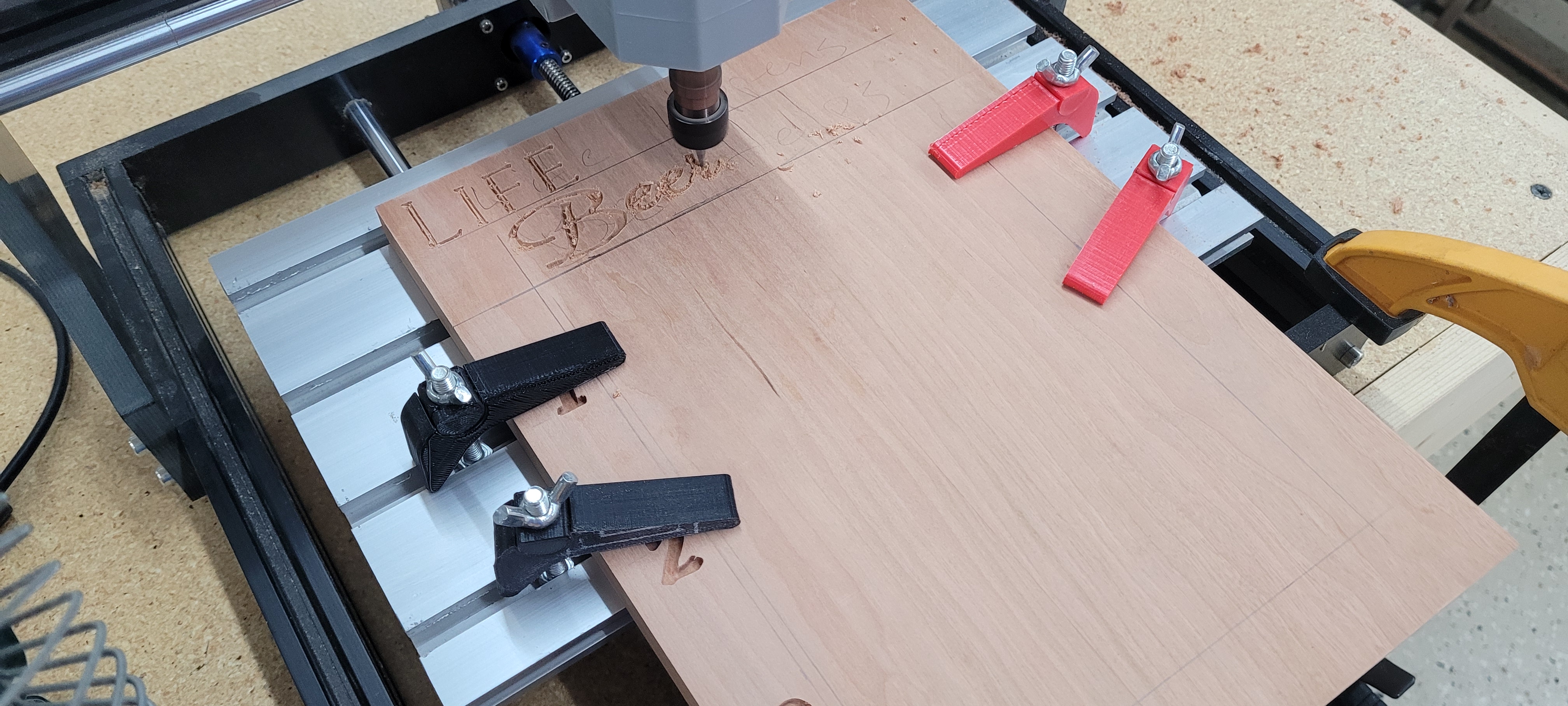

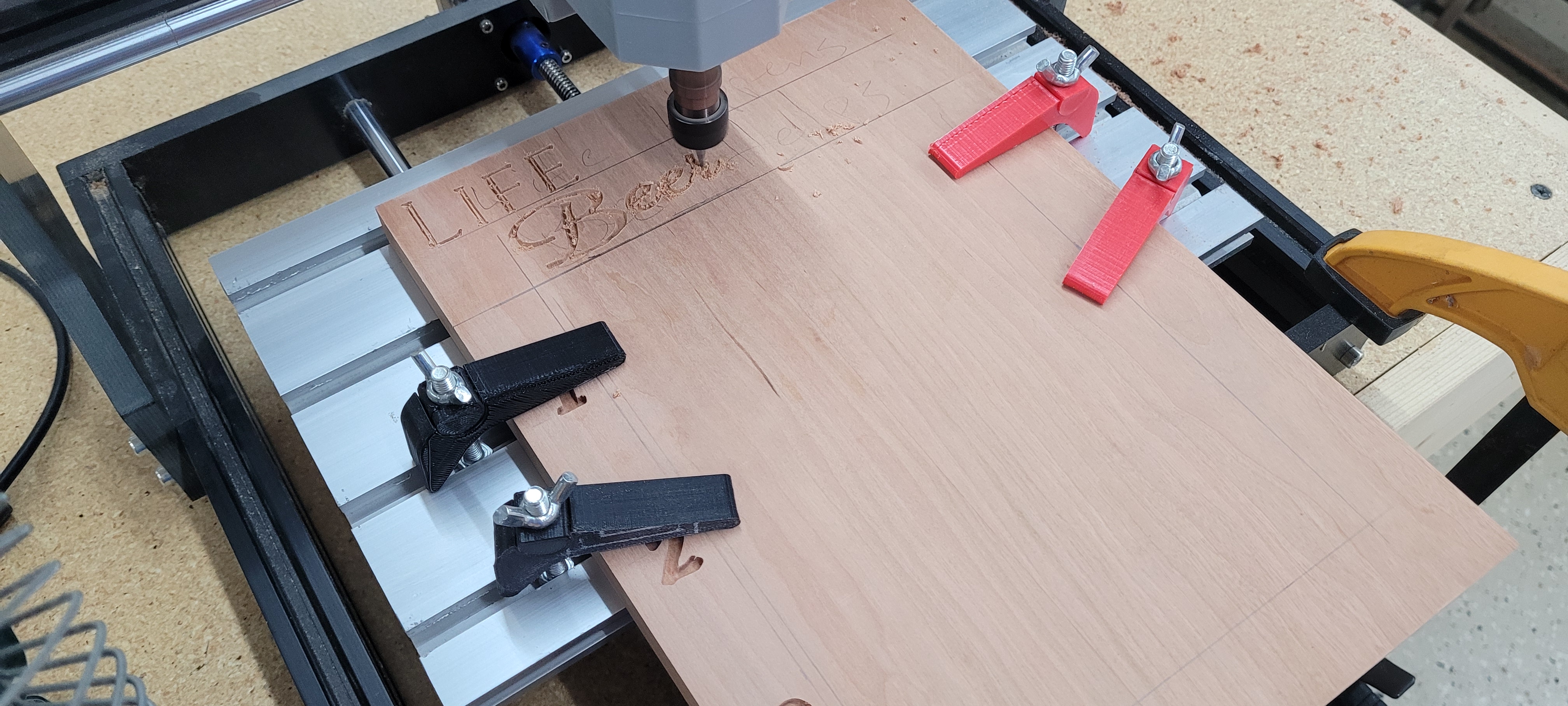

So you just lay the iPad on the counter or something? No way, dude. That would be way too easy. We didn't come this far to have a janky little set-up like that. Off to the CNC router!

I glued up a piece of scrap cherry and planed it down. My router travel is a bit too small to do the whole thing, so I had to break it into segments and route out by hand the opening for the iPad.

A few coats of finish and some fancy cable management later, we have a display!

I made each scale a different color and named them such in ESPHome to make them easier to identify and troubleshoot later on.

Not shown: I ran a USB power hub into the kegerator so I would only have to run one wire out instead of three. Much cleaner, I think.

At the end of the day, I think each scale only cost around $12 not including filament, which would probably only increase the price about $5 or $6 per scale.

Thanks for checking it out and If anyone want to print their own, here's the Thingiverse link.

https://www.thingiverse.com/thing:6007574

Although they would probably be the most accurate, I don't like the idea of in-line flow meters. The ol' ball and magnet thing was a good idea, but way too annoying and cumbersome. The Plaato system came out not too long ago and I really like the idea of it. I just couldn't pull the trigger on $130/scale and I need 3. I ran across a YouTube video of a guy who made a scale out of a piece of plywood and some electronics on the cheap. Not just a little cheap. I mean cheap, cheap. I was intrigued...

More research on the YouTube I found a guy who took the same bits and took a few steps further. Still using the same load cells, HX711 amp, and a NodeMcu, but he 3D printed a housing and added LEDs to the base. My only problem with his design is that the diameter was larger than the keg (and my printer). I have a standard sized kegerator and the kegs fit in there snugly as it is. So... Time to design my own. To the SketchUp!

I took the design aspects of the design that I saw and modeled one to suit my needs. I omitted the LED lights because I found them to be an unnecessary accessory. Along with the body, I also made feet and clips to keep the load cells in place.

After the scale was designed, I printed out the first prototype and assembled it.

After I had a working model, I printed the first one out and wired it all up. This part was pretty straightforward as there are tons of diagrams, forums, and pages on how to wire the two boards. Some tape to hold the stray wires in place and hot glue to hold the boards.

There ends the "this is going really smooth" part of this build. Now to get the scale to do what I want - display the weight of whatever is on it. Much like the YouTube and other online how-to pages did, I am using HomeAssistant and ESPHome to do all the configuring. First time setting anything like this up.

I had an old Intel NUC so I figured I can run HomeAssistant on that. It wasn't easy, but I managed to get it installed with the help of one of my best friend... YouTube.

Once installed, I had to add ESPHome to configure the scales. Although there are plenty of tutorials out there, I just couldn't get the scales to do anything except say 'HX711 is not ready for new measurements yet' (or something like that). This was extremely frustrating as everywhere I looked, I just couldn't find where to start troubleshooting.

I finally ran across this little gem showing how my NodeMcu should be programmed. Every other reference said to apply the actual name of the pin (eg D5) in ESP Home. This guy says to do something entirely different. Once those values were updated, boom! we have weight values! (This literally took days to find).

Okay, so good. We have one working scale, we know how to program it, should be smooth sailing from here. Well, all up until the extruder gear on your printer decides to wear out in the middle of the night and you think it was just a clog, so you clear it and try again (twice) only to have the same result. It took a hot minute, but I found the problem and ordered a new extruder.

After some calibration and test prints, we're back in business. At about 30 hours printing time per scale, it's time to work on something else.

I want a cool way of displaying the kegs so I got an old iPad and installed a kiosk app on it. I set the iPad to never turn off, but set the kiosk app to black the screen after X minutes of inactivity. This way I can just tap the screen and see the kegs.

So you just lay the iPad on the counter or something? No way, dude. That would be way too easy. We didn't come this far to have a janky little set-up like that. Off to the CNC router!

I glued up a piece of scrap cherry and planed it down. My router travel is a bit too small to do the whole thing, so I had to break it into segments and route out by hand the opening for the iPad.

A few coats of finish and some fancy cable management later, we have a display!

I made each scale a different color and named them such in ESPHome to make them easier to identify and troubleshoot later on.

Not shown: I ran a USB power hub into the kegerator so I would only have to run one wire out instead of three. Much cleaner, I think.

At the end of the day, I think each scale only cost around $12 not including filament, which would probably only increase the price about $5 or $6 per scale.

Thanks for checking it out and If anyone want to print their own, here's the Thingiverse link.

https://www.thingiverse.com/thing:6007574