Hi All,

I am trying to plan my control panel build around the 3BBL Stout Electric Kettles and I have been reading a ton of threads around the subject. I seem to have found several designs but none seem to fit my specific needs and have a few unanswered questions. My building has 208v 3 phase power. I want to power 3 208v 5500 watt elements at a time. (3 in HLT and 3 in BK)

The kettles come with 4 Element Ports but I was going to try and get away with just 3 5500 watt elements since the main breaker may not have room for anything larger than 60A. Correct me if I am wrong, but rough math says losing the 4th 5500W element will only add 10 minutes to reach a boil from 160f. I am ok with an extra 10 minutes if it simplifies my build in cost.

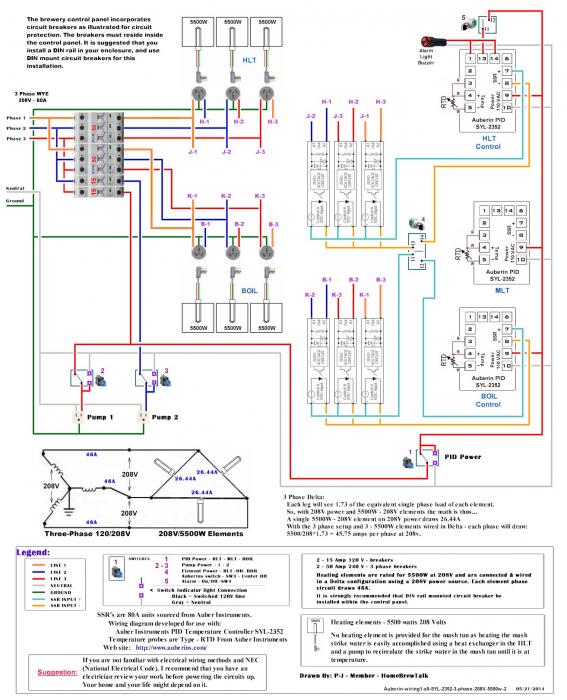

PJ on here has been a wealth of knowledge and he drew up this diagram below for another member.

So here is my question: I figure that the only difference between this design and what I need is just 60a 208V DIN Breakers as opposed to 50a 240V Breakers.. Can anyone confirm this? And can you also confirm that every other aspect if this design would fit my need?

http://www.pjmuth.org/beerstuff/images/Auberin-wiring1-a9-SYL-2352-3-phase-240V-delta.jpg

I am trying to plan my control panel build around the 3BBL Stout Electric Kettles and I have been reading a ton of threads around the subject. I seem to have found several designs but none seem to fit my specific needs and have a few unanswered questions. My building has 208v 3 phase power. I want to power 3 208v 5500 watt elements at a time. (3 in HLT and 3 in BK)

The kettles come with 4 Element Ports but I was going to try and get away with just 3 5500 watt elements since the main breaker may not have room for anything larger than 60A. Correct me if I am wrong, but rough math says losing the 4th 5500W element will only add 10 minutes to reach a boil from 160f. I am ok with an extra 10 minutes if it simplifies my build in cost.

PJ on here has been a wealth of knowledge and he drew up this diagram below for another member.

So here is my question: I figure that the only difference between this design and what I need is just 60a 208V DIN Breakers as opposed to 50a 240V Breakers.. Can anyone confirm this? And can you also confirm that every other aspect if this design would fit my need?

http://www.pjmuth.org/beerstuff/images/Auberin-wiring1-a9-SYL-2352-3-phase-240V-delta.jpg

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)