When I ordered my BIAC, I voiced my concern about doing smaller 5 gallon batches to Nathan and he assured my that it can be done if careful. I wanted to purchase a shorter heating element from him, but he recommended that I bend down the one that comes with the BIAC and see how it goes. He said to leave the heating element installed and reach down into the kettle and push it down. I think that by bending the heating element, keeping the re-circulation rate low, and doing 6 gallon batches should keep me safe. When I raise the colander up, I will leave the heating element off until I'm sure the element is covered. I will monitor the first several batches carefully to make sure I don't ruin the element.

One thing that helps is opening up the gap on your mill from the "normal" .035in to closer to .050in. (an old DVD is a good way to get a even gap around .048in). The last batch I did was 50/50 2-row and wheat and I didn't have any re-circulation problems even with that much wheat. There are a few threads elsewhere that talk about the other benefits of a larger crush when doing a recirculating mash.

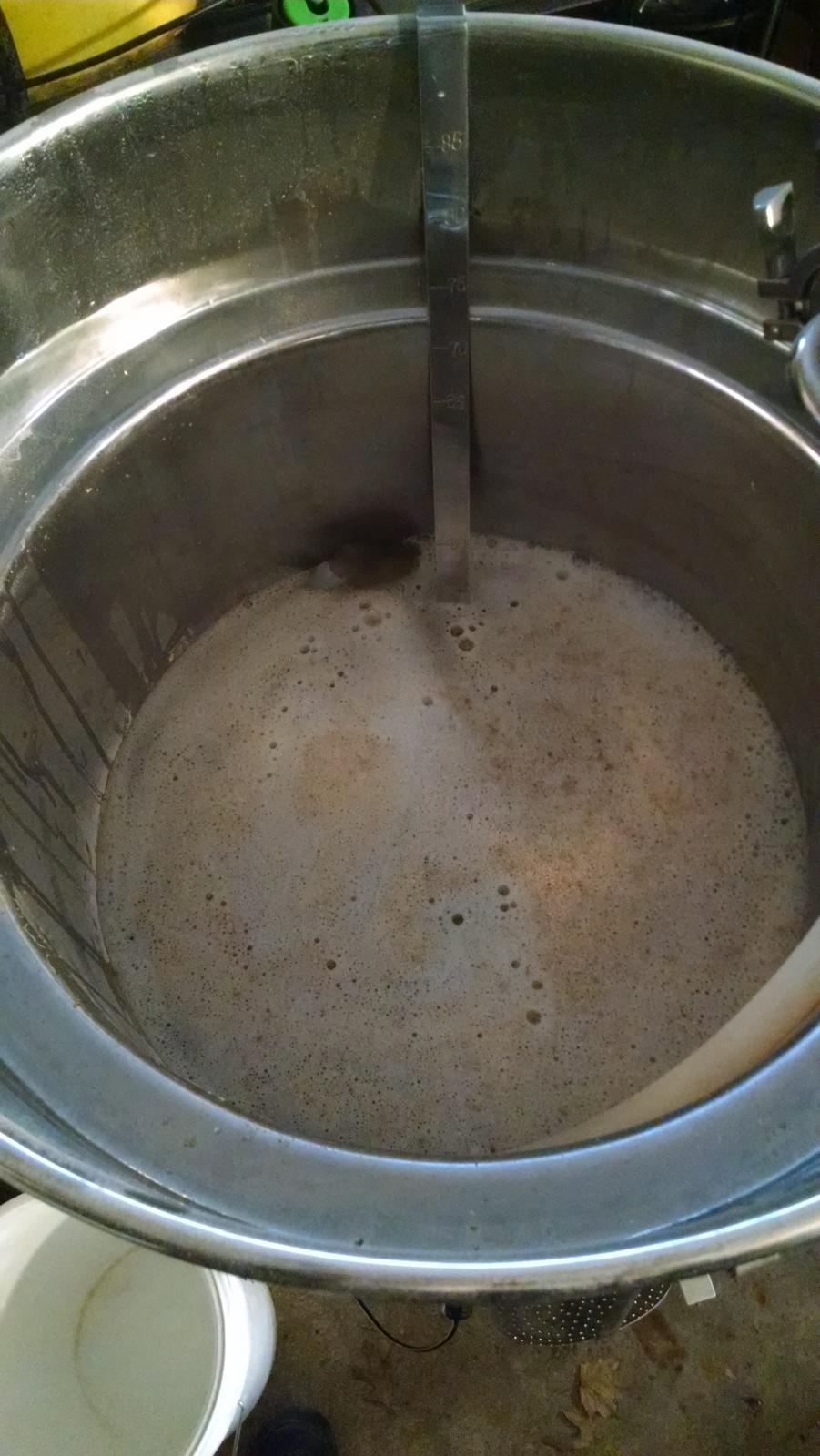

As a safeguard you can also attach a section of tubing to the re-circulation port to create a temporary site glass. I use one of the tri-clamp fitting with the 90deg hose barb and then run the tube up and through a handle at the top. Then, when you're filling the tank with water just mark the tube with a piece of tape when the water level gets above the element. Keep the water above the tape and you're good.

As some point I'll probably etch some markings in the mash colander to make it easier to eyeball without the tube but so far the tube has been easy enough.