1. Using a Mash tun gott style cooler- why don't I see more people installing a weldless thermometer?

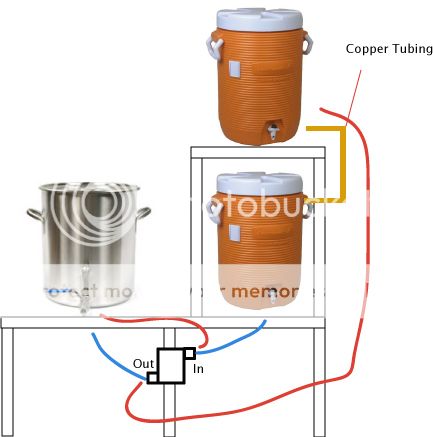

2. Using a Gott style cooler as a HLT and how well does it work for this purpose? I was thinking of doing this to save me money.

2. Using a Gott style cooler as a HLT and how well does it work for this purpose? I was thinking of doing this to save me money.