Back to the topic of the thread...I brewed a 1 gal BIAB batch today. This was a Single Grain Pale Ale made with Pilsner malt. I guess when I am not juggling 2 batches at once (and I skipped messing with pH readings) it is a little more calm.

Milled my grains...2 lbs Pilsner and 1.2 oz Acidulated Malt. (so technically not a single grain batch??)

I used my el-cheapo 3 gal stainless pot I got from Walmart for less than $10. This one:

https://www.walmart.com/ip/Mainstays-Stainless-Steel-12-Quart-Stockpot-with-Lid/37320202 I am using a $10 straining bag that I got years ago to line my bucket lauter tun, but it seems like a good fit for this pot. I have a large mesh bag that is sold for steeping grain or hops that would probably work well too.

I guess I did not take any pics, but I decided to try using my oven to hold the mash temp. I preheated my oven to 170F (the lowest setting) then killed the heat before putting in the pot. I figured opening the door would let out a reasonable amount of heat, but I don't have a good way to check the oven temp. I stirred at 30 min, then after 60 minutes it was a reasonable 148.4F.

Drained in a colander over the top of the pot and squeezed out some of the liquid using a spoon. (For 2.5 gal batches I set this colander over a 5 gal bucket.)

Here I am adding the 10 min hop charge (and Irish Moss). This 3 gal pot has lots of room for both the mash and boiling.

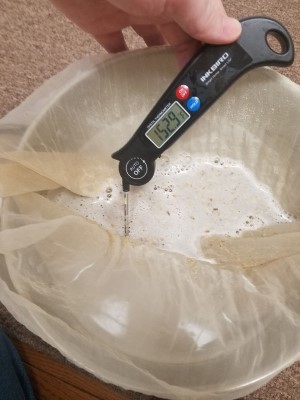

Chilled in an ice bath down to 70F. A tip that has worked well for me is to add cool tap water to bring the temp down to 160F, then drain off that warm water and refill with cool tap water with ice. This wastes a little water but uses a lot less ice.

The beer is in my fermenter in my lower level. These are some containers from Walmart that I drilled for a spigot and bung. On one hand I love this fermenter, but on the other hand I have had issues with getting a good seal at the spigot and tension tightening the spigot causing the hard plastic to crack. For the price and effort, I would just get a glass Little Big Mouth Bubbler. Another option is to just not add a spigot, but I like the ease of bottling from the fermenter with the spigot.

I came in just below my target gravity, but I also had to dump some wort to give some headspace in my fermenter. I tweaked some settings in BeerSmith to bring the strike water volume down from 1.7 to 1.6 gals. I probably hit around 65% efficiency.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)