sam

Well-Known Member

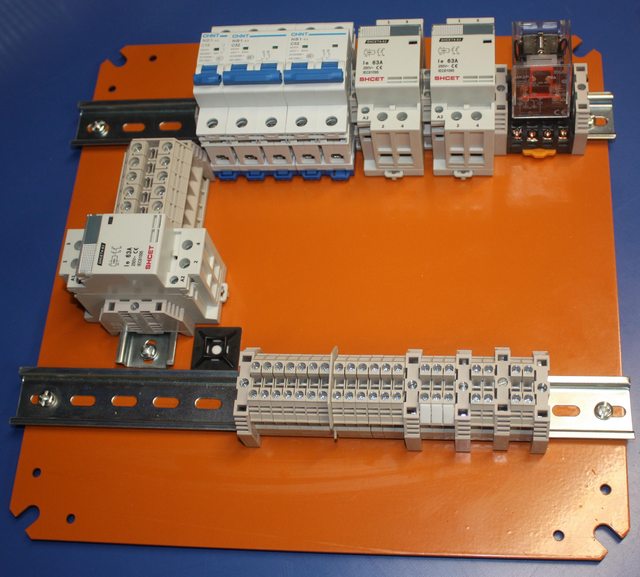

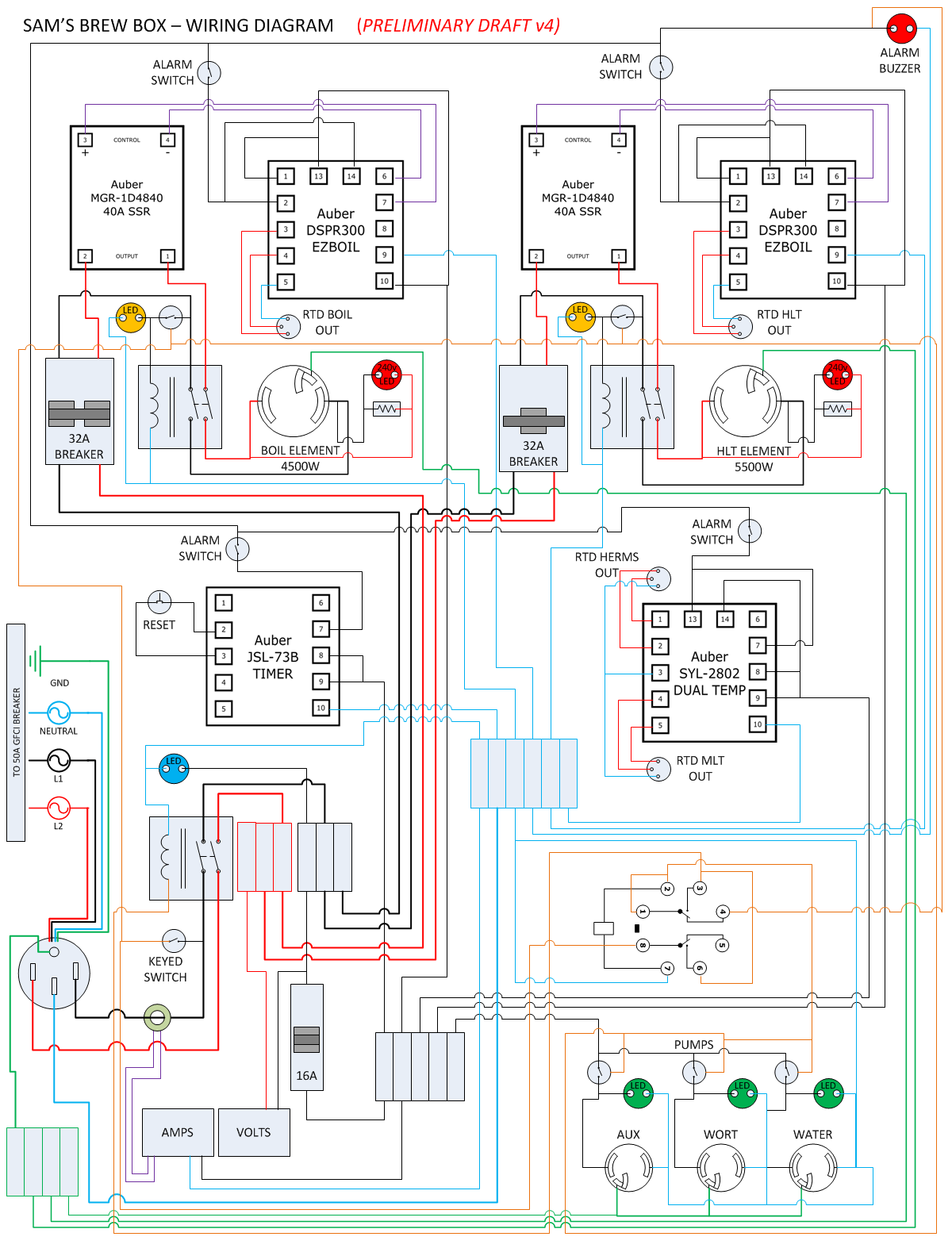

I'm ready for a new project! I've found myself spending more and more time reading threads about electric brewing and have been inspired by the builds here. Time to pull the trigger and convert my old single-tier direct fired mash system. I brew in fits and starts and I'm hoping that converting over to electric and bringing it inside will allow me to brew more regularly.

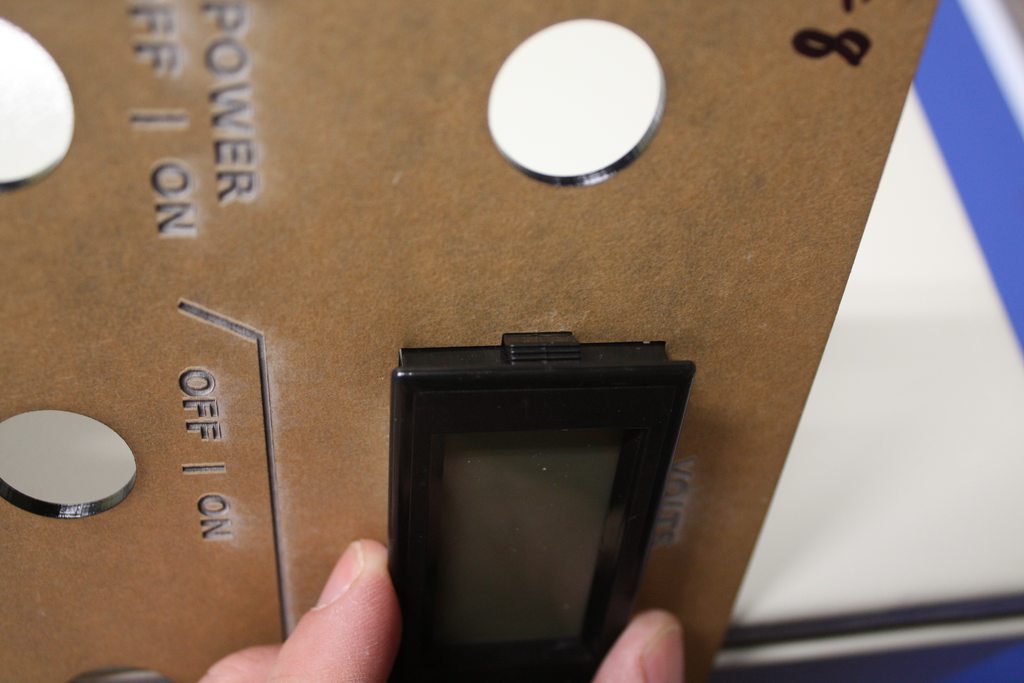

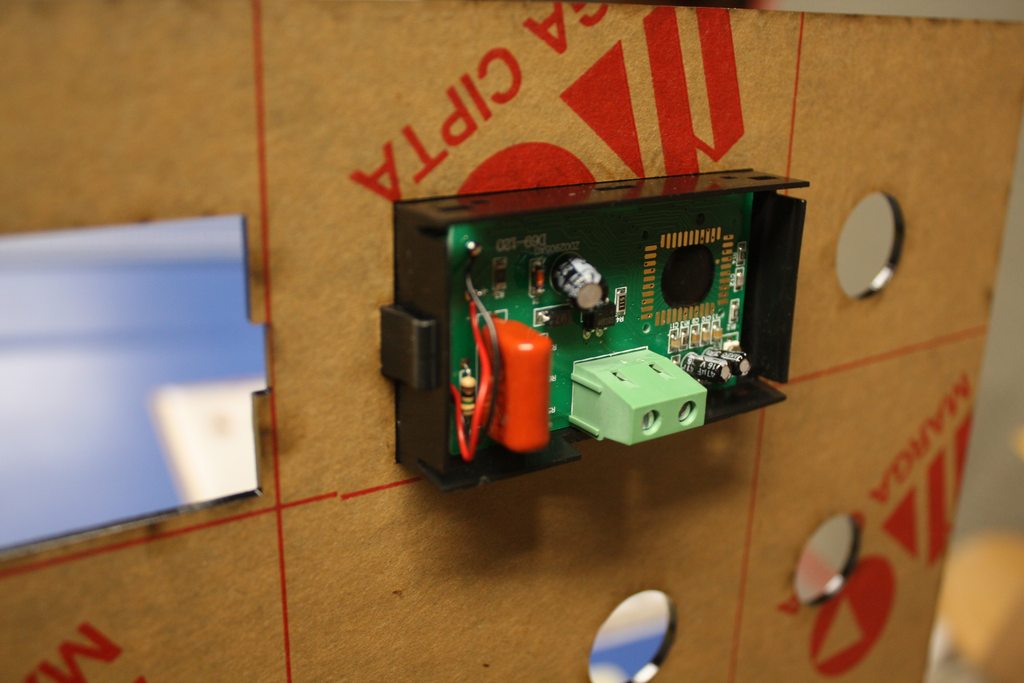

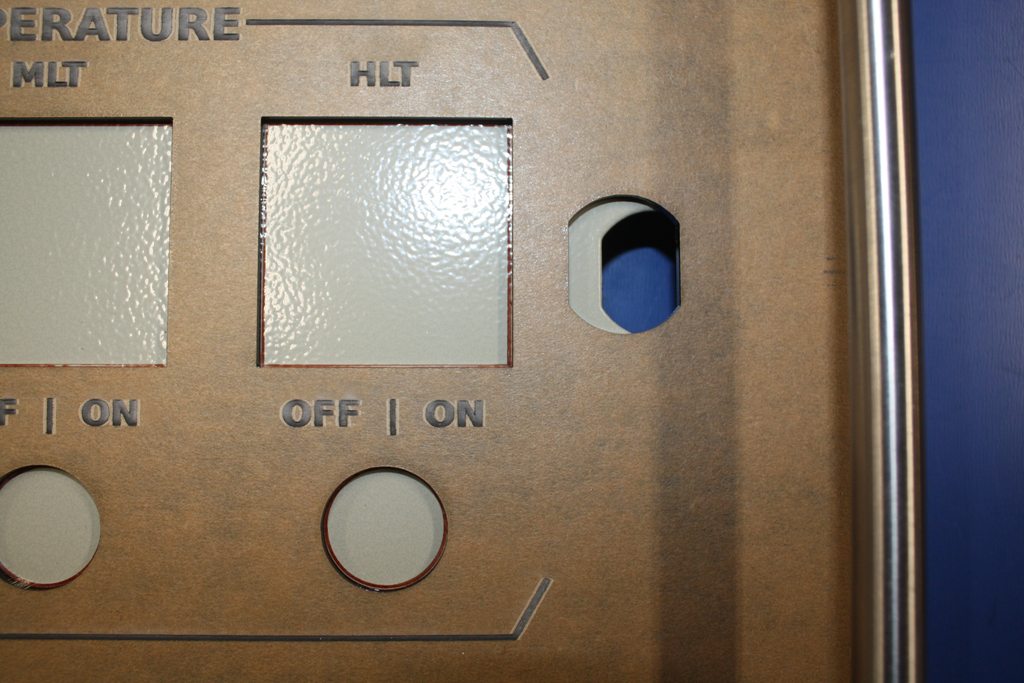

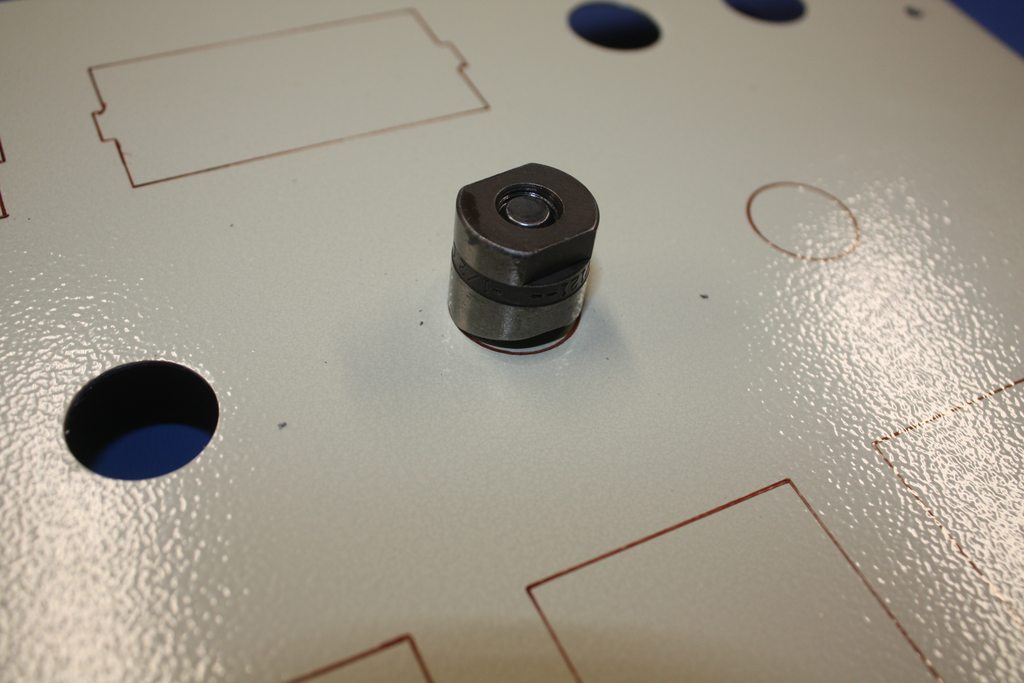

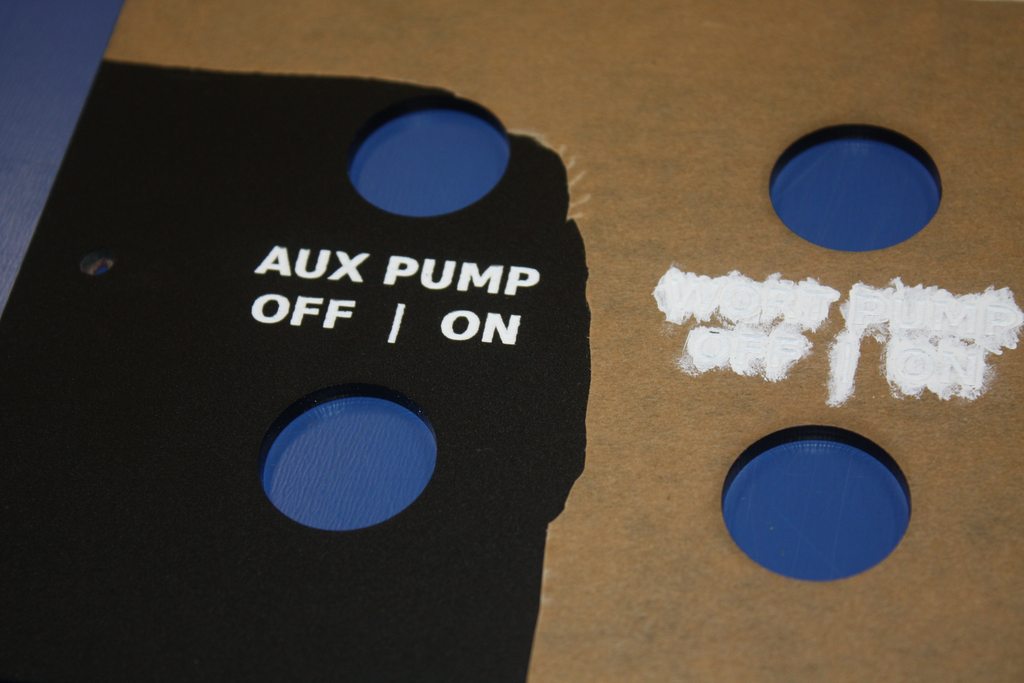

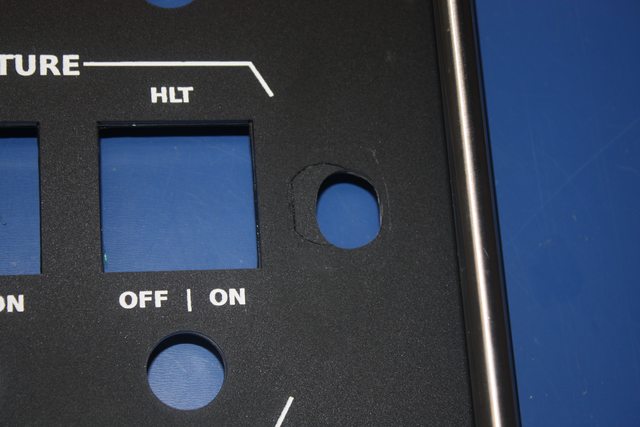

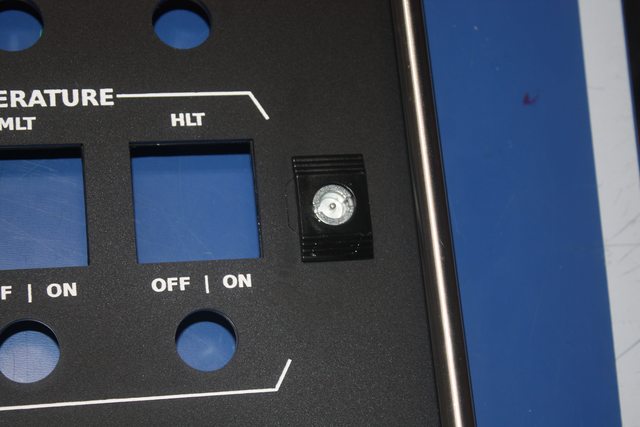

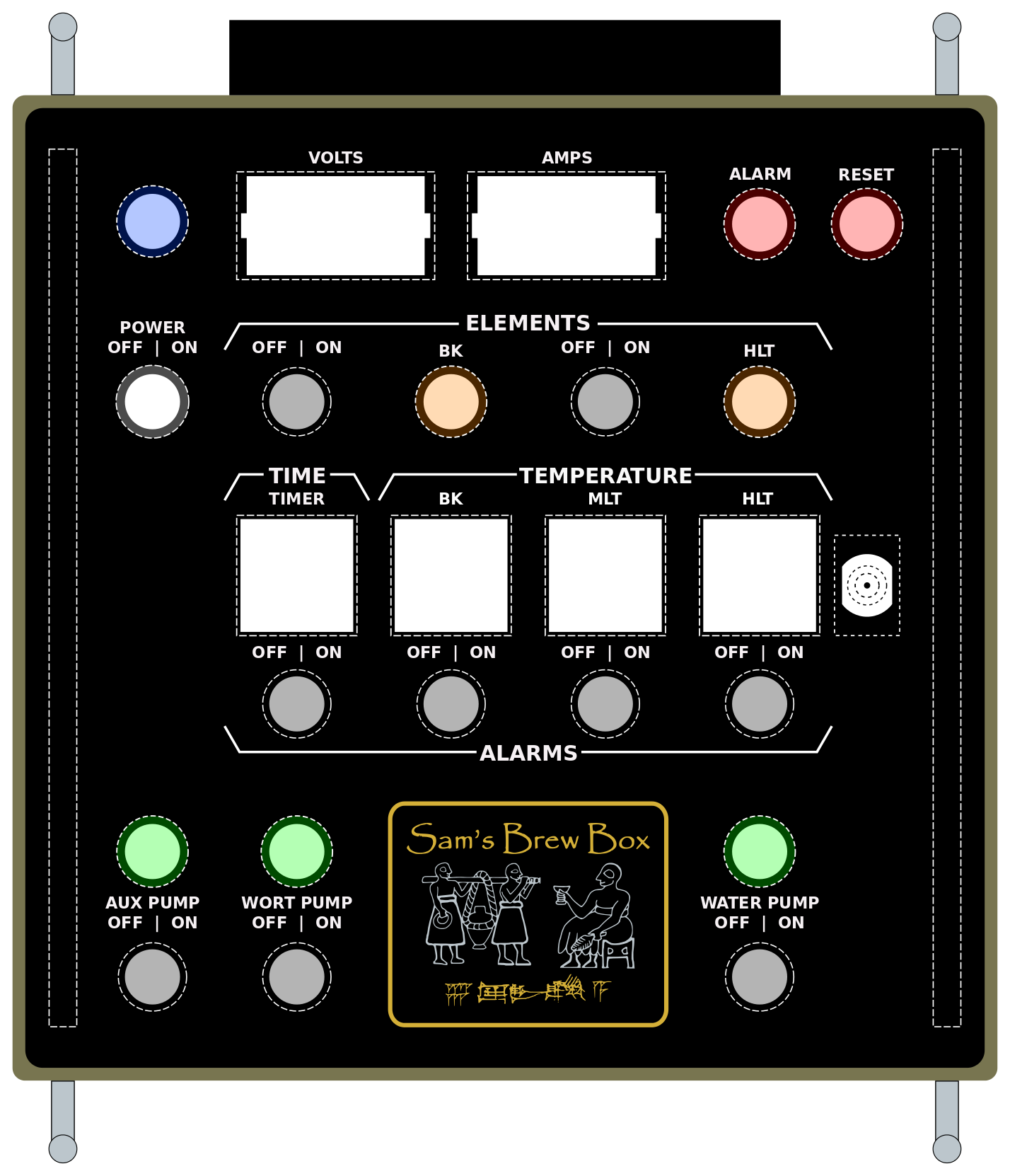

I purchased Kal's guide a while ago and have been sourcing the parts myself; planning on a 50A back-to-back setup with an extra pump. One thing I wasn't too keen on was the look of the panel tags. I came across ponoko.com and decided to have a piece of acrylic cut and engraved. Below is layout I came up with.

I used Inkscape to design the layout and posted the file here in case anyone wants to use it.

The ponoko formatted files can be found here and can also be used freely.

I purchased Kal's guide a while ago and have been sourcing the parts myself; planning on a 50A back-to-back setup with an extra pump. One thing I wasn't too keen on was the look of the panel tags. I came across ponoko.com and decided to have a piece of acrylic cut and engraved. Below is layout I came up with.

I used Inkscape to design the layout and posted the file here in case anyone wants to use it.

The ponoko formatted files can be found here and can also be used freely.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)