The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Ok, thanks for that bit of info. One way or another, I was planning on keeping the bag off the element. With the stainless basket that's a given.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

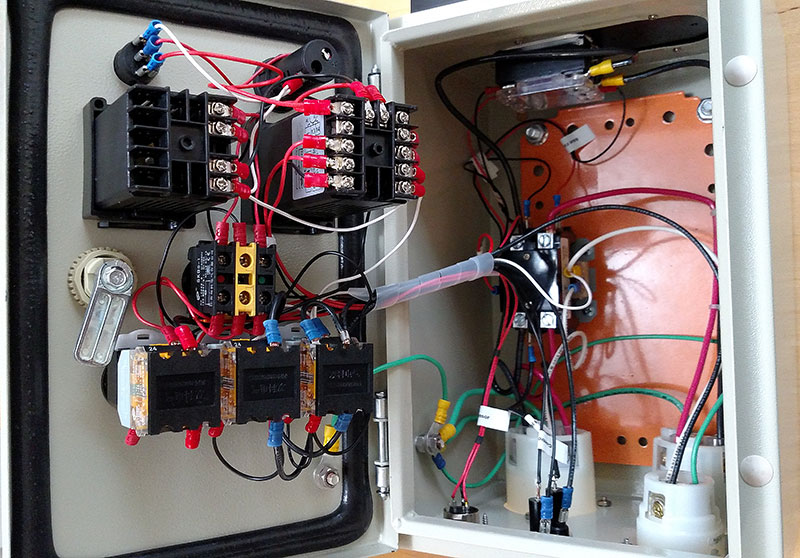

What a great (clean) controller! At some point I am sure that I will rebuild my $6 harbor freight ammo box controller and will be looking at your design for ideas.Everything's mocked up, so far it looks good.

Should be a fun and busy weekend.Basket and power cord came in! All I need to do is install the outlet, do a little re-arranging of my brew stand, and it's off to the races (or testing, as the case may be).