- Joined

- Jan 14, 2015

- Messages

- 1,101

- Reaction score

- 316

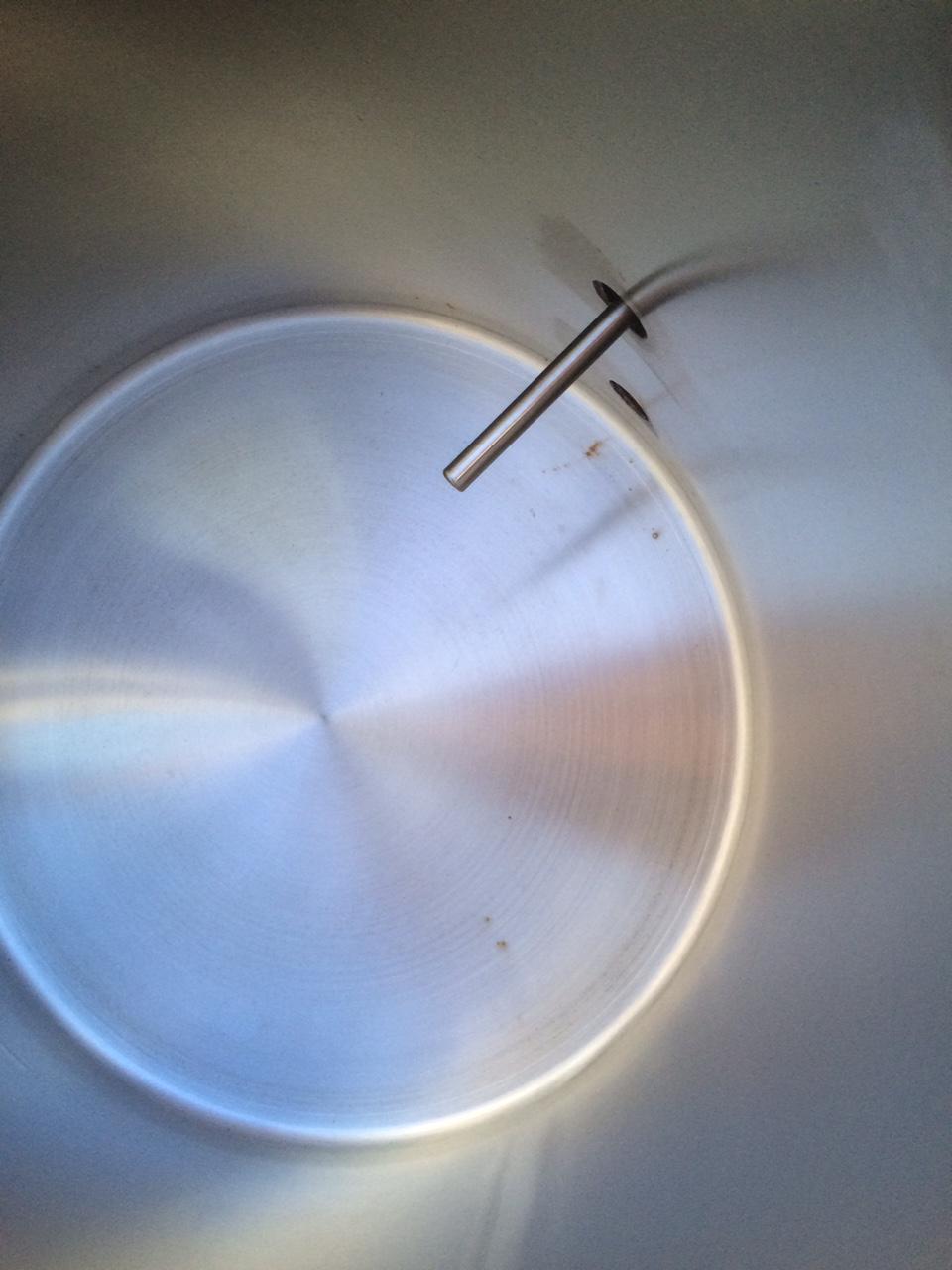

Has anyone else had any problems with their boil kettle draining?

Basically I installed a street 90 inside mine today to act like a dip tube, and when I went to drain it, it slowed to a trickle and then stopped as soon as it met where the street 90 attached to the inside of the welded on coupler.

If I tilted the kettle so the water covered the connection it would start to drain again.

Basically I installed a street 90 inside mine today to act like a dip tube, and when I went to drain it, it slowed to a trickle and then stopped as soon as it met where the street 90 attached to the inside of the welded on coupler.

If I tilted the kettle so the water covered the connection it would start to drain again.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)