Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

True, but credit where it's due - it's a nice DIY rig if you're NOT doing LODO!

It absolutely is. It was just funny in the context.

True, but credit where it's due - it's a nice DIY rig if you're NOT doing LODO!

i'm curious of what you are doing and why...got an illustration of this ?I mash in a 10 gal cooler and I'm purchasing a RIMS package from brewhardware.

I'm using a floating stainless pizza pan as the mash cap. There's only about 3/4" clearance between the mash cap and the wall of the cooler.

I'm wondering what's the best way to set up the wort return to avoid aeration and also avoid wrecking the grain bed?

It needs to drop about 5-8" into the mash tun for my regular size batches.

Some kind of Loc-Line with an elbow to direct the incoming wort sideways?

A couple elbows top so it can just rest on the rim of the cooler/tun?

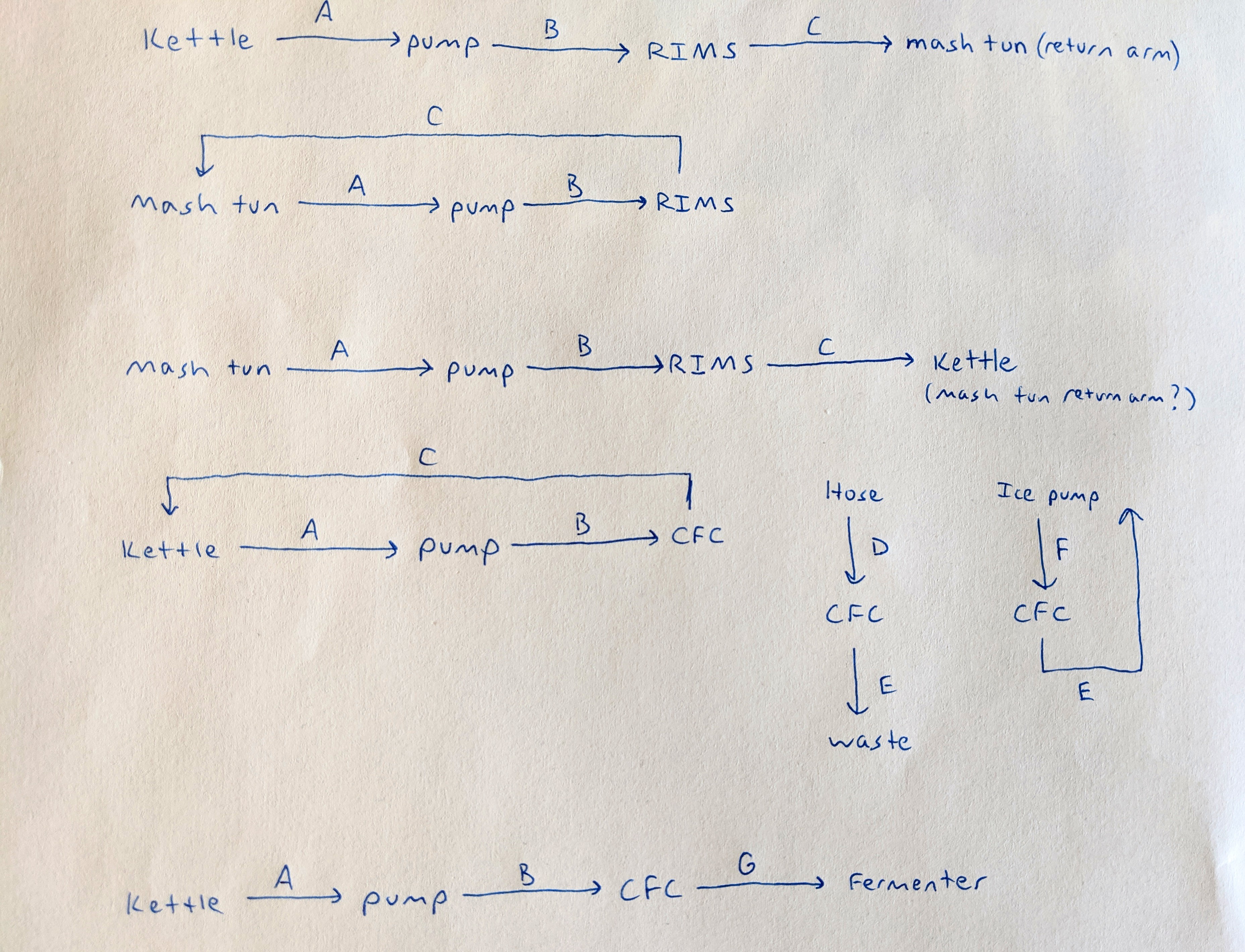

As a matter of fact, I do. This was my plan as I was picking out all my new fittings (I'm upgrading to all 1/2" tubing with ball-lock quick connects).i'm curious of what you are doing and why...got an illustration of this ?

As a matter of fact, I do. This was my plan as I was picking out all my new fittings (I'm upgrading to all 1/2" tubing with ball-lock quick connects).

My brew day has 7 flow paths. It'll be single tier with no gravity transfers.

In order:

- Transfer water from kettle (being used as HLT) to the mash tun.

- Recirculate the mash through the RIMS.

- Transfer the wort to the kettle.

- Recirculate wort through the CFC to chill.

- Ground water chilling phase.

- Ice water recirculation chilling phase.

- Transfer chilled wort from kettle to fermenter.

Hoses are labeled with letters.

View attachment 639366

As to the "why" ... This is the Low Oxygen Brewing subforum. By eliminating oxygen on both the hot side and cold side we can make beer with amazing flavor.

My RIMS needs to return the wort under the surface so there's no splashing/aeration.

Cheers

I still dont get the LODO thing. I mean I understand what youre trying to do but it still seems like a lot of counterproductive steps .As a matter of fact, I do. This was my plan as I was picking out all my new fittings (I'm upgrading to all 1/2" tubing with ball-lock quick connects).

My brew day has 7 flow paths. It'll be single tier with no gravity transfers.

In order:

- Transfer water from kettle (being used as HLT) to the mash tun.

- Recirculate the mash through the RIMS.

- Transfer the wort to the kettle.

- Recirculate wort through the CFC to chill.

- Ground water chilling phase.

- Ice water recirculation chilling phase.

- Transfer chilled wort from kettle to fermenter.

Hoses are labeled with letters.

View attachment 639366

As to the "why" ... This is the Low Oxygen Brewing subforum. By eliminating oxygen on both the hot side and cold side we can make beer with amazing flavor.

My RIMS needs to return the wort under the surface so there's no splashing/aeration.

Cheers

[emoji897]I still dont get the LODO thing. I mean I understand what youre trying to do but it still seems like a lot of counterproductive steps .

I gravity transfer because when I did try a pump I quickly lost temperature and I felt the pump impeller added aeration where i didnt want it. Not to mention one more place or process that could harbor bacteria /mold and therefore , infection.

From what Ive read and understood up til now, the cold side ,as long as you dont promote any unnecessary aeration in your process, the hot side process will eliminate yet before the fermentation process ,one is instructed to aerate the wort prior to pitching. I believe this is where most people misunderstand and they think they must oxygenate with pure oxygen rather than a simple splashing about of the chilled wort.

I know of no brewery that purposely adds pure oxygen .

I do make sure I keep my grains sealed and I crush my grain as soon as I can before adding to the mash tun. I gently transfer making sure to not splash any part of the process until it heads into the fermenter,then it gets a slow crack of the ball valve which draws in air to the wort (air bubbles in the clear tubing shows this) which both helps further the chill and aerates it when it enters in a splashing frothing 2 ft drop.

Don't get me wrong .

If it works for you then by all means continue.

FTR - This is not the right place to debate LOB Methodology. Specifically in point to it's value in home brewing unless you want to explain a better method of LOB brewing.I still dont get the LODO thing. I mean I understand what youre trying to do but it still seems like a lot of counterproductive steps .

I gravity transfer because when I did try a pump I quickly lost temperature and I felt the pump impeller added aeration where i didnt want it. Not to mention one more place or process that could harbor bacteria /mold and therefore , infection.

From what Ive read and understood up til now, the cold side ,as long as you dont promote any unnecessary aeration in your process, the hot side process will eliminate yet before the fermentation process ,one is instructed to aerate the wort prior to pitching. I believe this is where most people misunderstand and they think they must oxygenate with pure oxygen rather than a simple splashing about of the chilled wort.

I know of no brewery that purposely adds pure oxygen .

I do make sure I keep my grains sealed and I crush my grain as soon as I can before adding to the mash tun. I gently transfer making sure to not splash any part of the process until it heads into the fermenter,then it gets a slow crack of the ball valve which draws in air to the wort (air bubbles in the clear tubing shows this) which both helps further the chill and aerates it when it enters in a splashing frothing 2 ft drop.

Don't get me wrong .

If it works for you then by all means continue.

[emoji897]

Umm, this is the "LoDo Discussion and Techniques" sub-forum. This is exactly where such discussion should take place (as long as it's respectful.)FTR - This is not the right place to debate LOB Methodology. Specifically in point to it's value in home brewing unless you want to explain a better method of LOB brewing.

FTR, i believe i just did. I mean whats the sense is doing everything possible to eliminate any oxidation when in the last step before pitching, you do everything possible to do just the opposite?FTR - This is not the right place to debate LOB Methodology. Specifically in point to it's value in home brewing unless you want to explain a better method of LOB brewing.

Very simply, you only oxygenate wort after active yeast has been pitched. The yeast rapidly scavenge all available oxygen for their needs. At any other point in the process, from milling to mashing, lautering, boiling, chilling, and after fermentation has begun, exposure to oxygen is very harmful, and reactions proceed very quickly in many cases with permanent results. So oxygenation at pitching is a special circumstance, the only time you want oxygen; and it does not have a chance to oxidize wort before yeast consumes it. (On the professional level, there has been much research to see if even oxygenation of yeast at pitching could be eliminated by providing yeast with some other aid to sterol synthesis.) HTH. PS I was a skeptic too. But the beer speaks for itself when you start to apply low oxygen methods.FTR, i believe i just did. I mean whats the sense is doing everything possible to eliminate any oxidation when in the last step before pitching, you do everything possible to do just the opposite?

This is why i dont understand it. Maybe instead of me explaining why I should have a better idea , you explain to me so i may understand your method.

Im not here to argue , im trying to understand.

Well, that's a little different.FTR, i believe i just did. I mean whats the sense is doing everything possible to eliminate any oxidation when in the last step before pitching, you do everything possible to do just the opposite?

This is why i dont understand it. Maybe instead of me explaining why I should have a better idea , you explain to me so i may understand your method.

Im not here to argue , im trying to understand.

I think the professional brewers oxygenate during the transfer to the fermentor with an inline diffuser. I've never saw one that's what I've heard was done.I still dont get the LODO thing. I mean I understand what youre trying to do but it still seems like a lot of counterproductive steps .

I gravity transfer because when I did try a pump I quickly lost temperature and I felt the pump impeller added aeration where i didnt want it. Not to mention one more place or process that could harbor bacteria /mold and therefore , infection.

From what Ive read and understood up til now, the cold side ,as long as you dont promote any unnecessary aeration in your process, the hot side process will eliminate yet before the fermentation process ,one is instructed to aerate the wort prior to pitching. I believe this is where most people misunderstand and they think they must oxygenate with pure oxygen rather than a simple splashing about of the chilled wort.

I know of no brewery that purposely adds pure oxygen .

I do make sure I keep my grains sealed and I crush my grain as soon as I can before adding to the mash tun. I gently transfer making sure to not splash any part of the process until it heads into the fermenter,then it gets a slow crack of the ball valve which draws in air to the wort (air bubbles in the clear tubing shows this) which both helps further the chill and aerates it when it enters in a splashing frothing 2 ft drop.

Don't get me wrong .

If it works for you then by all means continue.

FTR, i believe i just did. I mean whats the sense is doing everything possible to eliminate any oxidation when in the last step before pitching, you do everything possible to do just the opposite?

This is why i dont understand it. Maybe instead of me explaining why I should have a better idea , you explain to me so i may understand your method.

Im not here to argue , im trying to understand.

I could do that, but this way involves less moving hoses (right?). It's still "underletting" since it fills from the bottom.Looking at your flow chart .... in step 1 if you go kettle -> pump -> mash tun drain you can underlet your grain. I'm not LODO but did adopt this LODO underletting practice and really like how it works. Even mostly pilsner grists which used to give me incredibly tough dough balls wet very nicely with underletting.

I know of no brewery that purposely adds pure oxygen .

LOL I had to go back and re-read. Post #32 explains. OK sounds good. Nice use of that feature.I could do that, but this way involves less moving hoses (right?). It's still "underletting" since it fills from the bottom.

As a matter of fact, I do. This was my plan as I was picking out all my new fittings (I'm upgrading to all 1/2" tubing with ball-lock quick connects).

My brew day has 7 flow paths. It'll be single tier with no gravity transfers.

In order:

- Transfer water from kettle (being used as HLT) to the mash tun.

- Recirculate the mash through the RIMS.

- Transfer the wort to the kettle.

- Recirculate wort through the CFC to chill.

- Ground water chilling phase.

- Ice water recirculation chilling phase.

- Transfer chilled wort from kettle to fermenter.

Hoses are labeled with letters.

View attachment 639366

As to the "why" ... This is the Low Oxygen Brewing subforum. By eliminating oxygen on both the hot side and cold side we can make beer with amazing flavor.

My RIMS needs to return the wort under the surface so there's no splashing/aeration.

Cheers

Yes I move hose A. The hose stays full since I only disconnect the top side, so only a small bubble gets in. Otherwise the system stays full until chilling.Are you moving hose A when you go from the top configuration to the second one down(mashing phase)?

If so how do you do that without getting air in the hose, do you have some hardware to help purge it?

Say the bubble is 5mL...Assuming with the straight bulk head pipe and bazooka screen the small bubble goes back into the mash tun and not thru the pump.

It's just called a spiral nozzle. It's designed to create a spray, so I guess you could say it's repurposed.The spiral thing is interesting. Did you repurpose something or was it specially build for that purpose?

Say the bubble is 5mL...

Ideal gas law

n = P * V / ( R * T )

n = 1atm * 0.005L / ( 0.082057L*atm/K/mol * 373.15 K )

n = 0.00016329 mol of atoms in the air bubble

Multiply by 0.21 to get the mole of oxygen...

0.000034287 mol oxygen

0.54860 mg oxygen

Let's say the mash is about 8 gallons (~30L). 0.54860mg gives 0.0183 ppm of oxygen, which will neutralize less than 0.1ppm of sulfite, entirely negligible.

Feel free to check my math.

It's just called a spiral nozzle. It's designed to create a spray, so I guess you could say it's repurposed.

https://www.amazon.com/Padory-Stainless-Atomization-Sprinkler-External/dp/B07BT7D2J9

The height is easily adjustable on the fly. After using it to underlet, I set it to return a few inches below the surface.Am I right that your spiral recirculation return would be quite deep down in your mash bed?

I can hear if there's a bubble in the pump. The pump output is at the top so I just turn the pump off for a few seconds to allow the bubble to escape. Easy peasy!My thought was how to keep the bubble from getting into the RIMS and potentially creating an air pocket around the temp probe. Or to keep it from causing the pump to stall. But the math stuff is good too know.