OK HBT,

Warning... this will be a controversial post! Opinions are mine - take with a grain of salt!

One of the home brewery configurations still used in new builds is HERMs to perform mash temperature control. Conceptually, it doesn't make much sense to me: in order to heat liquid, you need to first heat other liquid. Why not just heat the liquid you want and be done? I believe in the "old days", an HLT was needed to heat water, and that HLT required a power circuit (element, SSR, contactor, PID, wiring, plugs, etc.). 30A breweries cannot run multiple elements simultaneously, and since that HLT was already there, the builder could just re-use that power circuit, hence running the mash liquid back through the HLT volume via HERMs coils.

This is of course why RIMs was created - but RIMs gets a bad reputation. If the brewer wants to run one, they need an additional power circuit to the HLT one, which adds cost, complexity, etc. That's where high power RIMs can come in... a full-power RIMs element can replace the HLT altogether and serve the function of heating strike water, maintaining mash temp, mashing out, and direct heat sparging. My personal rig uses a 5500 W element in the RIMs tube and employs a high/low relay to adjust its power between 1350 and 5500 W. It uses full power for strike water heating, mashing out, and direct heat fly-sparging and low power for mash temp steps and maintenance. Low power is used to protect the mash from the evil but mostly mythical "scorching" devil. I think that a simpler implementation of this can be used: either via software or hardware, or both.

Using software: all PIDs I am aware of have an option to limit the PID maximum output of an element. Theoretically, capping the max output of the PID to 25% during mashing will serve the same net function as a high/low relay. This can be done manually, or in BruControl, can be changed on the fly with a script command (e.g. "RIMs" MaxOutput = 25).

But what about hardware? There is no doubt that a 5500 W straight LWD (Low Wattage Density) element at 120 watts per square inch does not offer the same scorching protection as a ULWD (Ultra Low Wattage Density) element. I have personally not had any scorching in 25+ brews using this element, having applied full power to wort during mash out. But understandably many would be apprehensive.

All this said, I think a two-vessel RIMs direct heat fly-sparge system (aka 2VDS) is the best possible configuration. The hardware, space, and cost of the HLT and HERMs hardware is eliminated, accessory hardware like valves and tubing is reduced, 3 vessel benefits such as efficiency and clear wort are maintained, mash steps occur quickly and accurately independent of batch size, the brew day is faster and simplified, and control panels are no more complex than HERMs. The only complexity to implementing direct heat fly-sparging is the need to fix the incoming water rate. Here is a simple flow diagram:

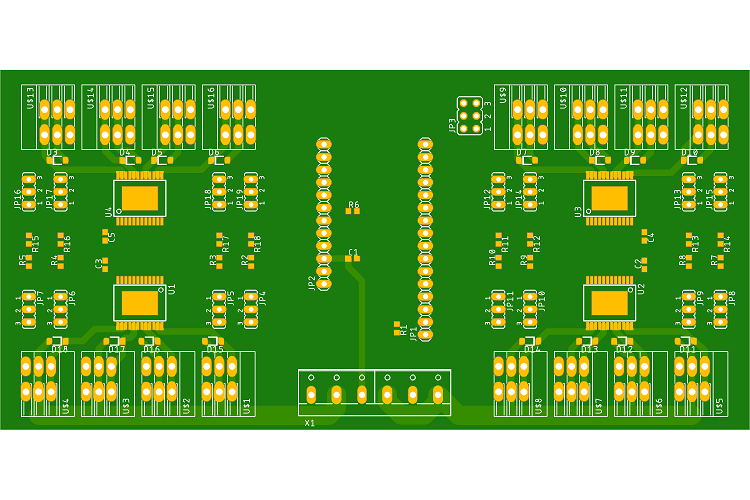

View attachment 566055

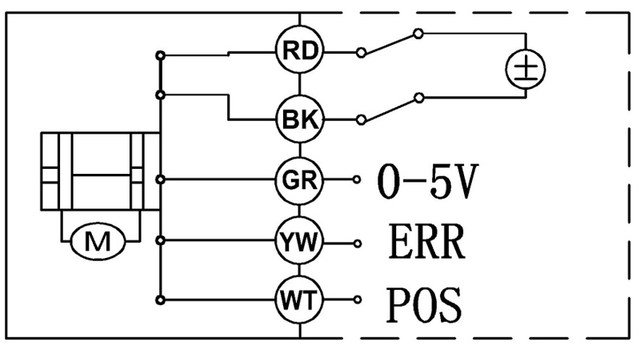

I am so convinced the world needs to move past HERMs, I am putting my money where my mouth is! I have had a custom RIMs tube element made, purpose suited for this application, which we are fondly calling "QuadZilla". This is a ULWD element assembly, especially made for high-power RIMs applications in brewing. The QuadZilla is an assembled four-pack of 304 stainless steel sheathed cartridge heaters welded in a 1.5" tri-clamp cap. Each heater provides 1375 W @ 240 VAC for a total power of 5500 W and the heat density is 61 watts per square inch (9.5 W/cm^2), which is equivalent to the 5500 W ripple elements used in home brew boil kettles. Now, brewers can build a RIMs tube and run it at full power without concern of scorching. Used vertically, there is no need for RIMs flow switches or flowmeters to halt power in case of a stuck mash. In addition, they can heat strike water, mashout, and direct heat fly-sparge very easily. See more here:

http://brucontrol.com/buy/quadzilla/

View attachment 566056

I have no intentions of offending lovers of HERMs here - one of the great aspects of our hobby is the different ways we approach making beer. But I strongly feel it is time to advance past the ways of old, in the same way I believe automation greatly improves our beer. I look forward to a healthy discussion and hope many others will see the benefits of a 2VDS configuration and this RIMs element. Special thanks to

@augiedoggy for the general concept of cartridge heaters in RIMs applications.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)