doublehaul

Well-Known Member

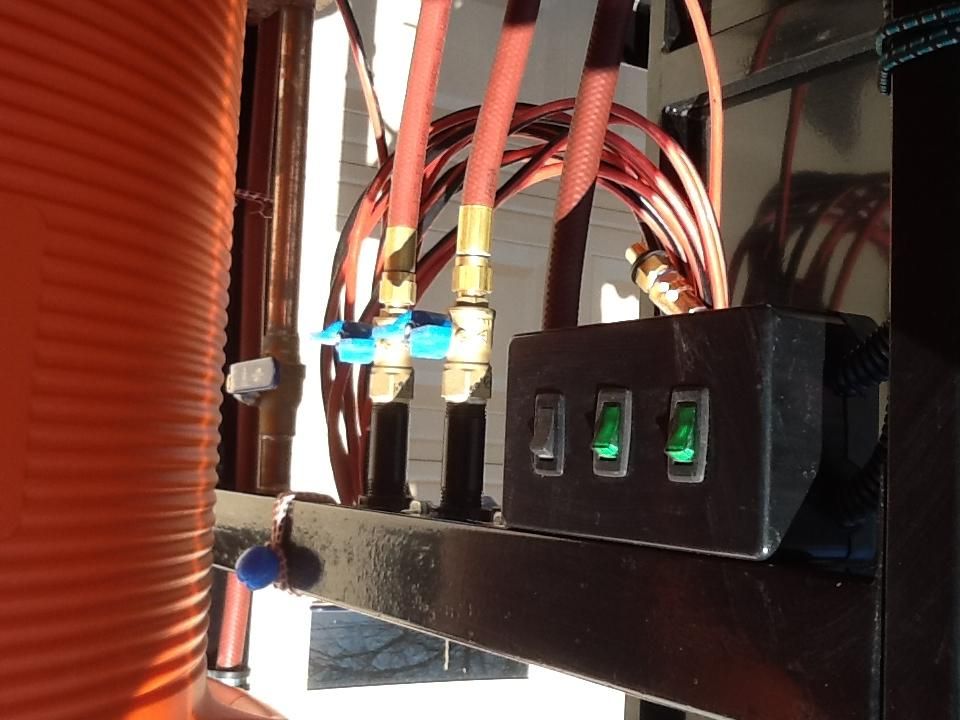

The brewstand has been commissioned!

I wanted a lower design, most stands seem too tall to me. I figure with casters, it will be about 24" high. The metal stand itself will be 21". Does anyone see issue with only 21" of stand height as far as a pump gravity priming OK?

I wanted a lower design, most stands seem too tall to me. I figure with casters, it will be about 24" high. The metal stand itself will be 21". Does anyone see issue with only 21" of stand height as far as a pump gravity priming OK?