I'd probably pour the yeast and starter in a big sanitized pitcher, and decant, and then guestimate the amount of slurry and guestimate the proper pitch amount. "Close enough" is close enough for me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oatmeal Stout Yooper's Oatmeal Stout

- Thread starter Yooper

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I'd probably pour the yeast and starter in a big sanitized pitcher, and decant, and then guestimate the amount of slurry and guestimate the proper pitch amount. "Close enough" is close enough for me.

I think that's what I'll probably do.

Thanks!

GrogNerd

mean old man

double post

GrogNerd

mean old man

Ok, this is a double post to a new thread I just posted, but I'm fishing for feedback.

So, I'm doing my first 10 gal batch this weekend, and it's basically this recipe. I began my yeast starter yesterday. Turns out, I had the calculator set to lager pitch rate. I had thought I needed to do one step yesterday, and then was planning on stepping up again tomorrow. I should have checked my numbers, but it's too late now. I have roughly 3L of starter right now which is already an over pitch for my recipe.

My calculated pitch should be 392 Billion Cells. The starter I have going calculates out to 479 Billion Cells.

I would normally say, I'll just pour some off. Problem is, the yeast is wy1968, and it floccs like a beast. It's not exactly a homogenous mixture that can easily be portioned out.

Should I... Just over pitch.

Should I... Try to pour off some and take close enough.

Should I... Bump up the recipe with some DME to make the yeast I have a more proper pitch. My recipe is 1.052, but 1.064 would make the starter I have on target. Not sure I'd go that far with DME, but maybe 1.058-1.060.

Should I... Any other ideas?

Cheers.

go with option 2... save some for another day, another batch

edit (posted before I saw Yooper's post): don't listen to me

mesooohoppy

Well-Known Member

I brewed this about 2 months ago and had one last night.

Mine came out super thin. I hit all of the numbers and everything. Does this have anything to do with the 'thin mash'?

Mine came out super thin. I hit all of the numbers and everything. Does this have anything to do with the 'thin mash'?

I brewed this about 2 months ago and had one last night.

Mine came out super thin. I hit all of the numbers and everything. Does this have anything to do with the 'thin mash'?

No. The thin mash, in my case, was to hit my mash pH numbers.

"Thin" is not something I've seen with this beer as the flaked barley seems to really give it body and a rocky head. Its it carbed up appropriately?

mesooohoppy

Well-Known Member

I bottled 10/16 (3 days short of a month in the bottle).

There was very little to no carbonation, not sure why as my stuff is usually carb'd up by now. Although, the beer was super thin.. I even had a friend drink it who usually drinks crap and he said it was super thin too.

I am going to brew a batch of this again later today. Just trying to figure out where I am screwing up.. I can't seem to make one decent batch of beer without it having some major flaw.

There was very little to no carbonation, not sure why as my stuff is usually carb'd up by now. Although, the beer was super thin.. I even had a friend drink it who usually drinks crap and he said it was super thin too.

I am going to brew a batch of this again later today. Just trying to figure out where I am screwing up.. I can't seem to make one decent batch of beer without it having some major flaw.

Biscuits

Well-Known Member

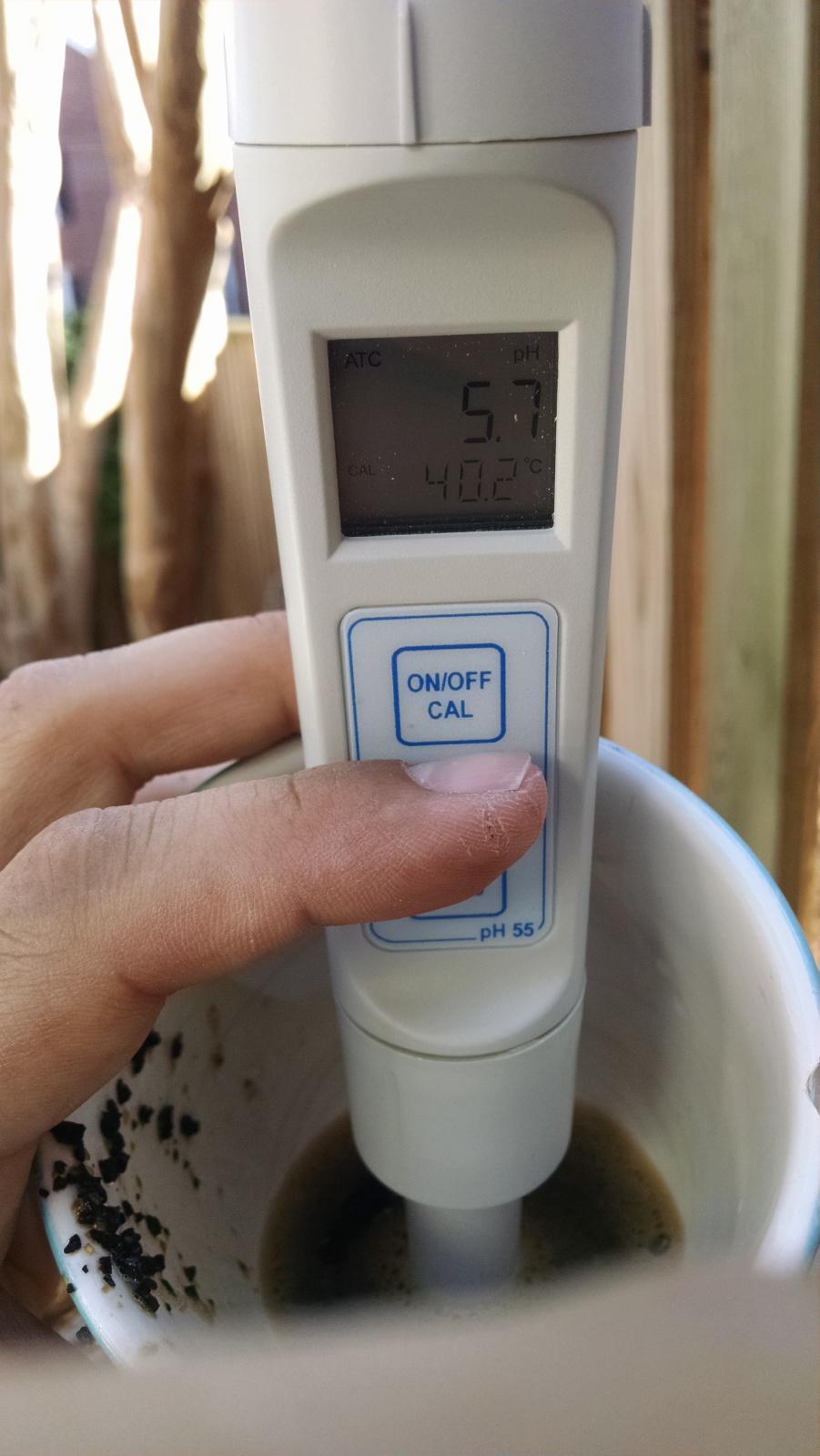

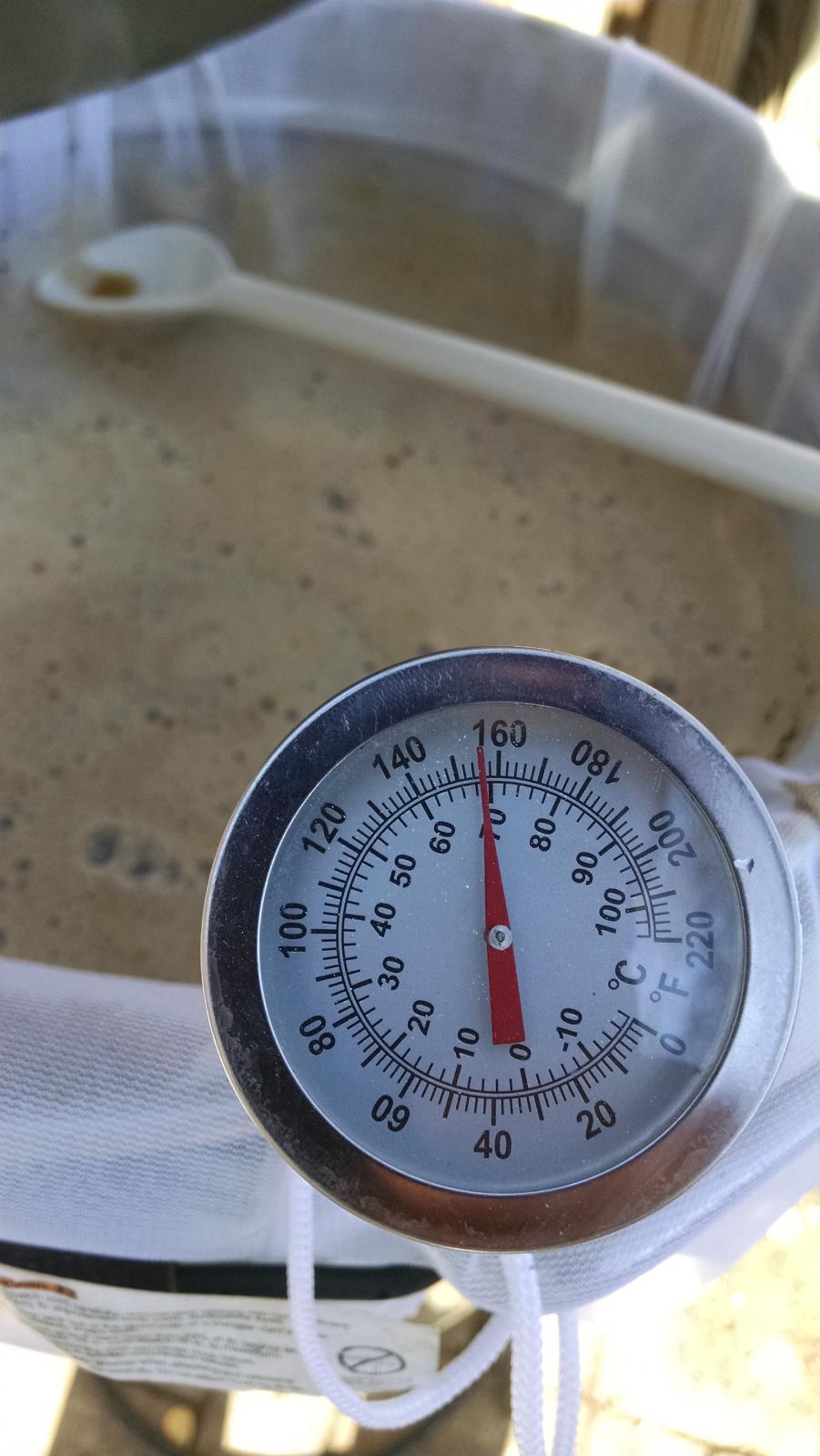

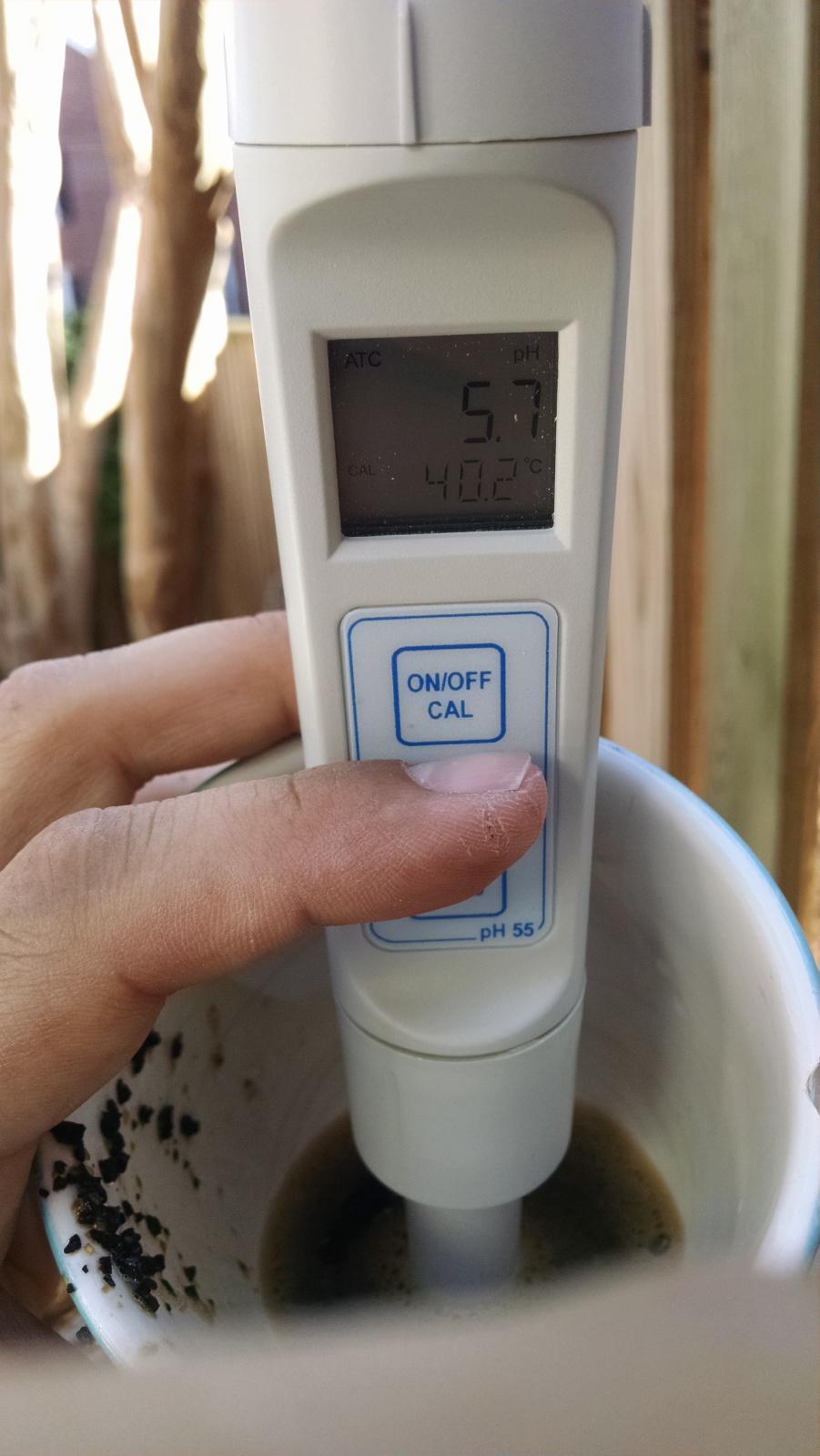

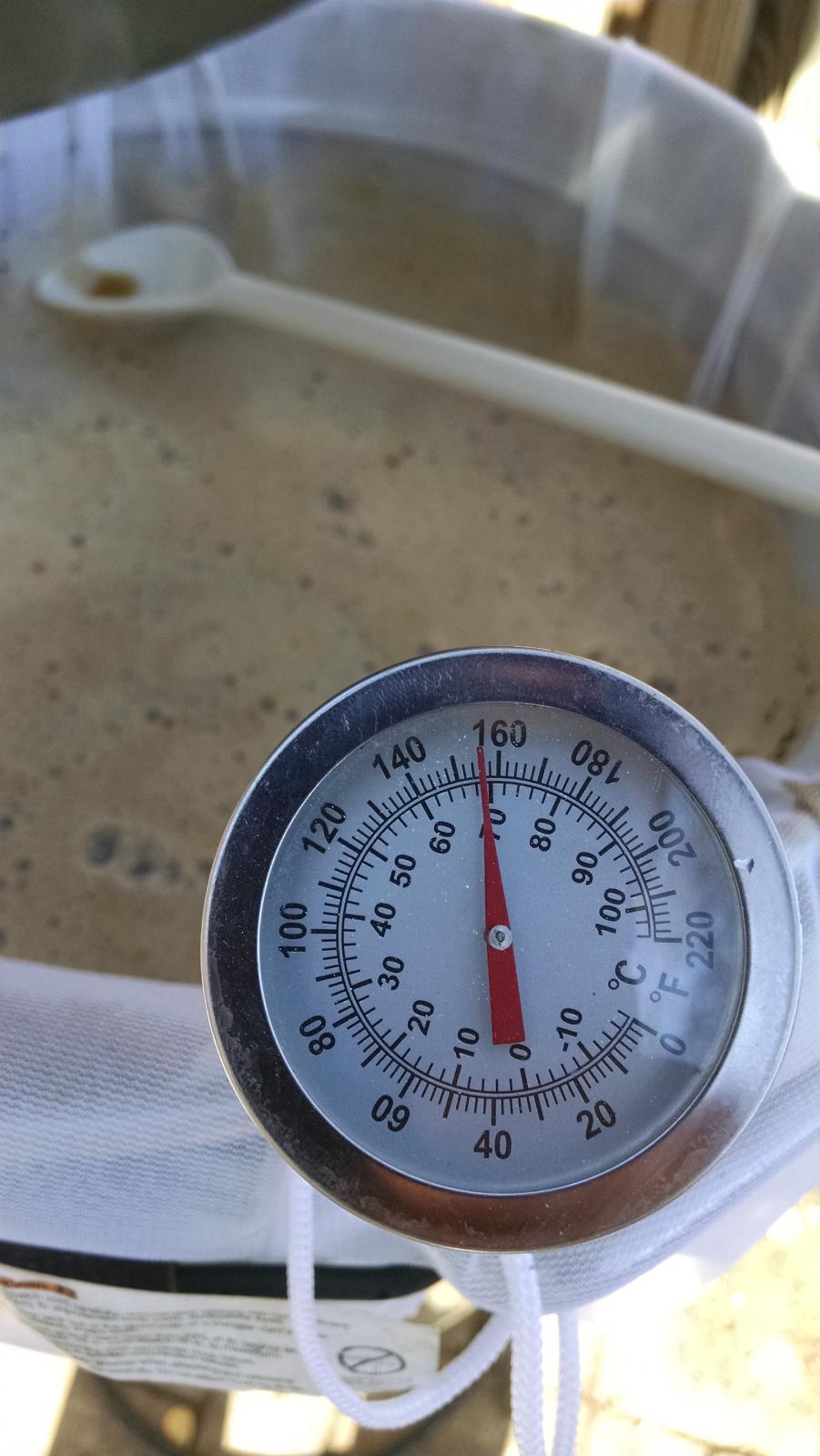

I am mashing this in right now...so far my pH and mash temp look spot on!

chalkdust41485

This is no hobby....

I am mashing this in right now...so far my pH and mash temp look spot on!

Just on a side note, have you verified temps with that kind of thermometer? I found mine to be off by about 5-7 degrees. Those mechanical types of thermometers have been known to be really inaccurate. (mostly meant to show a ballpark temperature for frying turkeys) I bought a cheap but good digital thermometer and have been really happy with it knowing that my readings are accurate.

jrowland74

Well-Known Member

Just on a side note, have you verified temps with that kind of thermometer? I found mine to be off by about 5-7 degrees. Those mechanical types of thermometers have been known to be really inaccurate. (mostly meant to show a ballpark temperature for frying turkeys) I bought a cheap but good digital thermometer and have been really happy with it knowing that my readings are accurate.

I can attest to this. I have 2 of these thermometers. One is spot on, and the other is 4 degrees off. They are great in the sense that they are really hard to break and easy to clean, but make sure you check it's accuracy on occasion.

Biscuits

Well-Known Member

Just on a side note, have you verified temps with that kind of thermometer? I found mine to be off by about 5-7 degrees. Those mechanical types of thermometers have been known to be really inaccurate. (mostly meant to show a ballpark temperature for frying turkeys) I bought a cheap but good digital thermometer and have been really happy with it knowing that my readings are accurate.

Actually yes. I calibrated it not too long ago and it was right where it should be. Although, I am still going to invest in a thermopen sometime in the near future.

I'm on my second attempt at this recipe and I had a similar problem the first time. OG was 1.059, but only got to 1.033 after a week (and stayed there for two more). I tried rousing the yeast with a temperature raise and pitching new (S-04) yeast and neither worked so I dumped it since I didn't want to risk bottle bombs. I think my problem was I using frozen water bottles in an attempt to cool the fermenter and may have overdone it. It worked fine on the Cream Ale I did before that but was a lot warmer in the house at that time.

On my current attempt I mashed at 152 instead of 156 and left the fermenter alone. Started at 1.067 (likely due to a much more vigorous squeezing of my BIAB bag) and it's sitting stable at 1.027 after 10 days. It's looking a lot better than my first attempt (58% attenuation vs 42%) and if you look at the original recipe it was only 68%. I'll likely bottle this batch (targeting a low CO2 volume) and risk it...

Next time I'll likely switch to either Denny's Favorite yeast or Wyeast 1318 and see how that affects things.

Yeah, once I noticed that the attenuation in the recipe was already low, in addition to finding out that this yeast is a notorious under-attenuator anyhow, I decided not to worry about it. I went ahead and bottled it, it tasted delicious! Now I just have to wait for it to carb up.

brennanj11

Well-Known Member

Yooper!! Thank you for this wonderful recipe. Followed the grain and hops and used WLP002.

FG finished very low @ 1.012! So I finished at 6.5%!

After 3 weeks in the primary and 10 days in the bottle the flavor is smooth, milky, chocolaty with a subtle roast character.

No acrid or heavy roast notes.

I'm going to use this as a base for some experimentation with coffee, different priming sugars, and vanilla.

FG finished very low @ 1.012! So I finished at 6.5%!

After 3 weeks in the primary and 10 days in the bottle the flavor is smooth, milky, chocolaty with a subtle roast character.

No acrid or heavy roast notes.

I'm going to use this as a base for some experimentation with coffee, different priming sugars, and vanilla.

You know that the ball valve is supposed to be open during fermentation right? Otherwise the yeast will cake over the valve and block it up

I'm waiting for the trub to settle a bit and then I'll open the valve, thanks.

Interesting. What could you not source to recipe at your LHBS?

I went with 12 oz chocolate 350 because they didn't have the light and dark chocolate malts. A small compromise in my estimation.

I can strongly recommend addition of vanilla beans.

What have you found best for adding vanilla? I'd definitely like to try this. I have some beans in vodka now. I'm curious about the dosage.

BrewMeister49

Well-Known Member

Hey - I found your Oatmeal Stout recipe and it calls for Wyeast british 2 yeast. My LHBS only carries Whitelabs. I was wondering what you would recommend, British ale, Irish ale, or....? Seems like an awesome recipe! Anything you would change? I dont know if our brew shop carries pale chocolate malt either, so I am just using that amount as roasted barley. Here is what I have so far on Beersmith. The yeast is just down on there to get something. Wanted your input since you are the mastermind behind this recipe

7 lbs Pale Malt, Maris Otter (3.0 SRM) Grain 1 66.4 %

1 lbs Oats, Flaked (1.0 SRM) Grain 2 9.5 %

12.8 oz Victory Malt (25.0 SRM) Grain 3 7.6 %

8.0 oz Black Barley (Stout) (500.0 SRM) Grain 4 4.7 %

8.0 oz Caramel/Crystal Malt - 80L (80.0 SRM) Grain 5 4.7 %

8.0 oz Roasted Barley (300.0 SRM) Grain 6 4.7 %

4.0 oz Chocolate Malt (450.0 SRM) Grain 7 2.4 %

2.00 oz Willamette [5.50 %] - Boil 60.0 min Hop 8 37.1 IBUs

1.0 pkg British Ale (White Labs #WLP005) [35.49 ml] Yeast 9 -

Gravity, Alcohol Content and Color

Est Original Gravity: 1.057 SG

Est Final Gravity: 1.014 SG

Estimated Alcohol by Vol: 5.6 %

Bitterness: 37.1 IBUs

Est Color: 35.5 SRM

7 lbs Pale Malt, Maris Otter (3.0 SRM) Grain 1 66.4 %

1 lbs Oats, Flaked (1.0 SRM) Grain 2 9.5 %

12.8 oz Victory Malt (25.0 SRM) Grain 3 7.6 %

8.0 oz Black Barley (Stout) (500.0 SRM) Grain 4 4.7 %

8.0 oz Caramel/Crystal Malt - 80L (80.0 SRM) Grain 5 4.7 %

8.0 oz Roasted Barley (300.0 SRM) Grain 6 4.7 %

4.0 oz Chocolate Malt (450.0 SRM) Grain 7 2.4 %

2.00 oz Willamette [5.50 %] - Boil 60.0 min Hop 8 37.1 IBUs

1.0 pkg British Ale (White Labs #WLP005) [35.49 ml] Yeast 9 -

Gravity, Alcohol Content and Color

Est Original Gravity: 1.057 SG

Est Final Gravity: 1.014 SG

Estimated Alcohol by Vol: 5.6 %

Bitterness: 37.1 IBUs

Est Color: 35.5 SRM

Singletrack

Because it's judgement that defeats us.

WLP 025 Southwold Ale, per Kristen England's cross reference chart. I haven't used this yeast, nor Wyeast British Ale II. Lastly, I'm not Yooper, but maybe this helps anyway.

WLP025 Southwold Ale Yeast

From Suffolk county, England. This yeast produces complex fruit, citrus, and spicy flavors. Great for British bitters and pale ales. Slight sulfur is produced during fermentation, which will disappear with aging.

Attenuation68-75%

FlocculationMedium

Optimum Ferment Temp.66-69°F (18-20°C)

Alcohol ToleranceMedium

WLP025 Southwold Ale Yeast

From Suffolk county, England. This yeast produces complex fruit, citrus, and spicy flavors. Great for British bitters and pale ales. Slight sulfur is produced during fermentation, which will disappear with aging.

Attenuation68-75%

FlocculationMedium

Optimum Ferment Temp.66-69°F (18-20°C)

Alcohol ToleranceMedium

BrewMeister49

Well-Known Member

I dont think that would fit too well for an Oatmeal Stout  Citrusy/Fruity doest really blend with chocolatey/roasty.

Citrusy/Fruity doest really blend with chocolatey/roasty.

Singletrack

Because it's judgement that defeats us.

I dont think that would fit too well for an Oatmeal StoutCitrusy/Fruity doest really blend with chocolatey/roasty.

Ha! Well, sure, if you want to get all practical about it, and if you trust the White Labs description, then WLP 025 seems like an awful choice. Regardless, if Kristen says its the same yeast, I think you have no choice but to blindly use it and report results. Could be the best citrusy/fruity/chocolately/roasty beer you ever had.

JLeuck64

Well-Known Member

Mashing in this recipe right now! (10/3/15)

Edit: and several hours later... I have 6 gallons of wort @ 1.053 O.G. !!!

Edit: and 3 weeks later (10/25/15) it finished at 1.016, capped 61 bottles in total. It's a complex tasting stout! Looking forward to tasting it in another 6 weeks ( ;

Edit: and 2 days after bottling I couldn't stand it so I uncapped one... it fizzed! Used Denny's Fav 50, it was green obviously but seriously tastes like one of THOSE stouts that will get so good in a month or so. (think I will uncap a second one LOL)

Update: After bottling conditioning for a month now (11/24/15), this batch is REALLY starting to develop it's flavor!!!

Really wish there was an Imperial Version of this recipe... ( ;

What was the fg of yours? I'm sitting at 1.023 using wlp007. Sound about right? Also og was 1.061.

I checked my notes, and the two times I brewed this, my FG was 1.021 and 1.023, respectively. I mashed high--around 156F, so that's about what I expected. It turned out great both times.

jrowland74

Well-Known Member

Mine ended up at 1.018. It was a little harsh at first, but after just a couple weeks in the keg, it's now pretty fantastic!

theotherbuzzy

Member

- Joined

- Oct 31, 2015

- Messages

- 5

- Reaction score

- 0

On my current attempt I mashed at 152 instead of 156 and left the fermenter alone. Started at 1.067 (likely due to a much more vigorous squeezing of my BIAB bag) and it's sitting stable at 1.027 after 10 days. It's looking a lot better than my first attempt (58% attenuation vs 42%) and if you look at the original recipe it was only 68%. I'll likely bottle this batch (targeting a low CO2 volume) and risk it...

Sadness... The bottles turned into gushers after only a week; there must have been something fermentable left (doesn't taste like an infection). The beer was otherwise pretty good (I rounded up too much when scaling the recipe and the alcohol content is just too high)...I just have to open two bottles to get one good pour

Next time I'll try a better attenuating yeast and scale down the OG a little.

Next up Yooper's DFH60 clone

BrewMeister49

Well-Known Member

What would create the gushers? How much corn sugar did you use at bottle? I hover around 114grams 3/4 cup for my 5 gallon batches. Like you said with incomplete fermentation would be the only other thing that comes to mind. But if it were steady at 1.023 and no activity in the airlock?

theotherbuzzy

Member

- Joined

- Oct 31, 2015

- Messages

- 5

- Reaction score

- 0

What would create the gushers? How much corn sugar did you use at bottle? I hover around 114grams 3/4 cup for my 5 gallon batches. Like you said with incomplete fermentation would be the only other thing that comes to mind. But if it were steady at 1.023 and no activity in the airlock?

I'm fairly new to brewing and did a LOT of reading after the fact, but from what I can tell infection and too much fermentables are the main causes of gushers. A prior batch (porter with Belgian yeast) started out tasting fine but gradually (over 8-12 weeks) got more odd tasting and eventually started gushing from the bottles. I initially thought the odd taste was caused by fusel alcohols (I had to ferment at a high temp, hence the choice of a Belgian saison yeast)....but I guess it was an infection. I did have a rather bad head cold when I brewed so I may have made some mistakes.

On this batch I'm thinking/hoping it was just an incomplete fermentation, especially since it carbed up in 3 days and was gushing by 7. I used a BeerSmith to calculate the corn sugar addition (and carbed low at 2.0 volumes). I tried rousing the yeast and warming it up as well as pitching some US-05 and nothing helped the FG. I can only guess that when I racked the beer into my bottling bucket, it woke things up again (maybe the additional oxygen of being in the open bucket caused it).

it carbed up in 3 days and was gushing by.

It takes longer than 3 days to carb a beer. At 7 the co2 hasn't had enough time to 'become one' with the beer. That's probably why it gushed. Try 3 weeks in bottle and a few days in the fridge before you crack open another.

Biscuits

Well-Known Member

I'm fairly new to brewing and did a LOT of reading after the fact, but from what I can tell infection and too much fermentables are the main causes of gushers. A prior batch (porter with Belgian yeast) started out tasting fine but gradually (over 8-12 weeks) got more odd tasting and eventually started gushing from the bottles. I initially thought the odd taste was caused by fusel alcohols (I had to ferment at a high temp, hence the choice of a Belgian saison yeast)....but I guess it was an infection. I did have a rather bad head cold when I brewed so I may have made some mistakes.

From what I understand, if it were an infection, you would most likely have had gushers and/or bottle bombs because the wild yeast would eat any/all sugars which would create a lot more CO2. I am thinking the bad taste developed over time from something else, maybe oxidation.

On this batch I'm thinking/hoping it was just an incomplete fermentation, especially since it carbed up in 3 days and was gushing by 7. I used a BeerSmith to calculate the corn sugar addition (and carbed low at 2.0 volumes). I tried rousing the yeast and warming it up as well as pitching some US-05 and nothing helped the FG. I can only guess that when I racked the beer into my bottling bucket, it woke things up again (maybe the additional oxygen of being in the open bucket caused it).

Did you notice any film or sediment forming in the neck of the bottles? The only time I had gushers/bottle bombs was from when I accidentally dropped a dust display bottle into my bottling bucket when I was bottling. I noticed stuff accumulating at the top of the beer level in the neck of the bottle.

I can't say whether or not CO2 not being dissolved into solution would cause gushers or not, but I know that I frequently crack beers well before the conditioning is completed so that I can try and perceive differences after some aging..and I have never had a gusher from it.

burninator

Well-Known Member

- Joined

- Jul 27, 2014

- Messages

- 992

- Reaction score

- 351

Brewed my first batch of this today, and boy does it look and smell good. I used Nottingham, as it was the English yeast I had on hand. Looking forward to this one. Thanks, Yoop!

Bottled 5 gallons today.

OG: 1.058

FG: 1.020

Mash started at 158

Used Nottingham since I don't have the equipment for liquid yeast and don't like S04.

The hydrometer sample tasted spectacular.

I can't wait, can't wait, can't wait to drink this once it's bottle conditioned.

Did I mention I can't wait to drink this beer?

Fantastic recipe

Thanks Yooper

OG: 1.058

FG: 1.020

Mash started at 158

Used Nottingham since I don't have the equipment for liquid yeast and don't like S04.

The hydrometer sample tasted spectacular.

I can't wait, can't wait, can't wait to drink this once it's bottle conditioned.

Did I mention I can't wait to drink this beer?

Fantastic recipe

Thanks Yooper

theotherbuzzy

Member

- Joined

- Oct 31, 2015

- Messages

- 5

- Reaction score

- 0

Did you notice any film or sediment forming in the neck of the bottles? The only time I had gushers/bottle bombs was from when I accidentally dropped a dust display bottle into my bottling bucket when I was bottling. I noticed stuff accumulating at the top of the beer level in the neck of the bottle.

The only thing I noticed was the typical sediment at the bottom due to being bottle conditioned (and maybe some hop debris...the beer is so dark I couldn't really tell when I started hitting the trub with the siphon).

In any case I spent last night gently prying up the caps just enough to vent the bottles (and still remain sealed when I stopped prying). I got them to the point where the beer didn't foam up at room temperature, so hopefully it'll fix the carbonation.

The only thing I noticed was the typical sediment at the bottom due to being bottle conditioned (and maybe some hop debris...the beer is so dark I couldn't really tell when I started hitting the trub with the siphon).

In any case I spent last night gently prying up the caps just enough to vent the bottles (and still remain sealed when I stopped prying). I got them to the point where the beer didn't foam up at room temperature, so hopefully it'll fix the carbonation.

Carbonation has a hard time staying in the solution at room temp and when the beer is young. I've had 'gushers' early on some stouts (the only type of beer I dont mind at room temp) when cracking open some prematurely. Weeks later and no gushers even at room temp. Sounds like you need to be a little more patient and actually wait the recommended 3 weeks.

Similar threads

- Replies

- 22

- Views

- 527

- Replies

- 11

- Views

- 1K

- Replies

- 11

- Views

- 687

- Replies

- 30

- Views

- 1K