fendersrule

Well-Known Member

- Joined

- Oct 11, 2018

- Messages

- 703

- Reaction score

- 341

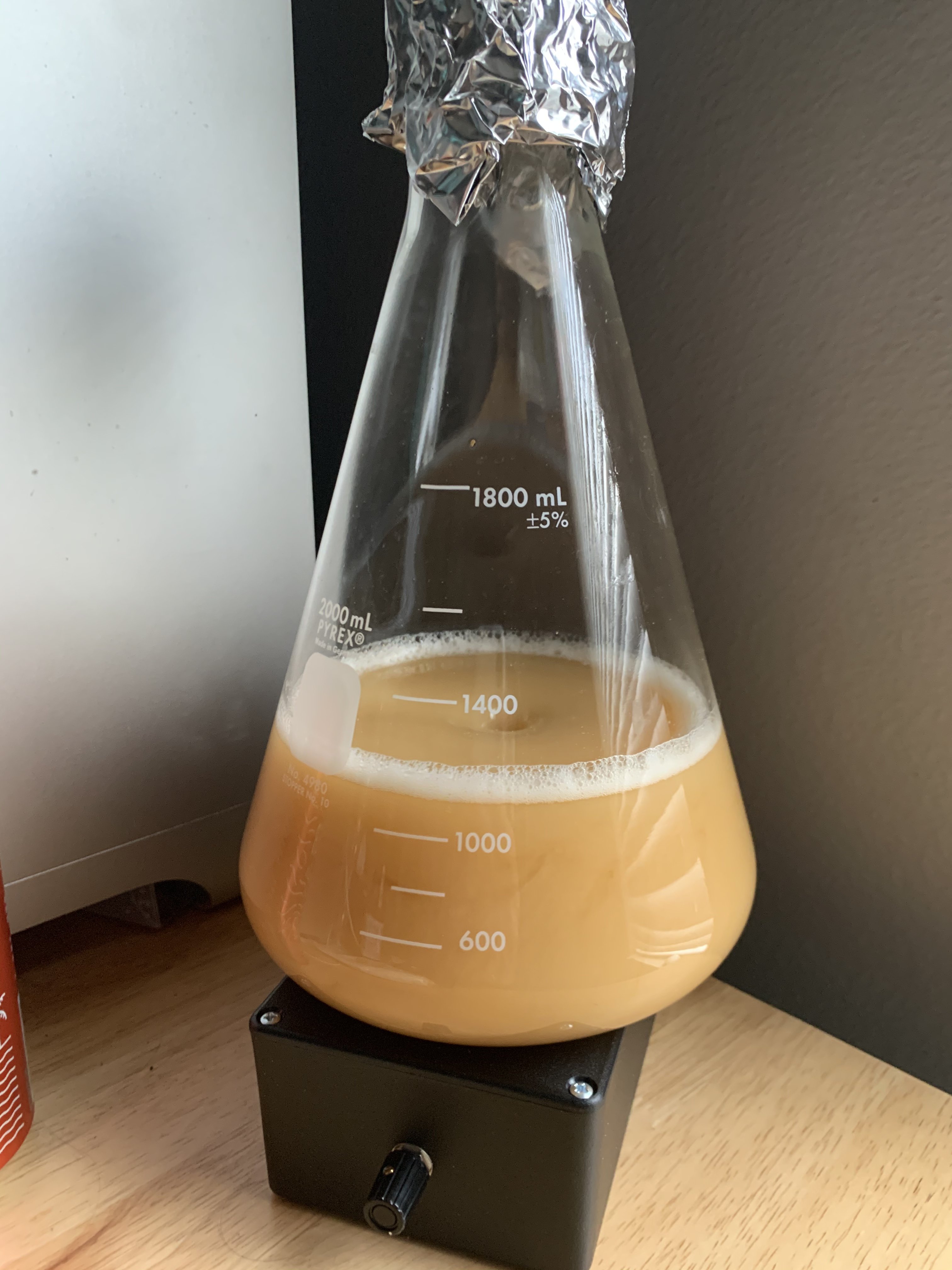

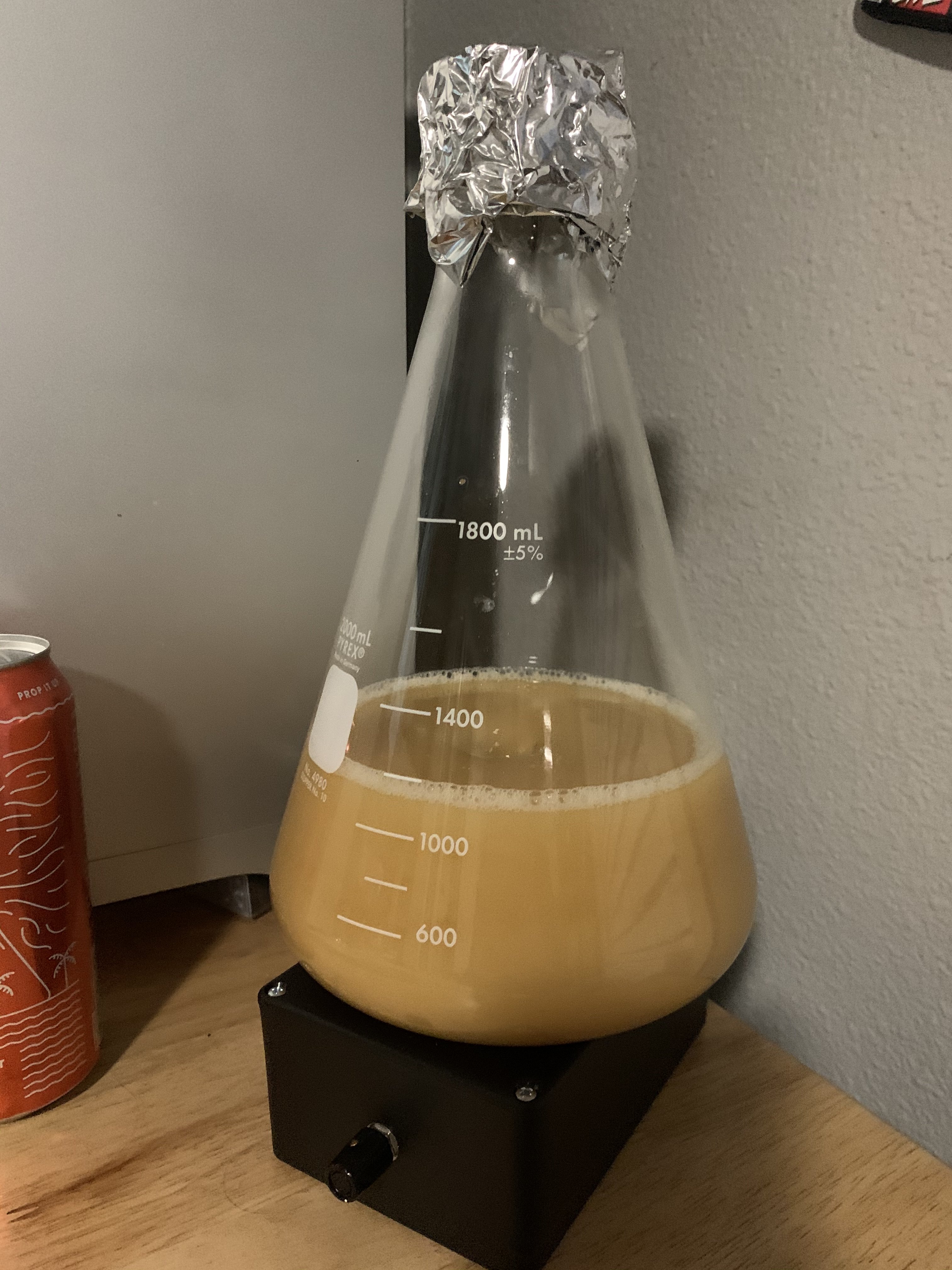

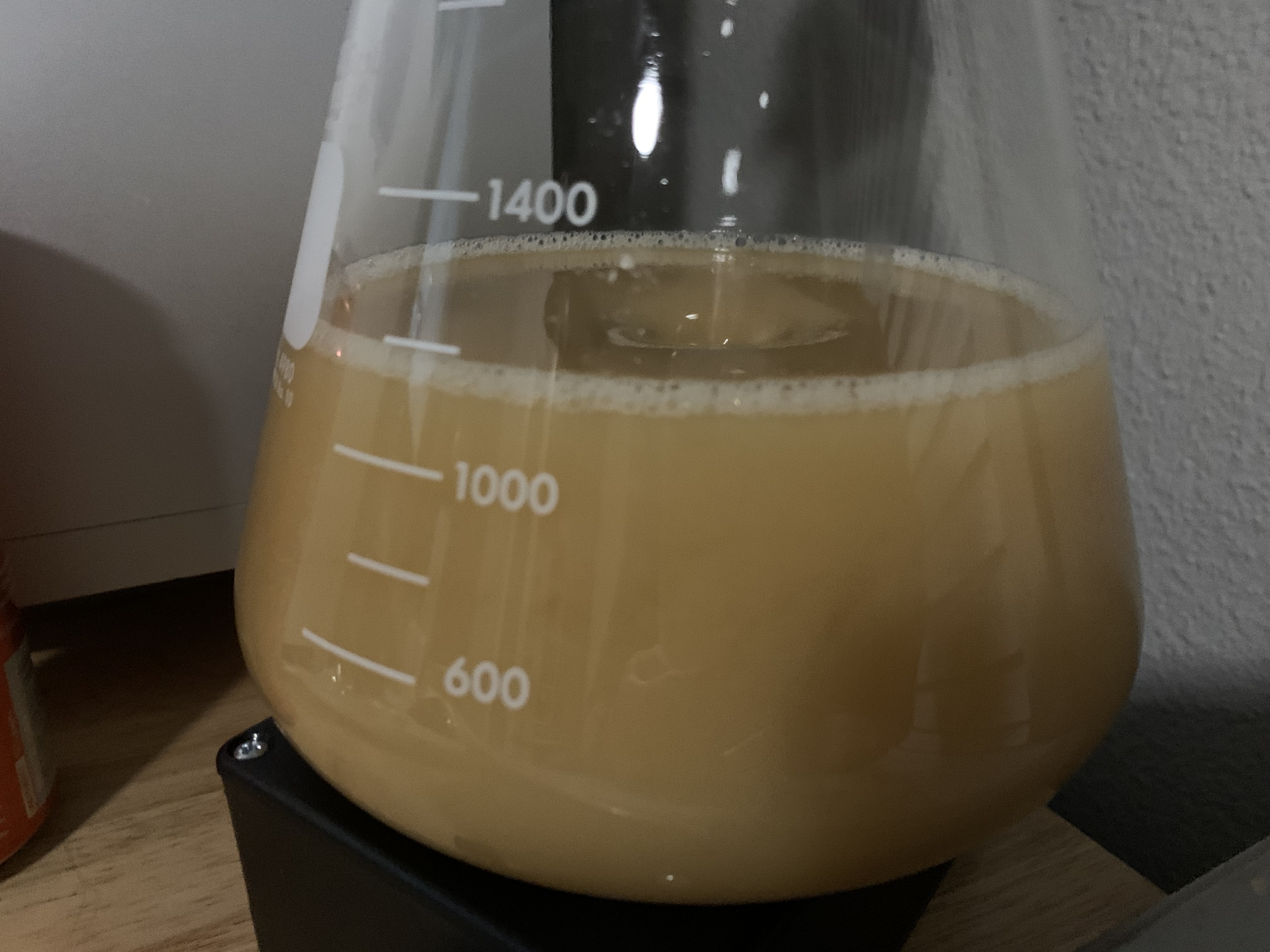

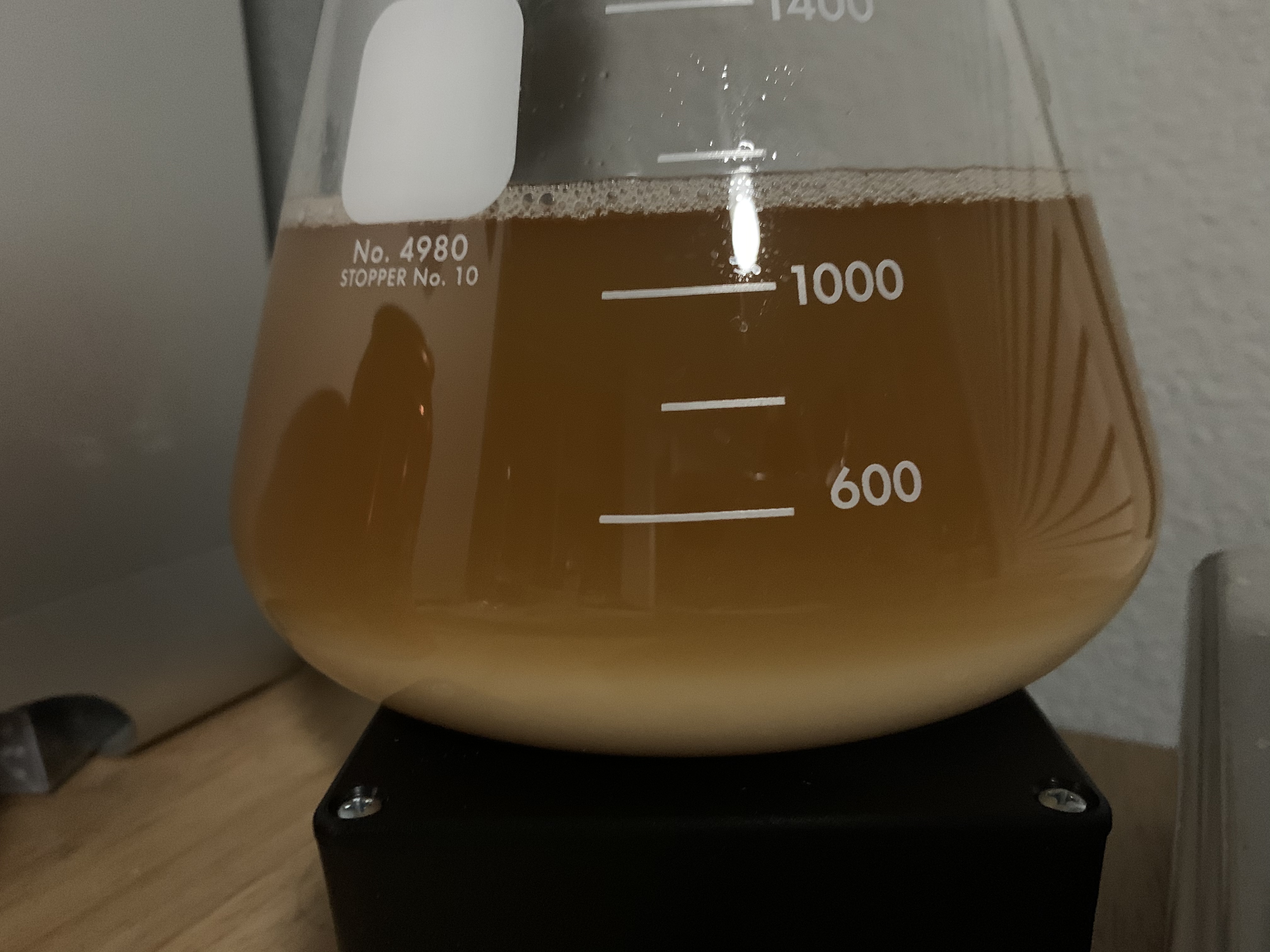

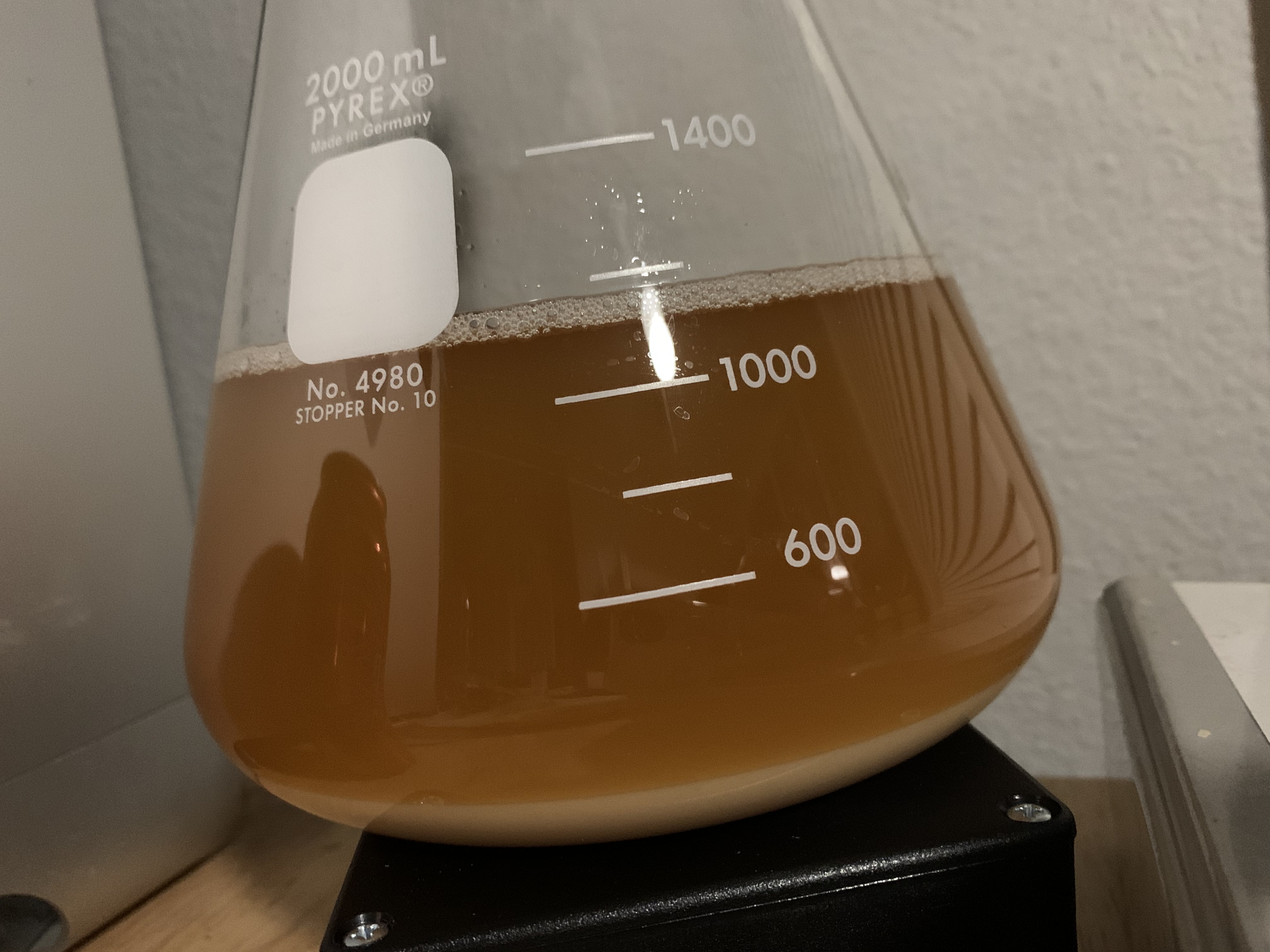

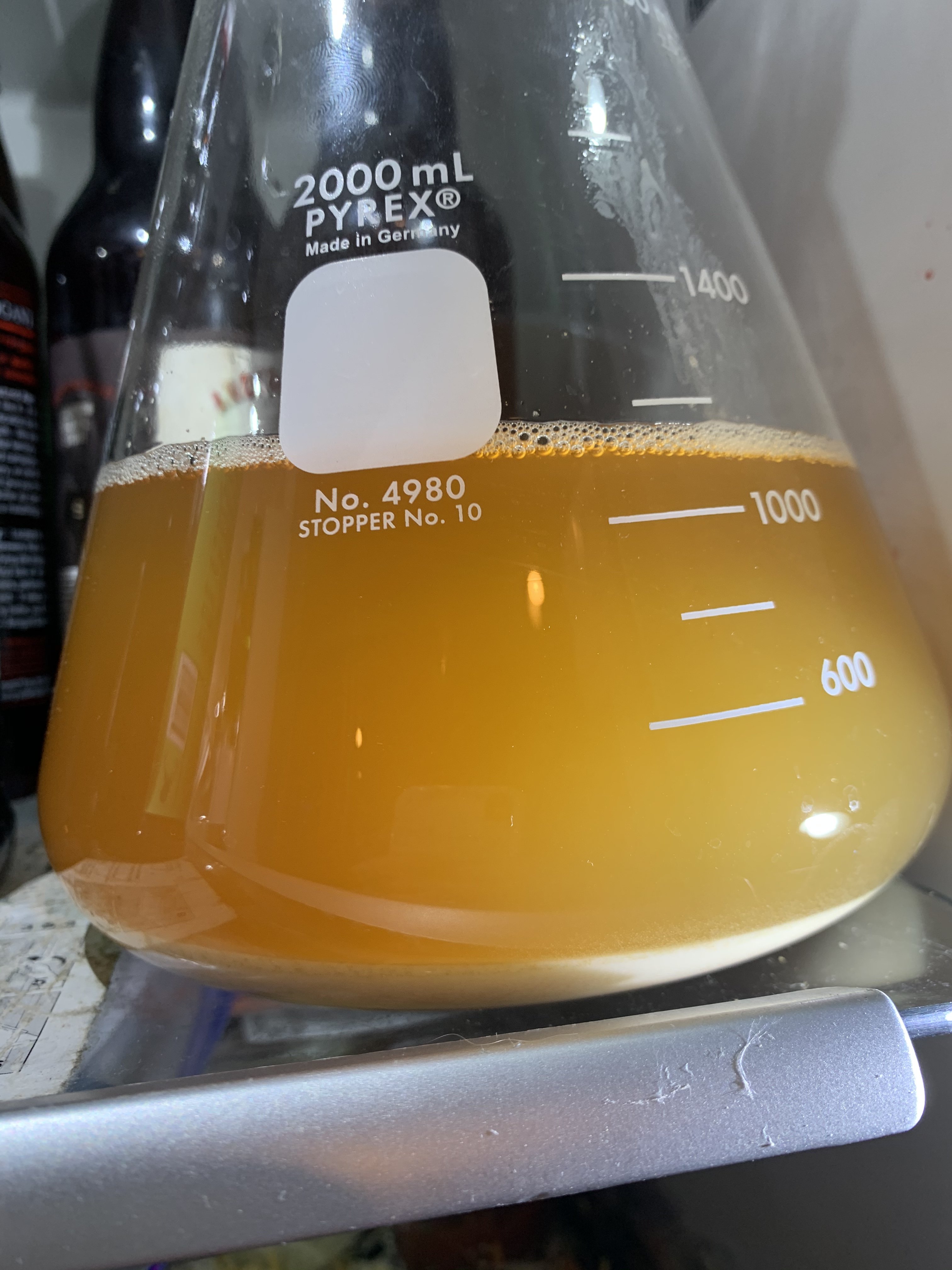

1) Step 1: 1 Liter Stir Plate Starter

2) When Step 1 is finished (attenuated), cold crash and decant.

3) Step 2: Add 1.4 Liters wort, return to Stir Plate

4) When step 2 is finished (attenuated), cold crash, decant, and pitch into your beer wort.

Thanks for this. I started playing around iwth some step calculators. Every one is a bit different.

I'm calculating needing a 1.0 Pitch Rate being that this is high gravity. I'm also assuming 92 Billion initial cell count. Fresh, but not right off the press fresh.

I basically went to a few sites and plugged in what you added.

MoreBeer says I need 540 billion cells. At the end of the second step I would have 509 billion.

BrewersFriend says I need 540 billion cells as well. They say at the end of the second step I'd have 392 billion.

@IslandLizard, I input this information in brewunited and it's pretty darn close to BrewersFriend's output. One thing I don't like about this calculator is that you cannot have seperate starter details per each step. No like-y on that.

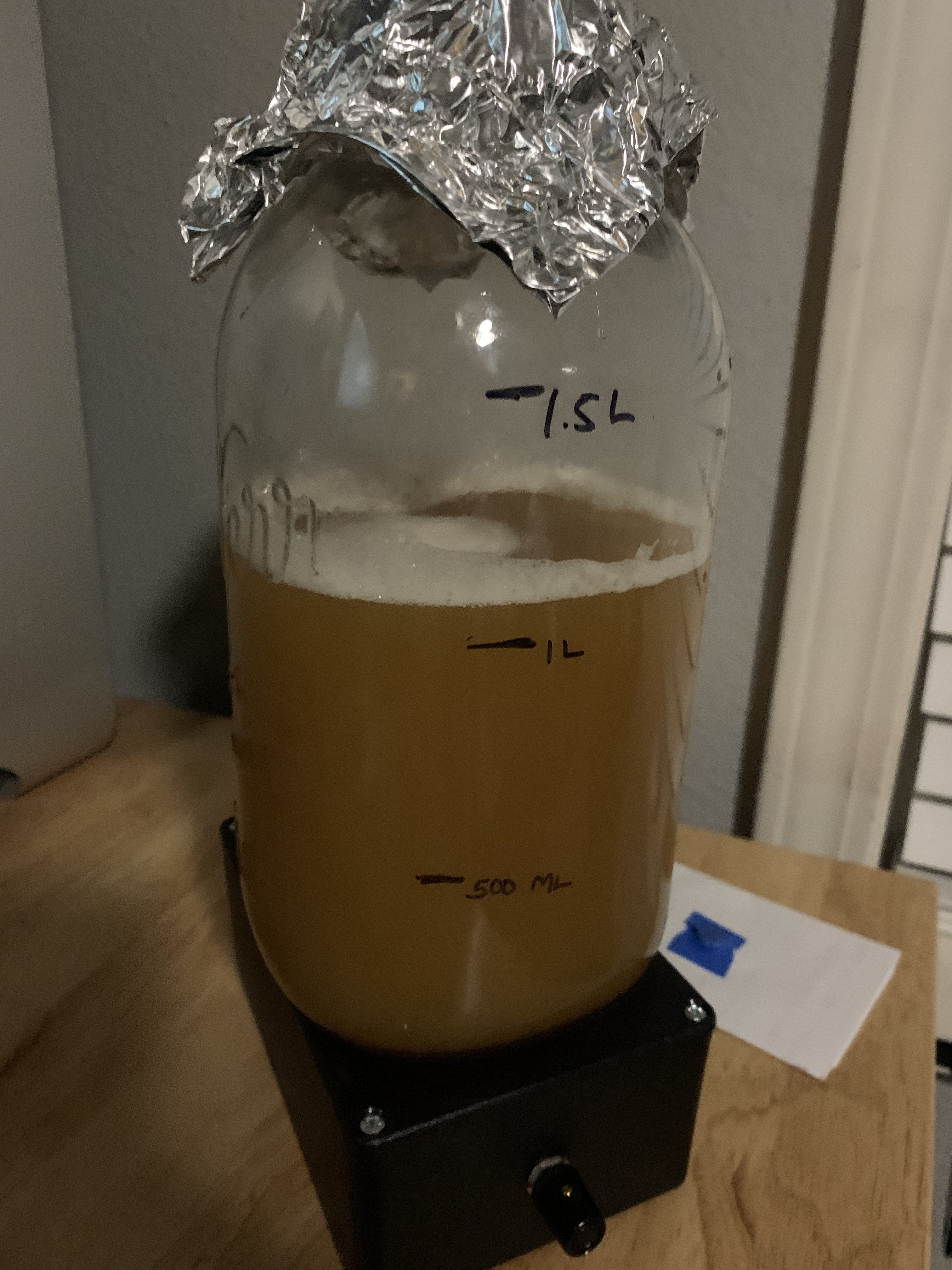

I think I'm going to need a bigger starter here....