fendersrule

Well-Known Member

- Joined

- Oct 11, 2018

- Messages

- 703

- Reaction score

- 341

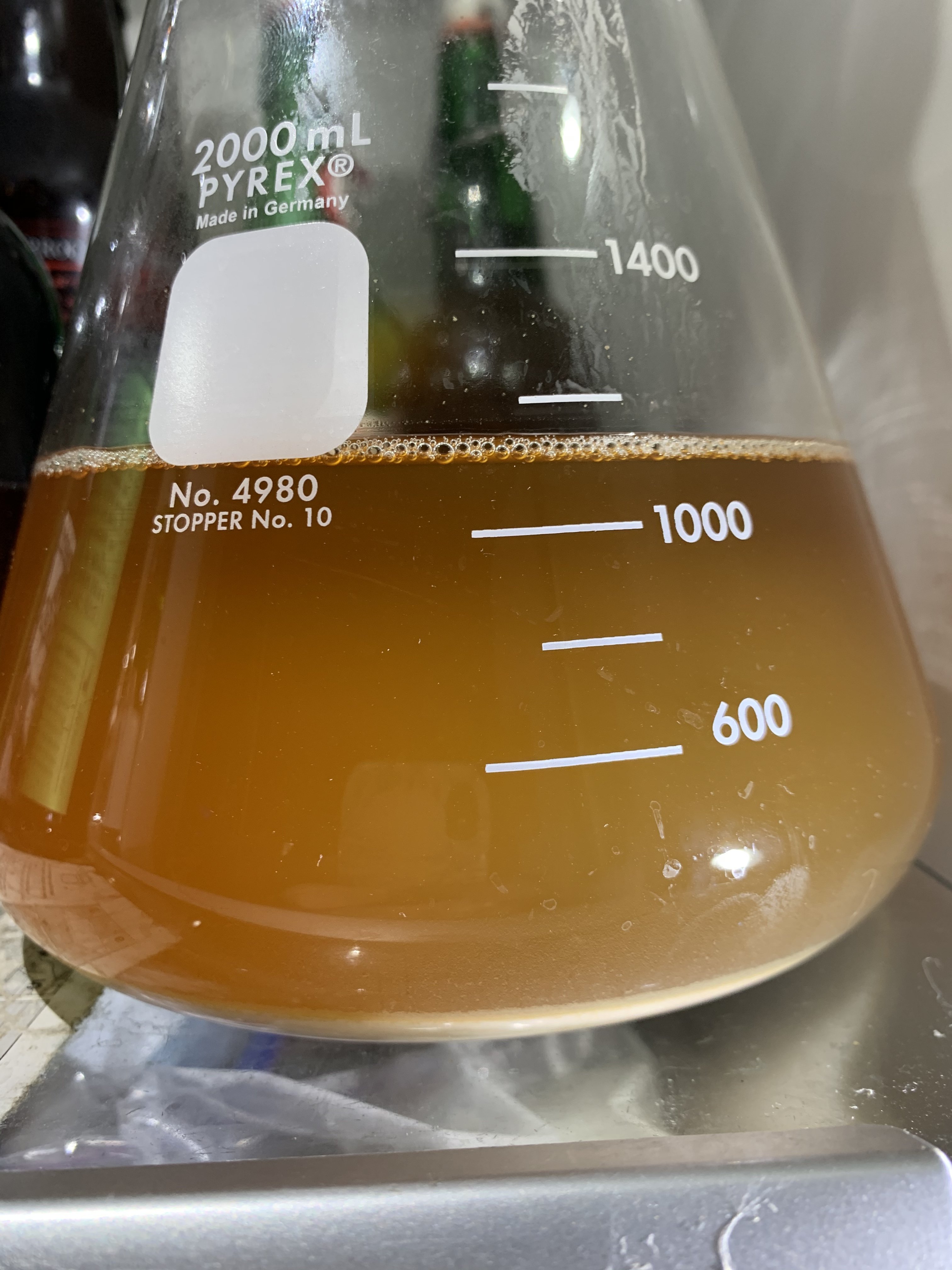

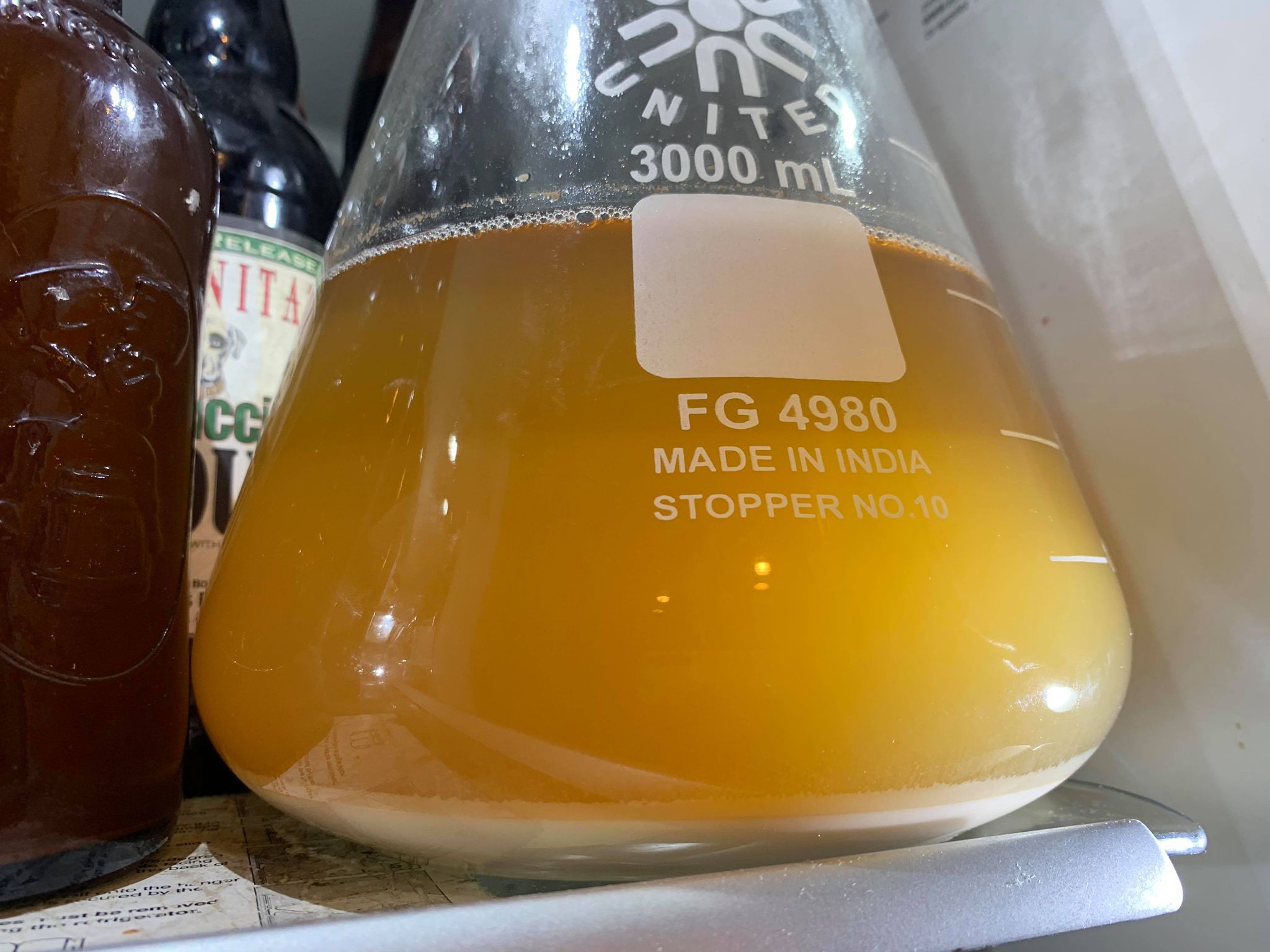

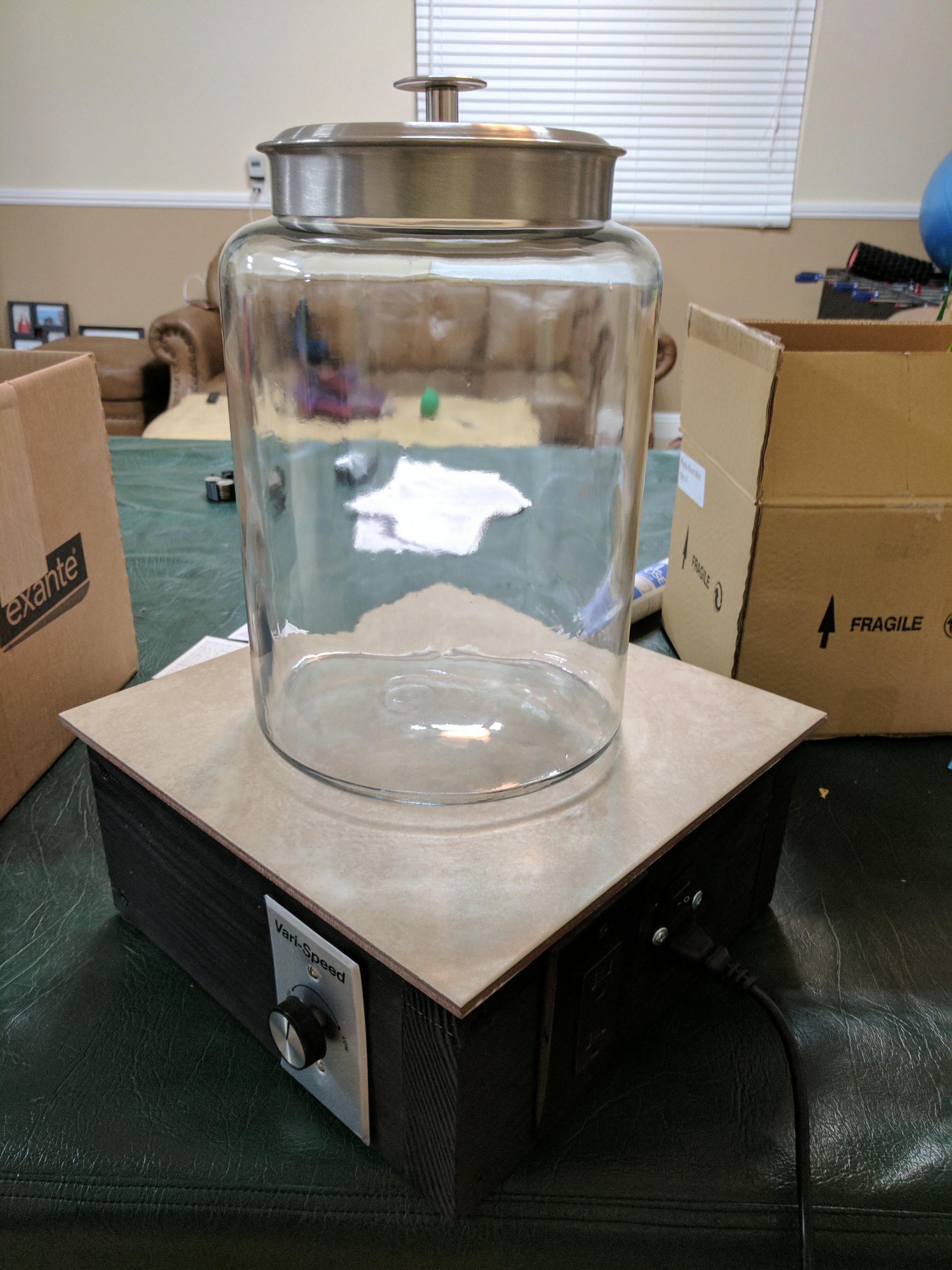

A couple hours on fridge. You can see a difference.

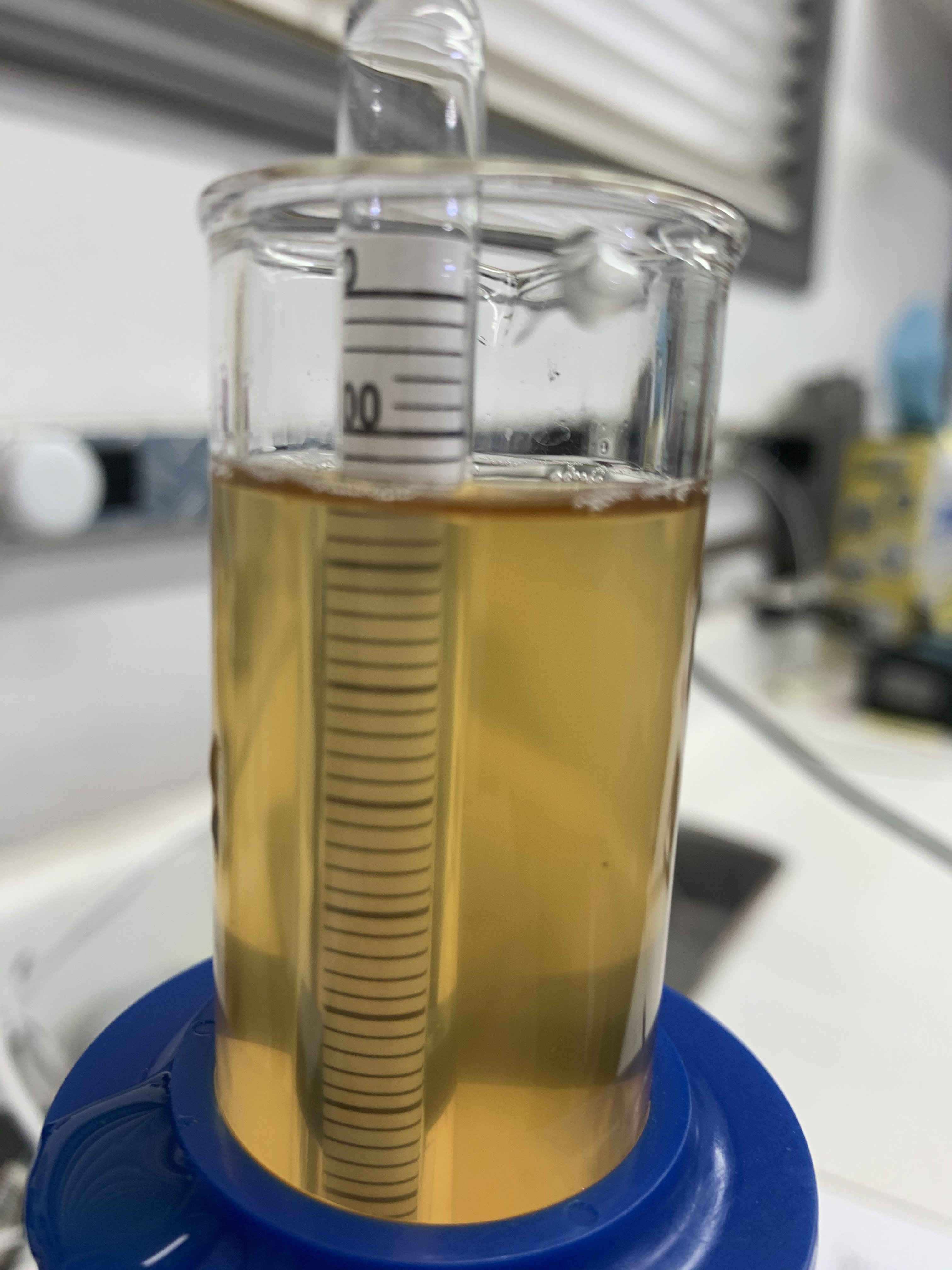

Once you're ready to pitch the slurry, please, don't forget to save out some of the starter beer into a hydrometer jar when decanting.Overnight

Is your batch going to be about ready for the pitch by then?would you guys be tempted to decant that in a few hours?....or atleast do a semi decant?

that pitch rate is like .85 per plato.

I’m thinking to decant just enough to fill up the hydro jar, then shake and pitch the rest. I’ll test the FG for yah!

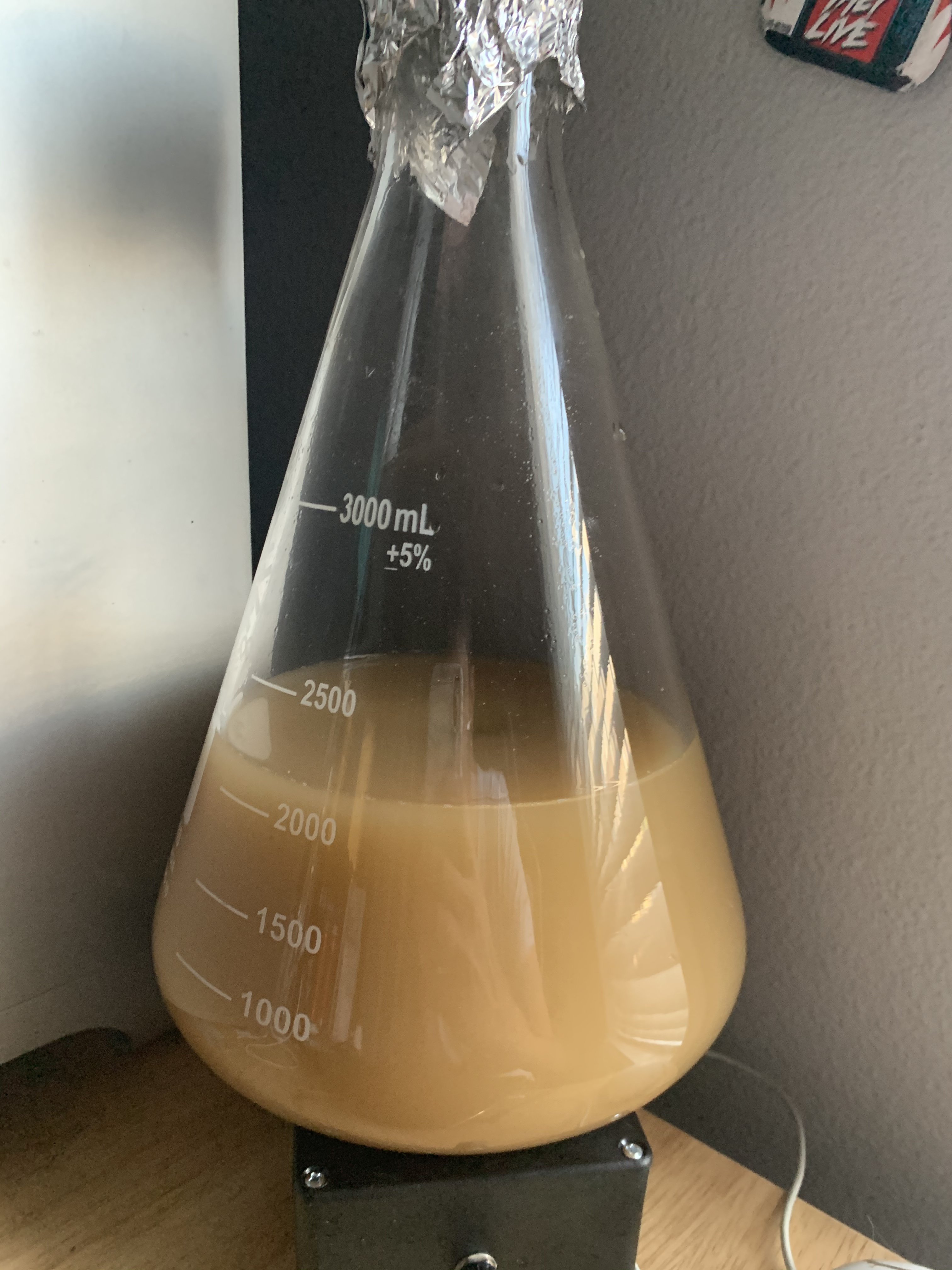

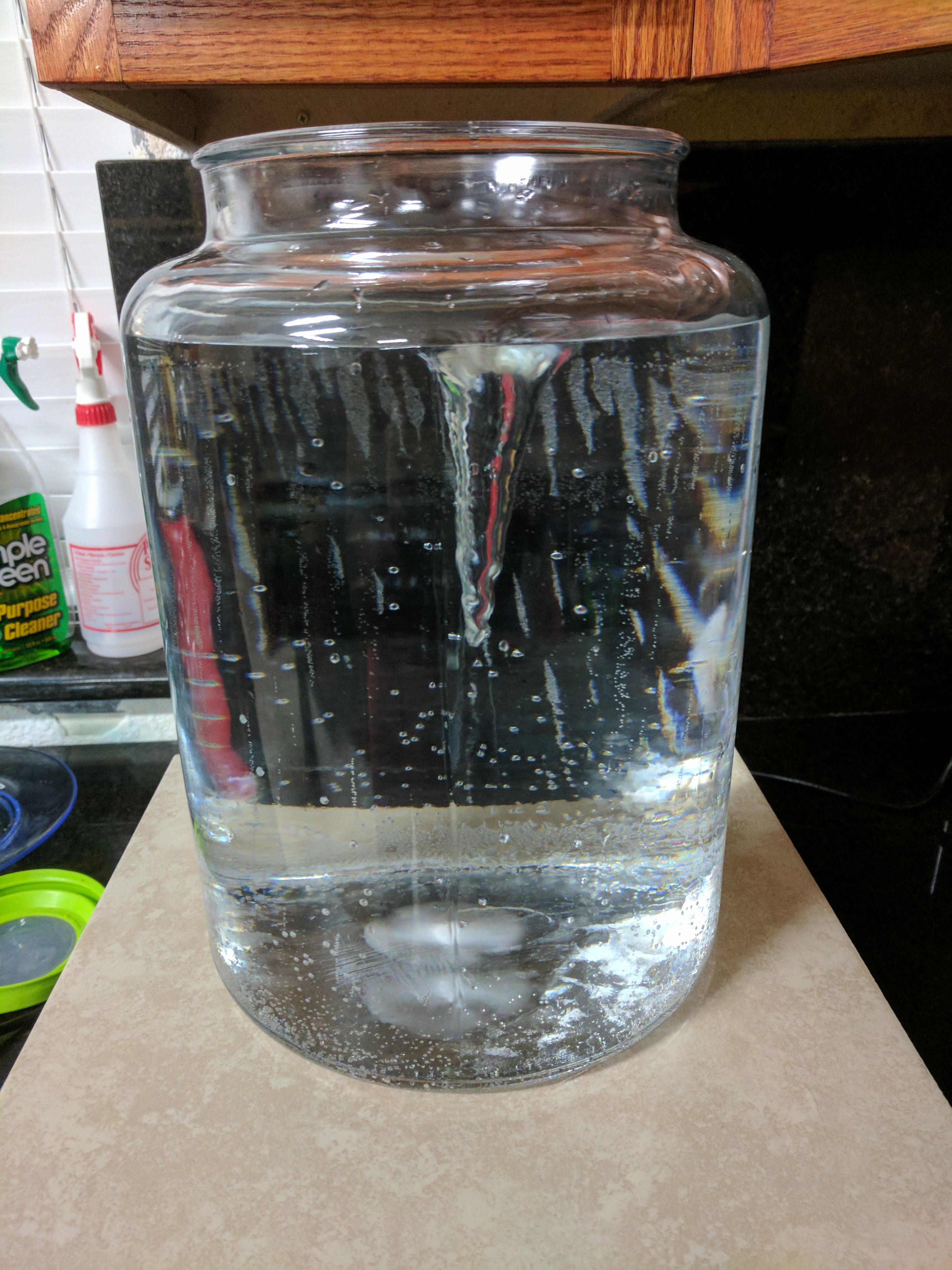

A fresh starter like that can give you lift off in less than 4 hours.Wow. 9AM, or 16 hours after pitching. Usually I see obvious signs o fermentation, but seeing a full roll at this point is awesome.

It probably was full rolling way before 16 hours too.

Looking good!

1/4" ID is not blow off tubing.Correct me if I'm wrong...I worry more about this using 1/4" blow off tubing.

Since it's winter, I may even consider storing this thing in the garage a couple days before bottling....wouldn't hurt right? Wouldn't necessarily buy me anything though.

Then ill have 100million yeast cells ready for brew days.

Can't I just make a US-05 starter to save some costs?

LMAO, yeah my biggest problem is drinking while messaging. Imagine the step up starter i would have to do?!!!100 Billion, perhaps?

Enter your email address to join: