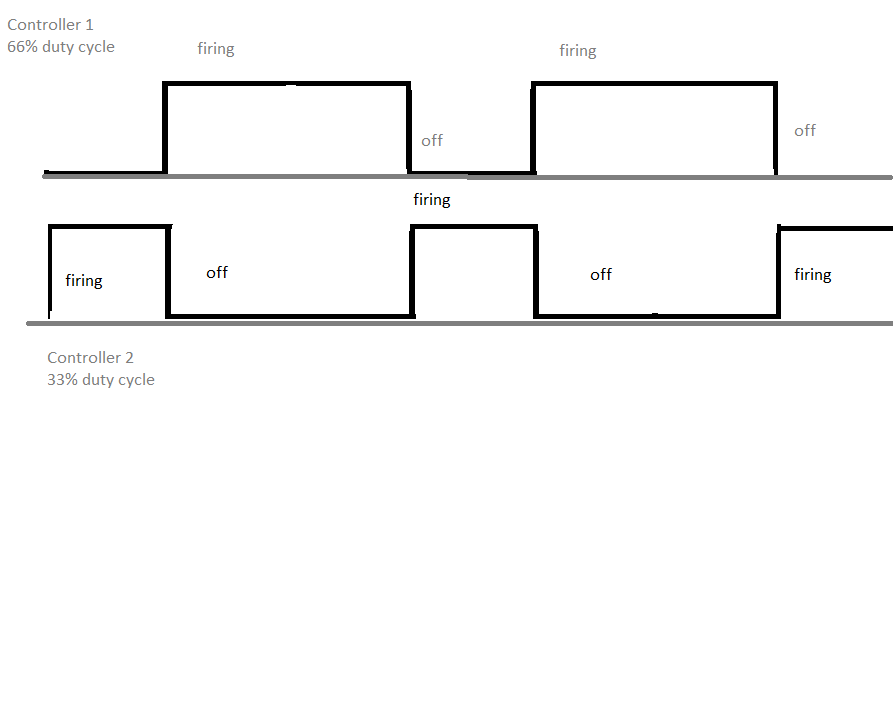

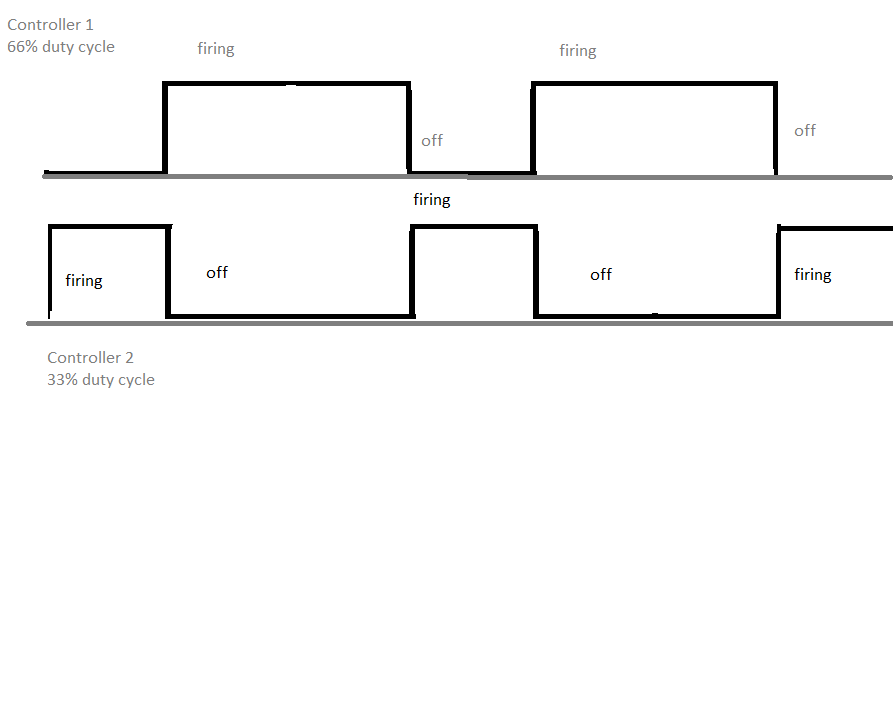

So in a 30 amp system, you obviously cant have both 24A elements firing at the same time. Has anyone wired two PID controllers together so that when both controllers are in PWM manual mode, that they would synchronize so that they fire their individual elements in alternating pulses? in essence having both firing at the same time. and if so, what model PID controllers did you do this with.

Or if there is a way in analog components to force this synchronization? In digital logic this would be very easy to control, but im not as good with analog components yet.

Or if there is a way in analog components to force this synchronization? In digital logic this would be very easy to control, but im not as good with analog components yet.

Last edited: