OneHoppyGuy

Well-Known Member

Center casters will certainly do it.

$100 for casters? OUCH!

Hey Deric, when do I get to see photos?

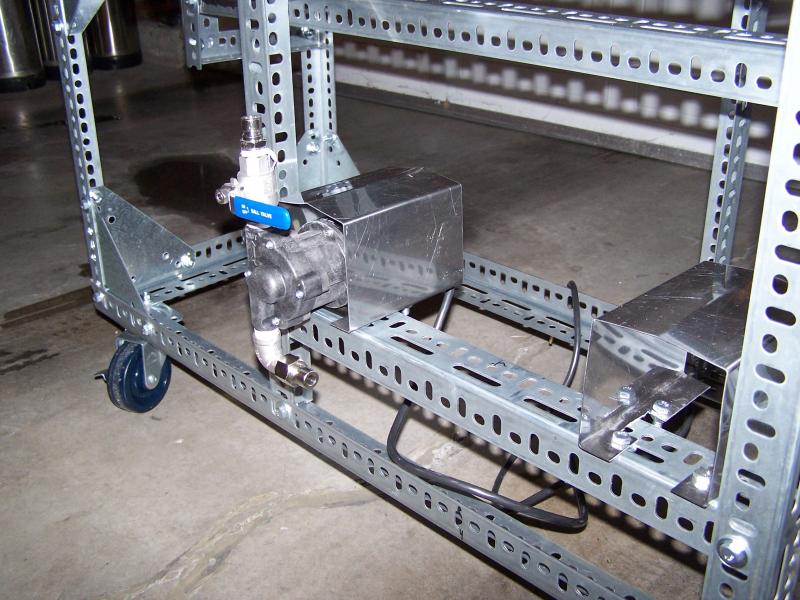

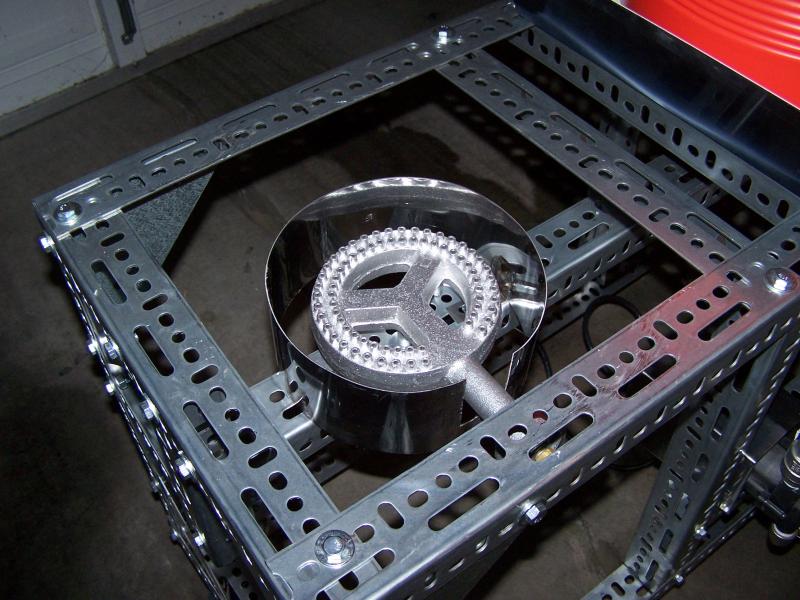

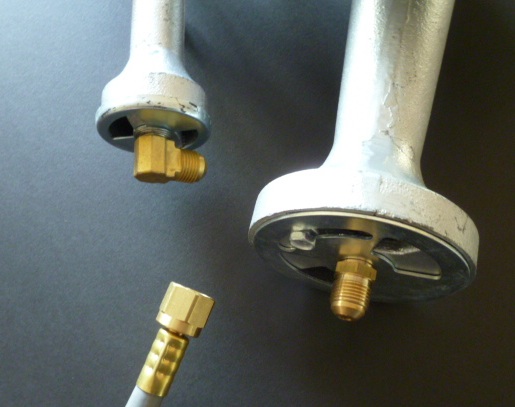

Got my propane manifold built, pressure tested, and then fired up all 3 burners successfully.

ryanmcl said:Dannedry- I would very much like to copy your gas setup. If you would be so kind as to let me know the parts list all the way from propane tank to burner i would be very greatfull. Also, can you tell me where you procured these items? My local hardware store does not seem to have much a selection. I will probably have to buy online.

Thanks!

Dukeman9988 said:Does anyone has a cheap blade suggestion for a miter saw to cut this stuff?

I'm interested as well

SanMarzano said:I got a dewalt blade at lowes for a 10" saw for 11 bucks

Good catch!

Where did you get your valves?

Here's what I have so far..... Keggles are welded. They need to be scrubbed but it was too damn cold out today... Have all the fittings (I think) Sightglasses should be here in the next couple days. Cooler that I bought 10 years ago (literally) to use for a mash tun is FINALLY done. Would like to come up with a shelf to put in the bottom. Still waiting on the gas manifold, second pump, pump switch box .... and I'm sure I'll find a few more things.....

What did you make your pump shields out of?

Metal cutting blade?

OneHoppyGuy said:The fitting on a BG14 is 3/8"

Quick question, is there a reason why you couldnt just use the 1-1/2" x 1-1/2" pieces for everything instead of switching to the 2-1/4" pieces

My wife just gave me permission to order this steel for my Valentines present! I'm so happy!

I hope you're getting her something nice...

Just ordered the pieces! So stoked about this. My question is are there actual plans as to how long the cuts are?

ryanmcl said:I got the burners on amazon for about $7 more per burner. I made the manifold using a lot of input from this thread.

Enter your email address to join: