BrewBeemer

Well-Known Member

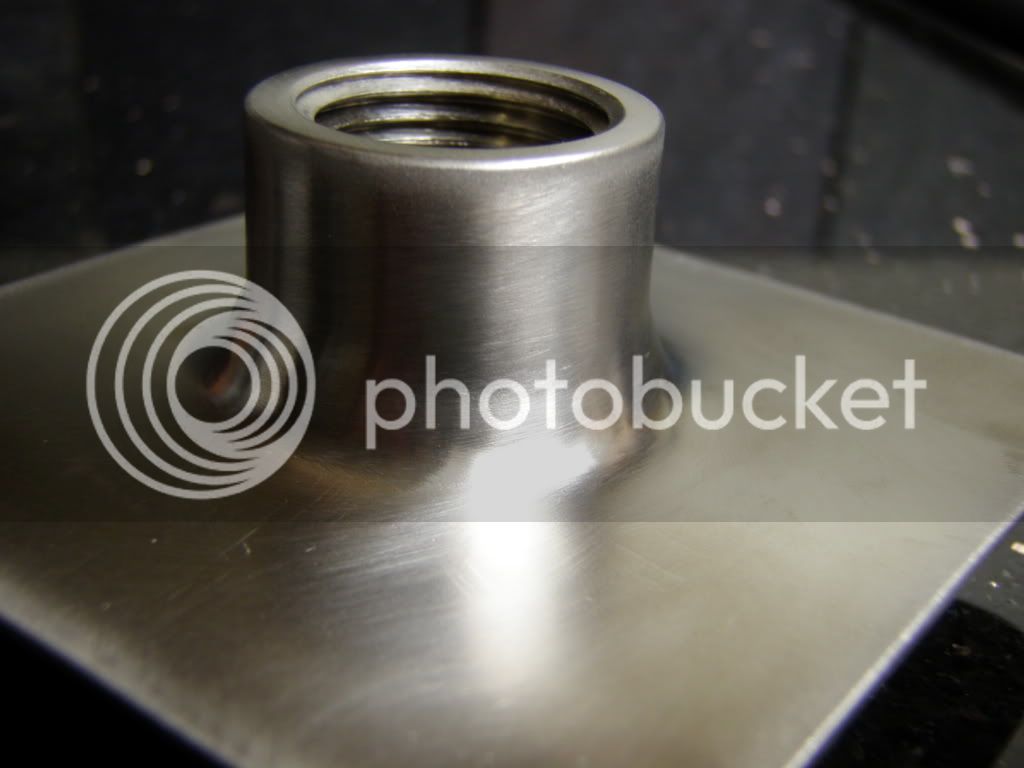

OK, so unless I can find someone to make me a "Friendly" deal, looks like I might be in the $150-$200 range for welding up my kegs.

Another question...

With the right equipment, how tough would it be to weld this myself?

(And I really don't mean any disrespect to the guys that do this professionally... I know it takes years of experience for this to be second nature and know how to deal with any situation that comes your way)

Obvious next question...

What would be the right equipment for a home owner and avid DIYer and what kind of cost are we talking about?

Ed

Think of it as a investment and lifetime tool a Tig welder.

If you get lucky and find a used 250 Miller Synchrowave in good condition you can not go wrong as you can get your money back if you sold it.

I found a cherry 1994 250 complete with 150 cu/ft owner own bottle, torch, regulator and Victor ball flow meter for only $850 last year for a friend. It has paid for itself many times over already and will be never for sale he's very happy with it. he got the Miller Tig bug after practice on my 350 Synchrowave, before this off El Cheapo imported Tig welders with 20% duty cycles. That alone about finished his desire to learn to Tig weld and invest in a welder. The Miller Diversion 165 Tig for $1,275 is at the lower end of amperage and duty cycle of 20%. If looking at new welders www.Cyberweld.net has prices way below MSRP Miller units included plus free shipping. Out of state no tax either. Take night classes you'll be surprised the projects you'll be building.

I was thinking of Jaybird. That is if he is in redding.

I was thinking of Jaybird. That is if he is in redding.