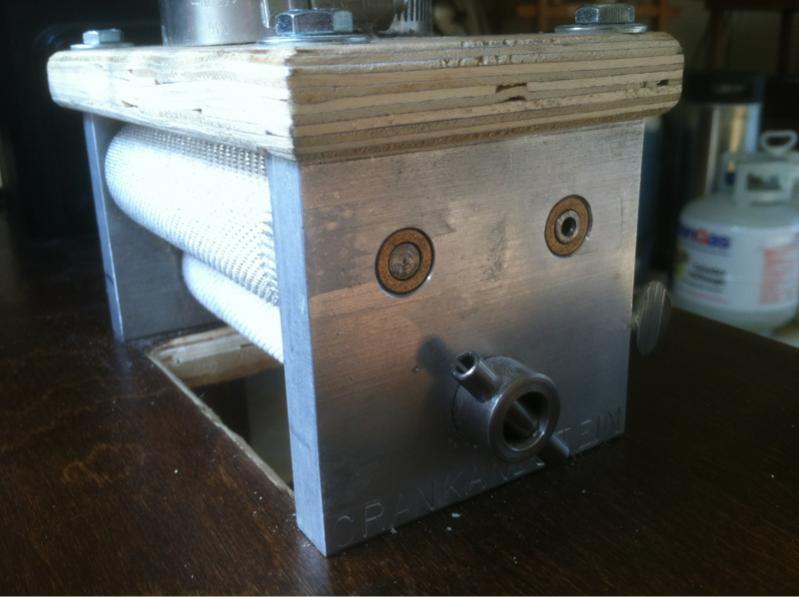

This is a project that's been on the back burner a while (like most of 'em). While I've had my Crankandstein 3 roller mill motorized for over a year now, it's been a pretty crude setup: all mounted to plywood that I'd setup on sawhorses when needed. Figured it was time to work on a dedicated cart for it.

Here's the older thread that leads up to this one:

https://www.homebrewtalk.com/f51/shiny-new-mill-motorize-not-motorize-216710/

Pics of my progress so far coming up in my next post.

Here's the older thread that leads up to this one:

https://www.homebrewtalk.com/f51/shiny-new-mill-motorize-not-motorize-216710/

Pics of my progress so far coming up in my next post.