I used to use a Superior 1/4HP sump pump to run cleaner through my beer lines. It did good for about 6 years before I noticed it was leaking oil one brew day. I used it that day to recirculate ice water through my plate chiller (lucky I wasn't using it for cleaning beer lines that day) to chill my wort closer to pitching temps.

The past few months, I'd been using CO2 to push rinse/cleaner/sanitizer through the lines until I get another pump. My cousin recently got a Riptide which replaced his old Steelhead pump, whihc I now have and thought about using for line cleaning duties. The only issue I see is priming the pump, which I can deal with.

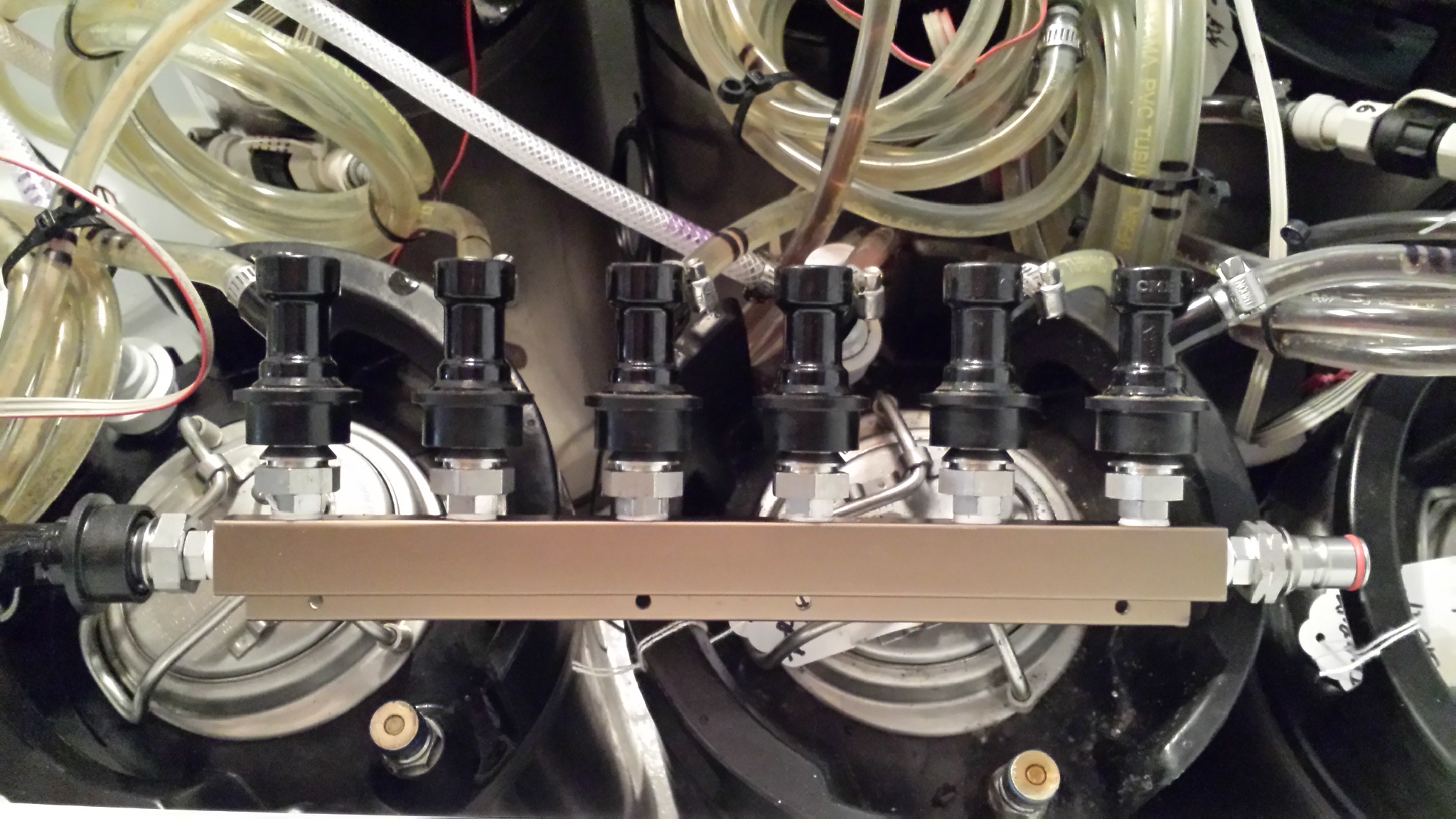

Another issue I'm concerned about is push fit connectors (aka John Guest). I don't have them, but I have been looking at them as well as going with Accuflex beer line to replace what I have. Has anyone been using this style of pump with those type of fittings? Thanks in advance.

The past few months, I'd been using CO2 to push rinse/cleaner/sanitizer through the lines until I get another pump. My cousin recently got a Riptide which replaced his old Steelhead pump, whihc I now have and thought about using for line cleaning duties. The only issue I see is priming the pump, which I can deal with.

Another issue I'm concerned about is push fit connectors (aka John Guest). I don't have them, but I have been looking at them as well as going with Accuflex beer line to replace what I have. Has anyone been using this style of pump with those type of fittings? Thanks in advance.