abrewer12345

Well-Known Member

- Joined

- Nov 30, 2015

- Messages

- 121

- Reaction score

- 18

can someone just explain to me how to come up with the sulfate to chloride ratio. our base water is below, along with the target (NEIPA) and final. thanks for any help!!

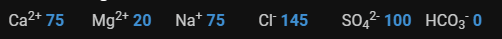

base water :

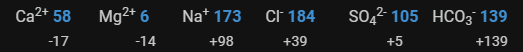

NEIPA Target :

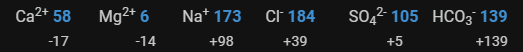

Final Water :

getting there with 4g of gypsum, 4g of calcium chloride and 2g of epsom salt- add in a campden tablet and 4oz of lactic acid and 2% acidulated malt to the grain bill. pH hits 5.41

base water :

NEIPA Target :

Final Water :

getting there with 4g of gypsum, 4g of calcium chloride and 2g of epsom salt- add in a campden tablet and 4oz of lactic acid and 2% acidulated malt to the grain bill. pH hits 5.41