Thanks I get the idea now.

I might have another solution, I see there is a 6 and 7 gallon version of the fermonster.

I have the 7 gallon version and the 6 gallon one is apparently 2 to 2.5 inches shorter.

Hopefully it's big enough to get a full 5 gallons of beer for the keg.

I found a shop that is selling them online for 16.99 € in Germany- stock clearance.

Thats about half price compared to other shops, the only thing is they have no lids without a hole left.

I could use the lid I have already prepared but maybe I want to make a second one.

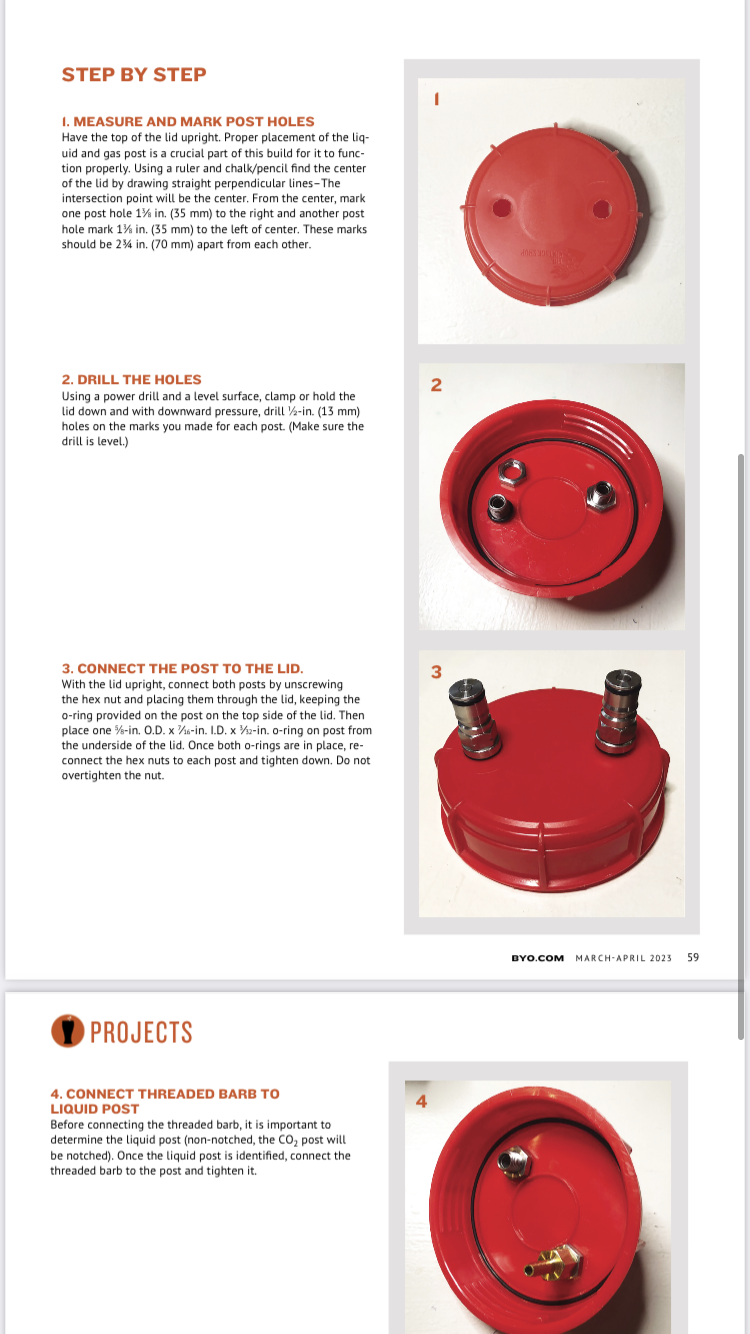

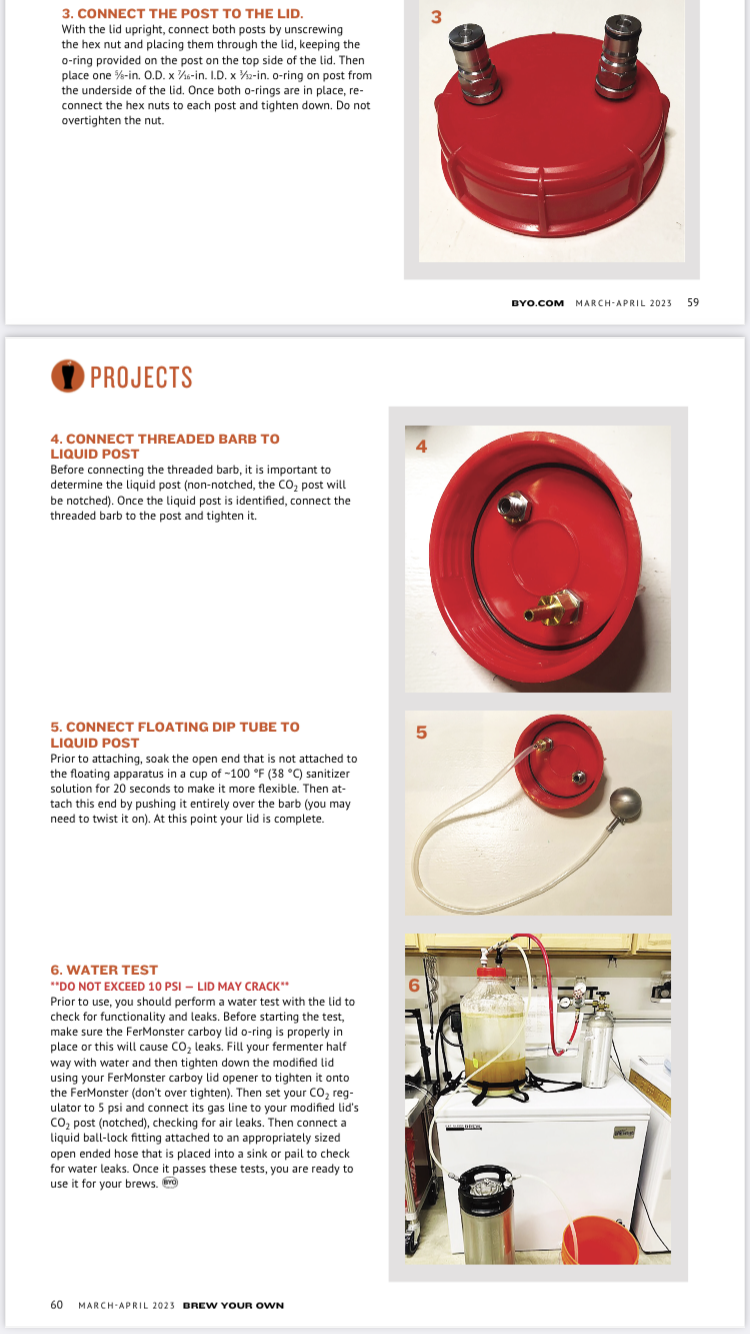

BTW looking at the BYO article I did it slightly different, I added a 3 inch dip tube to the gas post - cheaper than a barb and less screwing around but maybe i might want to add a clamp around the tube just in case.

Edit: just saw your point about the grooved locknut - mine is smooth but appears to be airtight.

If I have problems maybe I could add a grooved washer inbetween instead of replacing the nut.