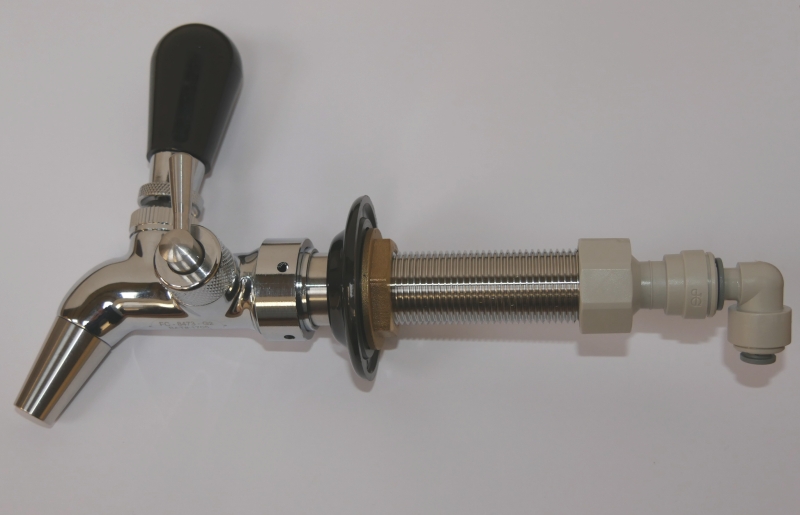

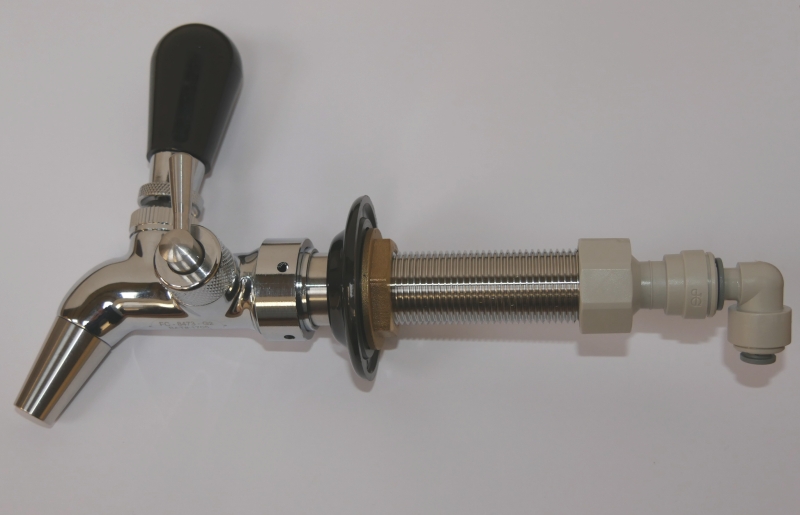

I've been thinking about that same setup too, using JG fittings, like you want to do.

Freshwater Systems doesn't seem to have a 90° BSPP adapter, so you're always stuck with connecting those 2 together.

Have you measured the "net length" of the BSPP + 90° adapter? If that's less than 3" there "may be" enough space inside the tower.

But there's definitely NO thread left on the short tower shank after the nut is on to even attach the BSPP onto. Unless you want to try to rely on the BSPP fitting itself to secure the shank at the same time as sealing it. In that case you could always add a washer or 2 to get enough tension. But relying on a plastic threaded fitting to secure the shanks is very gutsy! When you pull the handle or bump the tap all the stress is on that plastic fitting.

Solution:

I think the best and simplest way is to have a short piece of regular (thick walled) beverage tubing over the tower shank's barb. Then use a JG adapter to connect your Ultra 235 line to that. The shorter you keep that regular piece of tubing, the less it will influence your Ultra 235 system. A 3/4 - 1" piece of tubing extending from the barb's end should be plenty.