treacheroustexan

Well-Known Member

Can anyone recommend a good, absolutely free 2d cad program I can use for work?

First thing that comes to mind is sketchup, but without knowing what you want to do with it...Can anyone recommend a good, absolutely free 2d cad program I can use for work?

First thing that comes to mind is sketchup, but without knowing what you want to do with it...

I have sketchup in mind, but really no specific purpose. Random projects. Stairs, blow molding machine parts, plumbing.. Just kind of whatever project I have going on at the time haha.

I have sketchup in mind, but really no specific purpose. Random projects. Stairs, blow molding machine parts, plumbing.. Just kind of whatever project I have going on at the time haha.

Can anyone recommend a good, absolutely free 2d cad program I can use for work?

Thought some of you guys might be interested in this. 3d printing from your smartphone.

I am a backer on kickstarter.

https://www.kickstarter.com/projects/olo3d/olo-the-first-ever-smartphone-3d-printer

Holy hell, mind blown!!! That is incredible. I really want to get one, but I cannot justify it as I already have a RepRap printer...

Thought some of you guys might be interested in this. 3d printing from your smartphone.

I am a backer on kickstarter.

https://www.kickstarter.com/projects/olo3d/olo-the-first-ever-smartphone-3d-printer

That thing is pretty slick. If my friend (who constantly eats my food and drinks my beer) didnt have a 3D printer that I had access to (I make tap handles, he drinks my beer), I would buy one. But still pretty freaking cool

Yeah mind blown but it seems to good to be true. The videos are absolutely incredible lol. I may end up canceling my pledge and waiting for the official release. I don't see it actually shipping in september like it is estimated. But then again, for $99 what is there to lose? (other than $99)

Which printer do you have? I'm looking to (not buy one yet) but learn more about it and maybe get one in a few years.

Never thought about the tap handle idea. I might have some work to do...

I printed a ton of these for my brewing friends:

View attachment 350148

Here is the Thingiverse page for the .STL file:

http://www.thingiverse.com/thing:1286779

Never thought about the tap handle idea. I might have some work to do...

I don't like the idea of "cloud" programs, but I may have to check that out.

I have a yearning desire to make a 3D model of my house, but I don't have time at my work PC. And some of the other programs **cough** sketchup **cough****cough** leave a lot to be desired for me.

I don't like the idea of "cloud" programs, but I may have to check that out.

I have a yearning desire to make a 3D model of my house, but I don't have time at my work PC. And some of the other programs **cough** sketchup **cough****cough** leave a lot to be desired for me.

I don't like the idea of "cloud" programs, but I may have to check that out.

I have a yearning desire to make a 3D model of my house, but I don't have time at my work PC. And some of the other programs **cough** sketchup **cough****cough** leave a lot to be desired for me.

I feel the same way about cloud software in general, but for private, personal use, it's great. (Unless you care about privacy in some cases...)

If you are familiar with 3D design software, and especially Solidworks, I really recommend OnShape. It's basic "Create a sketch on a plane, draw a shape, extrude that shape, and voila!" Tutorials in OnShape are not GREAT IMO, but I didn't really follow the basic tutes since I already know the basics of SW. I was able to jump right into it and get frustrated with the tutes related to mating (which could be geared more toward those who don't know all of the terminology, and just better edited in general IMO.)

If I get a chance I'll post a pic or something of one of my models. I *really* want to build a small BIAB rig, but I have a few projects that need to be done up before I can start. I might just spend a little time here and there cutting steel and gathering the parts. I can cut the pieces out at work. My Harbor Fright Chop Saw sucks beyond belief, but we have band saws as work that are nearly automatic. (I really need to fix or toss that stupid HF POS...)

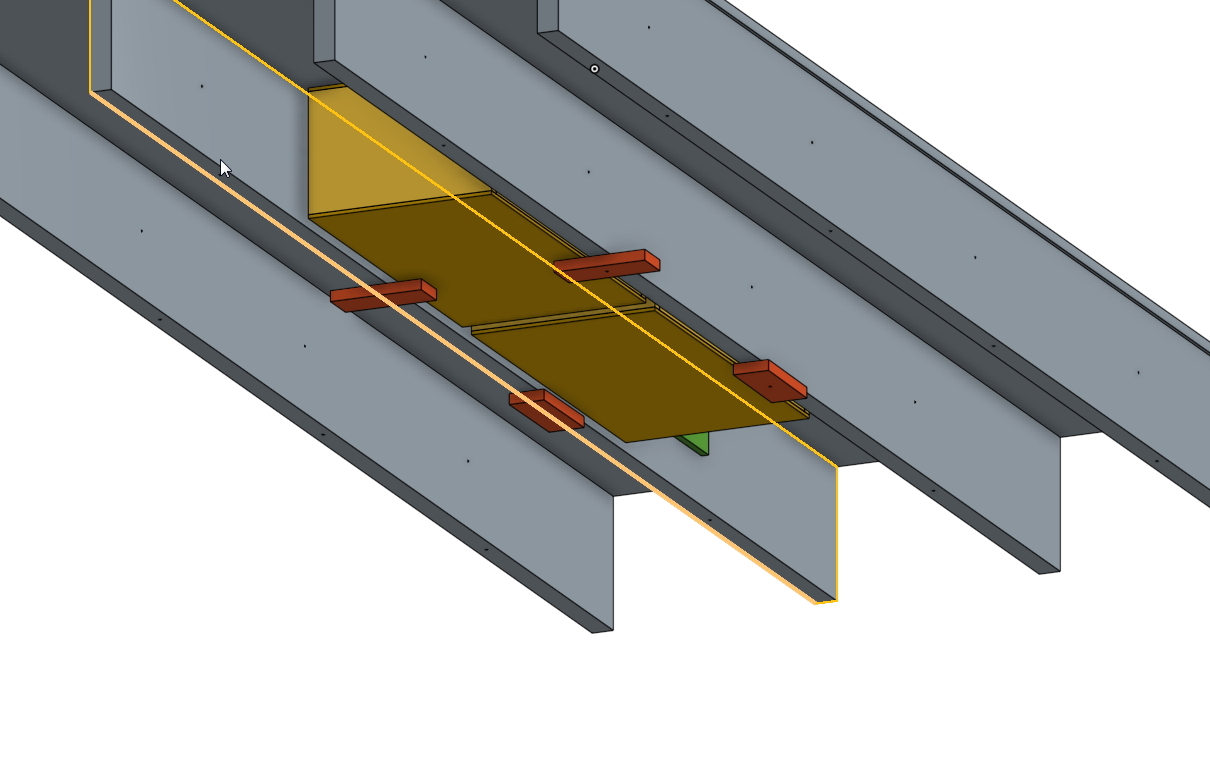

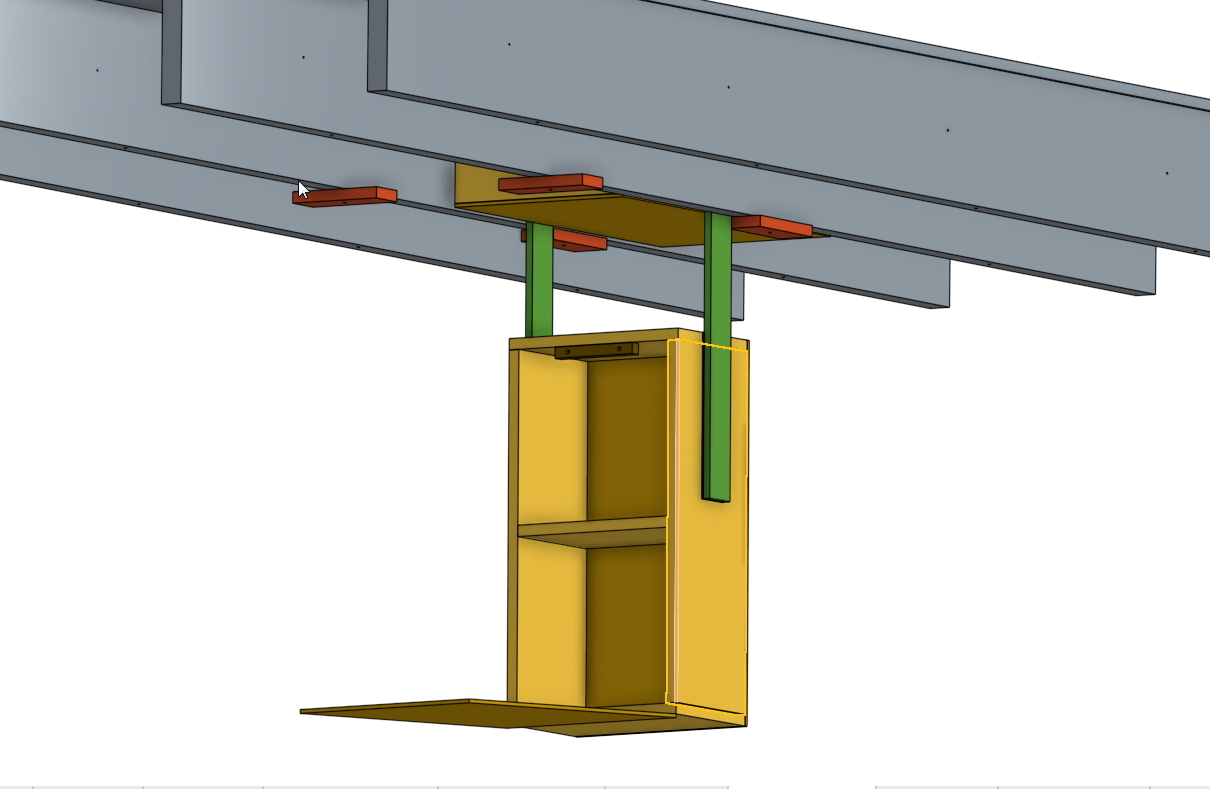

You can get trial versions of a lot of the programs, but SketchUp is actually a great program. Once you start getting into it, it can be a great tool. This rendering was done with SketchUp and twilight render, but I have recently upgraded to lumion as a renderer

Yeah I know lots of people do great things with Sketchup. I'm just too ingrained in other 3D modellers and Sketchup is just a enough different that I need to sit down and try to learn it. Rather than just messing with it for 10 or 15 minutes every year or so

I messed with it a little bit this morning. It does behave similarly to Solidworks. Which is half the reason I couldn't use Sketchup; just too different.

It took me a LONG time to figure out how to rotate the model. RMB? Hmmmm

Enter your email address to join: