Esmitee

Well-Known Member

I want to mount a 2" TC Ferrule to my kettles for an element connection.

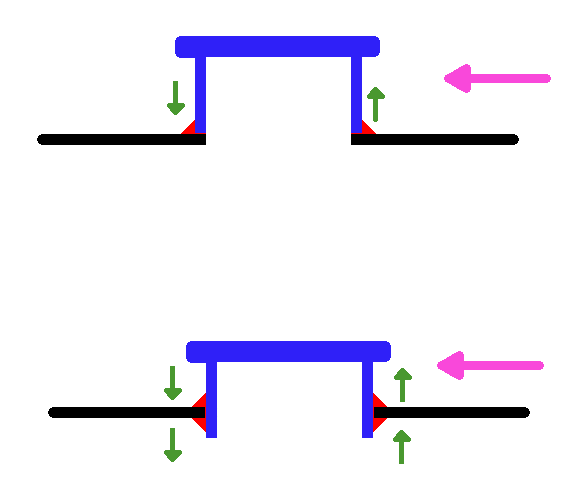

OD is 2", ID is 1 7/8", would it be better to pop an 1 7/8" hole and "butt" the Ferrule to the wall of the kettle and weld or silver solder it on from the outside (with out a dimple), or pop a 2 " hole and push the Ferrule in the hole in the wall a little bit and either weld or solder it? I'm leaning towards the silver soldering, because I can do the soldering myself. Either way be just as strong?

Thanks

OD is 2", ID is 1 7/8", would it be better to pop an 1 7/8" hole and "butt" the Ferrule to the wall of the kettle and weld or silver solder it on from the outside (with out a dimple), or pop a 2 " hole and push the Ferrule in the hole in the wall a little bit and either weld or solder it? I'm leaning towards the silver soldering, because I can do the soldering myself. Either way be just as strong?

Thanks