bucketheadmn

Active Member

I brew 2.5 gallon BIAB batches and ferment in a 5 gallon siphonless wide mouth bubbler. I know that the beer I am making tastes great as I have bottled a couple of batches and they turned our really good.

So I am three batches into kegging and I am drinking flatish beer. I have read quite a lot of how to carb, but hoping someone can point to the error in my ways. When done with fermentation I hook up my hose to the fermentor and then rack directly to my keg. For my keg set up I am using a ball lock corny keg with 10 feet of 3/16" connected to a picnic tap in a fridge in the mid 40's. Here is what I did with each of the three batches:

1 - I set it at 30 psi for a few days and then dialed it down to 10 leaving it there. This one was flat and had a off taste - chalked it up to something else and dumped the batch (only time I have ever done that!) as I had only a single keg at this point and wanted to get something good in it!

2 - I set it again at 30psi for a couple of days and dialed it down to 10psi. At first I thought I might have over carbed it as there was an off taste. So I followed the process I read in a few places to let it get warm and pull the pressure pin throughout a couple of days. I then put it back in the fridge set at 12psi. While drinkable there was something off with the carbonation the whole batch.

3 - I kegged this batch 6 days ago (brewed it 9/9) and set it at 12psi thinking I am not in a rush at all with this (who am I kidding, I want to drink it!). While pouring today there is a decent head, but the beer still tastes flat. The flavor and aroma is also not as nice as it was before going into the keg.

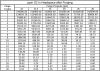

What should I be doing or checking in my system? I used the carb charts to set it at 12 psi, but none of the charts I found mention how long it takes to get fully carbed up. Am I being impatient? Should I be doing this another way?

So I am three batches into kegging and I am drinking flatish beer. I have read quite a lot of how to carb, but hoping someone can point to the error in my ways. When done with fermentation I hook up my hose to the fermentor and then rack directly to my keg. For my keg set up I am using a ball lock corny keg with 10 feet of 3/16" connected to a picnic tap in a fridge in the mid 40's. Here is what I did with each of the three batches:

1 - I set it at 30 psi for a few days and then dialed it down to 10 leaving it there. This one was flat and had a off taste - chalked it up to something else and dumped the batch (only time I have ever done that!) as I had only a single keg at this point and wanted to get something good in it!

2 - I set it again at 30psi for a couple of days and dialed it down to 10psi. At first I thought I might have over carbed it as there was an off taste. So I followed the process I read in a few places to let it get warm and pull the pressure pin throughout a couple of days. I then put it back in the fridge set at 12psi. While drinkable there was something off with the carbonation the whole batch.

3 - I kegged this batch 6 days ago (brewed it 9/9) and set it at 12psi thinking I am not in a rush at all with this (who am I kidding, I want to drink it!). While pouring today there is a decent head, but the beer still tastes flat. The flavor and aroma is also not as nice as it was before going into the keg.

What should I be doing or checking in my system? I used the carb charts to set it at 12 psi, but none of the charts I found mention how long it takes to get fully carbed up. Am I being impatient? Should I be doing this another way?