I have been brewing quite a few lagers of late. Many traditional lager brewing methods involve step-mashing. This is of course not exclusive to lagers. Other examples of styles where step-mashing is traditionally used include Hefeweizen and Altbier.

There are reasons to incorporating a step mash into your brew-day. Equally there are plenty of well-versed and respected home-brewers that will argue there is little benefit if any, to using one. The purpose of this post is merely to illustrate the process, not to explore the science.

Three assumptions focusing on single vessel brewers are made here.

Having a metal mash-tun makes incorporating a step mash into your process a lot easier. This is arguably one added bonus to BIAB. One that I feel is largely under-utilized by the majority of BIAB'ers.

Four ways to carry out a step-mash

My Stove-top setup for step mashing

Step mash via direct heating

If step mashing via direct heating, the mash must be stirred constantly while heat is applied. A mash is a poor conductor of heat. Stirring prevents scorching or uneven heating while also avoiding over-shooting the desired rest temperatures.

When step mashing this way I find it best to kill the heat a degree or two shy of your planned rest temperature. The residual heat in the pot will continue to warm the mash the last little bit of the way.

NG stove ~18,000 BTU

It's a bit like driving up to a red light, you take the foot off the gas and allow the residual energy to coast you the rest of the way there. The biggest disadvantage to this approach is the constant attention and stirring required while applying heat to the mash. The stirring is tiresome, and with full-volume mashes, takes a lot longer with the lid off and no insulation present. Owing to its low melting point, insulating the mash-tun is not safe on my setup if applying direct heat. My heat source is natural gas. Naked flame and thin plastic Refectix do not go well together.

Infusion Step Mashing

Step mash via infusions of near boiling water requires much less work and attention from the brewer. Stirring is only needed when adding the pre-planned volumes of boiling water to reach the desired temperatures. This is my process.

Boiling water at the ready

Confirming correct rest temperature

If you carry out infusion mashes this way it is impossible to overshoot your final mash volumes, an oft touted disadvantage of infusion mashing. If you come up a bit shy on the last infusion step you can take corrective measures. The insulation is removed and directly heat applied to the mash in the same manner previously described. (One more benefit of a metal mash-tun)

Decoction Step Mashing

The third way to step-mash is via decoctions. This involves a similar principle as infusions.

Pulling the Decoction

Boiling the Decoction. Smells great!

Combined Approach to Step Mashing

I typically incorporate a combined approach when carrying out a step mash. There are pros and cons to each method. Infusions are really easy to calculate and manage, direct heating is also very accurate but more work is involved. Decoctions take a bit of experience to learn the required volumes. My software (BeerSmith) typically under estimates the required decoction volume on my setup.

One other point to make about decoctions is that in my limited experience it seems to lower the mash pH a little resulting in a lower measured mash pH than planned pH by about 0.1 Something to consider during planning adjustments to mash pH.

Mash pH is measured at full volume

A recent combined approach step-mash profile used for a German Pilsner.

Description of Pilsner profile: Infusions used to target each rest temperature and direct heating to reach a short mash-out rest.

And another recent combined approach for a Vienna Lager

Description of Vienna Lager profile: Dough in to hit a short high temperature protein rest, (I will no longer be doing that type of rest), Infusion to reach Beta amylase Rest, single decoction to reach Alpha amylase rest temperature and direct heating to mash-out*.

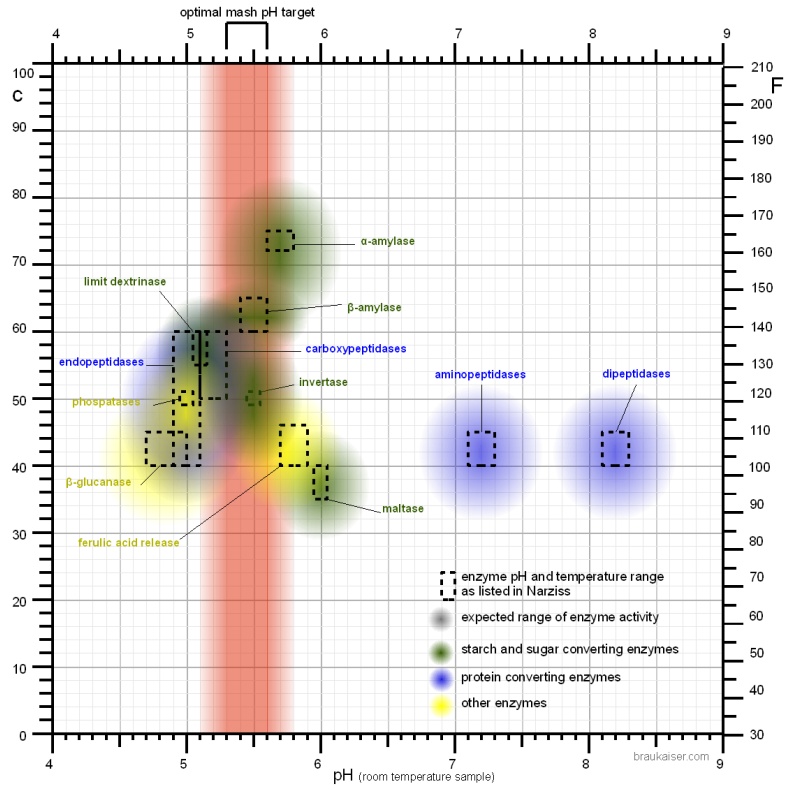

*Note: The names of the rests are not entirely accurate, donating the dominant enzyme at work.

Step-mashing is fun to do and is purported by some to add complexity to a beer's mouthfeel. I enjoy the added planning and measurement that's needed for a step-mash.

If adding a little complexity and additional time to your brew-day is something that doesn't phase you, I would encourage experimenting with step-mashing. I believe a precise and calibrated thermometer to be indispensable if step-mashing.

I hope this post might encourage others to try out this type of mashing and see for yourself what it can do for your beer.

NB:I am not doing these mashes to seek any improvement in efficiency. There is no difference on my setup between simple and complex mash profiles in this regard.

There are reasons to incorporating a step mash into your brew-day. Equally there are plenty of well-versed and respected home-brewers that will argue there is little benefit if any, to using one. The purpose of this post is merely to illustrate the process, not to explore the science.

Three assumptions focusing on single vessel brewers are made here.

- You have decided to incorporate a step-mash

- You do not have a RIMS setup

- You have access to a second smaller pot and an available secondary heat source

Having a metal mash-tun makes incorporating a step mash into your process a lot easier. This is arguably one added bonus to BIAB. One that I feel is largely under-utilized by the majority of BIAB'ers.

Four ways to carry out a step-mash

- Directly heating the tun

- Infusions of Boiling water

- Decoction mashing

- A Combined approach using some or all of the above

My Stove-top setup for step mashing

Step mash via direct heating

If step mashing via direct heating, the mash must be stirred constantly while heat is applied. A mash is a poor conductor of heat. Stirring prevents scorching or uneven heating while also avoiding over-shooting the desired rest temperatures.

When step mashing this way I find it best to kill the heat a degree or two shy of your planned rest temperature. The residual heat in the pot will continue to warm the mash the last little bit of the way.

NG stove ~18,000 BTU

It's a bit like driving up to a red light, you take the foot off the gas and allow the residual energy to coast you the rest of the way there. The biggest disadvantage to this approach is the constant attention and stirring required while applying heat to the mash. The stirring is tiresome, and with full-volume mashes, takes a lot longer with the lid off and no insulation present. Owing to its low melting point, insulating the mash-tun is not safe on my setup if applying direct heat. My heat source is natural gas. Naked flame and thin plastic Refectix do not go well together.

Infusion Step Mashing

Step mash via infusions of near boiling water requires much less work and attention from the brewer. Stirring is only needed when adding the pre-planned volumes of boiling water to reach the desired temperatures. This is my process.

Boiling water at the ready

- The full water volume is collected in the boil-kettle. Minerals and sodium metabisulfite are added to the water to target the desired mineral profile and to eliminate chloramines respectively.

- Water is drawn off to a second pot providing sufficient volume of water to be boiled and added to raise the mash temperature to the desired rest temperatures.

- Strike water is heated to target and dough-in carried out as normal hitting the first rest temperature.

- The previously collected infusion water is brought to a boil concurrently. (Keep the pot lid on and keep it at a gentle simmer to ensure boiling temperature is maintained)

- Add pre-calculated volumes of this boiling water to the main mash stirring thoroughly to ensure homogeneity of the mash and representative temperature readings.

- This method allows the mash to be kept insulated throughout.

- This is also a suitable approach to step-mashing if using a cooler as a mash-tun

Confirming correct rest temperature

If you carry out infusion mashes this way it is impossible to overshoot your final mash volumes, an oft touted disadvantage of infusion mashing. If you come up a bit shy on the last infusion step you can take corrective measures. The insulation is removed and directly heat applied to the mash in the same manner previously described. (One more benefit of a metal mash-tun)

Decoction Step Mashing

The third way to step-mash is via decoctions. This involves a similar principle as infusions.

- A thick portion of the mash is removed to a second pot. This is the decoction.

- An optional step is to carry out a conversion rest on the decoction itself before heating to a boil and return it to the main mash.

- The decoction is heated and brought to a boil and boiled for a period of time.

- The decoction is then returned to the main mash raising its temperature to the next planned rest temperature.

- This process can be repeated as needed.

Pulling the Decoction

Boiling the Decoction. Smells great!

Combined Approach to Step Mashing

I typically incorporate a combined approach when carrying out a step mash. There are pros and cons to each method. Infusions are really easy to calculate and manage, direct heating is also very accurate but more work is involved. Decoctions take a bit of experience to learn the required volumes. My software (BeerSmith) typically under estimates the required decoction volume on my setup.

One other point to make about decoctions is that in my limited experience it seems to lower the mash pH a little resulting in a lower measured mash pH than planned pH by about 0.1 Something to consider during planning adjustments to mash pH.

Mash pH is measured at full volume

A recent combined approach step-mash profile used for a German Pilsner.

Description of Pilsner profile: Infusions used to target each rest temperature and direct heating to reach a short mash-out rest.

And another recent combined approach for a Vienna Lager

Description of Vienna Lager profile: Dough in to hit a short high temperature protein rest, (I will no longer be doing that type of rest), Infusion to reach Beta amylase Rest, single decoction to reach Alpha amylase rest temperature and direct heating to mash-out*.

*Note: The names of the rests are not entirely accurate, donating the dominant enzyme at work.

Step-mashing is fun to do and is purported by some to add complexity to a beer's mouthfeel. I enjoy the added planning and measurement that's needed for a step-mash.

If adding a little complexity and additional time to your brew-day is something that doesn't phase you, I would encourage experimenting with step-mashing. I believe a precise and calibrated thermometer to be indispensable if step-mashing.

I hope this post might encourage others to try out this type of mashing and see for yourself what it can do for your beer.

NB:I am not doing these mashes to seek any improvement in efficiency. There is no difference on my setup between simple and complex mash profiles in this regard.