alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

I haven't had a chance to try the latest commit with the change to the setting acceleration. Looking forward to it.

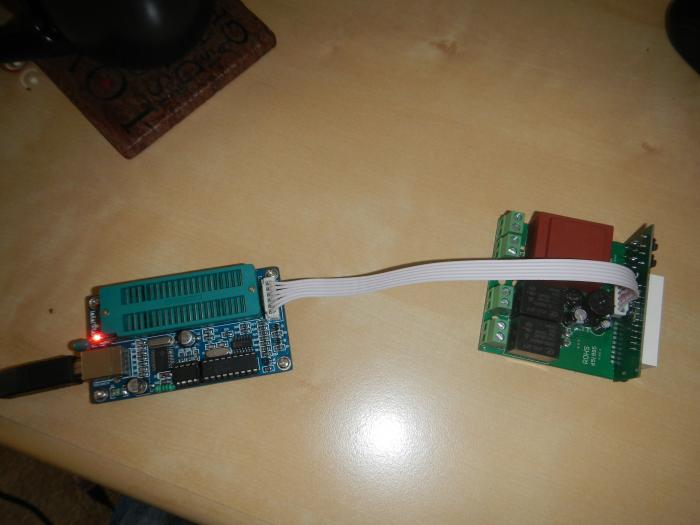

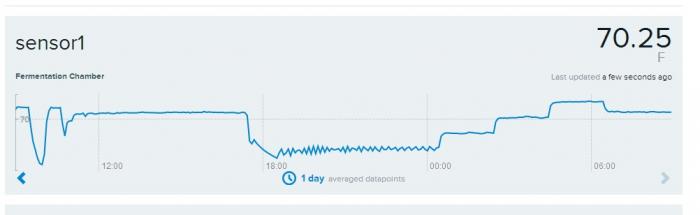

I'm out of town this weekend, but I did set up a 10 step program to cover a 72 hour period. BrewPi is logging it in a dorm fridge.

Daredevil. I hope your fridge is still functional when you get home....

And I think you'll like it when you try it. Perhaps there somw tweaking of the acceleration and speed left. But oh yeah, I pretty satisfied with the solution.